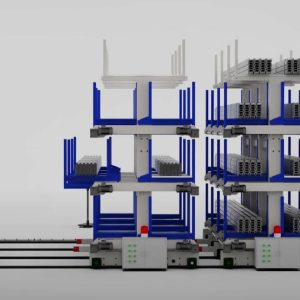

Pull-out long goods racks

The Herochu pull-out rack system is built upon a foundation of heavy-duty steel construction, designed to withstand the substantial loads and constant use of an industrial environment. The system’s intelligence lies in its movement mechanism. Unlike fixed cantilever racks, each layer of a Herochu rack is mounted on a series of high-capacity rollers and precision guides, allowing entire tiers to be extended smoothly into the aisle. This design provides clear, overhead access to the full length of the stored material, facilitating easy handling by bridge cranes, gantries, or forklifts. The key to its stability is the counterbalanced design and the inclusion of integrated braking systems, which prevent unintended movement and ensure the rack remains stable when fully extended, even under maximum load.

Optimizing Workshop Logistics: A Technical Overview of Herochu Pull-Out Long Goods Racks

The storage and retrieval of long, cumbersome materials such as steel tubes, structural profiles, solid bars, and plastic extrusions present a unique set of challenges in any industrial workshop. Traditional static racking often forces workers to maneuver heavy, unwieldy items from deep within a storage bay, a process that is not only time-consuming but also fraught with risks to both personnel and the materials themselves. Inefficient handling leads to significant productivity losses, potential damage to expensive stock, and elevated safety concerns. The Herochu series of pull-out long goods racks is engineered specifically to address these operational inefficiencies head-on. This system transforms a traditionally problematic area of the workshop into a model of efficiency, safety, and space optimization. By integrating a dynamic pull-out mechanism with a robust structural design, these racks provide direct, ergonomic access to every item, effectively eliminating the wasted time and physical strain associated with conventional storage methods.

Core Engineering Principles and Model Specifications

The Herochu pull-out rack system is built upon a foundation of heavy-duty steel construction, designed to withstand the substantial loads and constant use of an industrial environment. The system’s intelligence lies in its movement mechanism. Unlike fixed cantilever racks, each layer of a Herochu rack is mounted on a series of high-capacity rollers and precision guides, allowing entire tiers to be extended smoothly into the aisle. This design provides clear, overhead access to the full length of the stored material, facilitating easy handling by bridge cranes, gantries, or forklifts. The key to its stability is the counterbalanced design and the inclusion of integrated braking systems, which prevent unintended movement and ensure the rack remains stable when fully extended, even under maximum load.

The product line is categorized into distinct models to suit various operational scales. The HC-G6053S and HC-G6053D models are engineered for 6-meter long materials, with a single-layer load capacity of 3 tonnes. The distinction between the ‘S’ (Single-side power-assisted) and ‘D’ (Double-side power-assisted) variants refers to the configuration of the movement mechanism, offering flexibility based on workshop layout and access requirements. For larger-scale storage needs, the HC-G9055S and HC-G9055D models accommodate 9-meter lengths, with the HC-G9055S boasting an impressive 5-tonne per layer capacity. Each model features a standardized column spacing and a low height from the ground of 330mm, ensuring a low center of gravity for superior stability. The top height varies between approximately 3 and 3.8 meters, making efficient use of vertical space without compromising accessibility.

Operational Workflow Transformation and Ergonomic Benefits

The primary advantage of the pull-out system is its direct impact on daily workflow. Consider a typical scenario where a worker needs to retrieve a specific steel beam from the middle of a static rack. This would involve moving several other beams, a process that requires crane time, poses a significant safety risk, and often results in scratches and damage to the material’s surface. With a Herochu pull-out rack, the operative simply engages the power-assisted mechanism to slide the entire layer out. The aisle space becomes a temporary, dedicated work zone where the required beam is immediately accessible and can be lifted straight out without disturbing adjacent items.

This workflow transformation yields substantial benefits. Retrieval times are slashed, sometimes by as much as 80%, directly accelerating production cycles and improving on-time order fulfillment. The ergonomic impact is equally critical; the system eliminates the need for strenuous bending, reaching, and manual shifting of heavy materials, significantly reducing physical fatigue and the potential for musculoskeletal injuries among staff. Furthermore, by preventing material-on-material contact during retrieval, the racks preserve the pristine condition of stocked items, eliminating costly waste from scratches, dings, or bending, which is especially important for pre-finished materials or high-tolerance components.

Customization: Tailoring the System to Precise Operational Demands

Acknowledging that no two workshops have identical requirements, the Herochu system is fundamentally designed for customization. While the standard models provide an excellent foundation, the system’s parameters are highly adaptable. The note that “load-bearing capacity, length, number of layers, and layer height can be customized” is a core tenet of the product’s design philosophy. This means that a fabricator specializing in short-run jobs requiring quick access to a variety of small-diameter tubes can have a system built with more, closely-spaced layers. In contrast, a structural steel supplier handling large, heavy I-beams would opt for a configuration with fewer layers but a significantly higher load capacity per tier.

The compartments themselves are also variable, with available depth and height dimensions of 600x400mm, 600x600mm, and 800x600mm, allowing for logical organization of different material types. The choice between manual and electric operation provides another layer of customization. Manual systems offer a cost-effective solution for workshops with lower frequency of access, while electrically-assisted systems can further reduce physical effort and handling time in high-throughput environments. This level of tailor-made engineering ensures that the storage solution is a perfect fit for the specific workflow, space constraints, and inventory profile of the business, starting at a accessible price point of $3,698 for a base configuration.

Certification, Safety, and Integration into the Modern Workshop

Beyond performance and customization, the Herochu pull-out rack system is distinguished by its adherence to the highest international standards. The possession of CE, EU, and ISO 9001 certifications is not merely a administrative detail; it is a verifiable guarantee of quality and safety. The ISO 9001 certification, in particular, confirms that the entire manufacturing process—from material sourcing and structural calculation to welding and final assembly—is governed by a rigorous quality management system. This provides workshop managers with the confidence that the equipment they are installing is capable of performing safely under the demanding conditions of daily industrial use.

The integration of such a system transforms long goods storage from a persistent operational headache into a strategic asset. The benefits of increased storage density, enhanced accessibility, improved material preservation, and superior workplace safety contribute directly to the bottom line. The return on investment is realized through reduced labor costs, lower material waste, fewer workplace incidents, and an overall more streamlined and productive operation. For any business serious about optimizing its material handling processes, the Herochu pull-out long goods rack represents a logical and highly effective investment in operational excellence. To discuss a customized solution for your specific requirements, contacting the Herochu engineering team is the first step toward transforming your workshop’s efficiency and safety.

Q1: What steps should I take to start the procurement process?

Q2: How can I inform you of my need for suitable shelves?

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

Q4: Do you offer on-site installation and debugging services?

Q5: What measures do you take to ensure product quality?

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Q7: How can I verify your company’s strength?

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

PRODUCTS

-

Heavy Duty Cantilever Racking System

Long Goods Heavy Duty Cantilever Rack

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

New & Used Cantilever Racks | Heavy-Duty Storage Systems

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Heavy Duty Cantilever Racking System & Shelves

Read moreRated 0 out of 5 -

Sheet Metal Storage Racks

Heavy-Duty Steel Plate Organizer Shelf Drawer-Type Sheet Storage racks

Read moreRated 0 out of 5