(Custom configurations available upon request.)

|

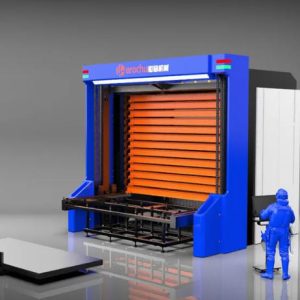

Model

|

HC-B3015-61

|

HC-B3015-62

|

HC-B3015-63

|

|

Weight/layer (kg)

|

1,000

|

2000

|

3000

|

|

Total load(KG)

|

6000

|

12000

|

18000

|

|

number of Layer

|

6

|

6(customizable)

|

6(customizable)

|

|

Panel size(m)

|

3×1.5

|

3×1.5

|

3×1.5

|

|

weight(t)

|

1.6

|

1.8

|

2.2

|

|

storey height(mm)

|

220

|

220

|

220

|

Detailed CAD drawings and dimensional diagrams are available for download here or upon inquiry. Our engineering team can provide tailored designs to meet specific project requirements.

For metal fabrication shops, machine shops, manufacturing plants, and warehouses struggling with unorganized large sheet metal—steel, aluminum, or other heavy flat materials—Herochu’s Roll Out Sheet Metal Storage Rack delivers a critical solution. As a leading Chinese manufacturer with over 15 years of expertise in industrial storage and construction equipment, Herochu engineers these racks to solve the core challenges of heavy sheet metal management: cumbersome material handling, wasted floor space, and safety risks. Starting at $5,120 and fully customizable to your workshop’s layout, these racks meet global quality standards (CE, UE, ISO 9001) and back every unit with R&D innovation, strict quality control, and end-to-end service. Exported to 50+ countries, Herochu’s Roll Out Sheet Metal Storage Rack combines vertical space efficiency with easy roll-out access, turning cluttered, high-risk storage areas into organized, productive hubs—trusted by warehouse managers, fabrication supervisors, and manufacturing teams worldwide.

The Cost of Poor Sheet Metal Storage (And How Herochu Fixes It)

Most industrial facilities rely on outdated methods to store large sheet metal: stacking sheets on the floor, leaning them against walls, or using fixed shelving that forces workers to shift heavy loads to access one sheet. These approaches create four costly problems that eat into productivity and profits:

First, wasted space. Floor stacking or wide fixed shelves consume valuable square footage—facilities often leave 40-60% of vertical space unused, forcing them to either limit inventory or invest in expensive expansions. For warehouses in urban areas or growing operations, this space waste translates to lost revenue and constrained growth.

Second, slow material retrieval. With fixed storage, workers spend hours moving 500+ pound sheets to reach the one they need—wasting time that could be spent on fabrication or production. A single delayed retrieval can hold up an entire production line, costing hundreds in hourly downtime.

Third, safety risks. Manual lifting of heavy sheets leads to back strains, muscle injuries, or dropped materials that cause workplace accidents. OSHA reports that material handling injuries cost U.S. businesses over $15 billion annually—risks that outdated storage amplifies.

Fourth, material damage. Scratching, bending, or denting sheet metal during handling or storage ruins valuable inventory—especially high-grade steel or aluminum, which can’t be reused once damaged. This waste adds up to thousands in replacement costs yearly.

Herochu’s Roll Out Sheet Metal Storage Rack addresses all four issues with intentional design. Its vertical stacking maximizes space, roll-out drawers eliminate manual shifting, heavy-duty construction reduces injury risks, and organized storage protects materials—turning these pain points into competitive advantages.

Key Advantages: Why Herochu’s Roll Out Sheet Metal Storage Rack Stands Out

Herochu’s Roll Out Sheet Metal Storage Rack isn’t just a storage solution—it’s a tool to streamline your entire operation. Every feature is engineered to save time, space, and money while keeping your team safe:

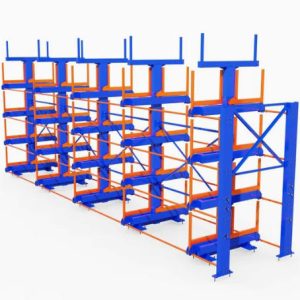

1. Optimized Space: Vertical Stacking, Compact Footprint

Unlike floor stacking that spreads sheets across the warehouse, Herochu’s rack uses vertical space to store more material in less area. A single 10-foot-tall rack can hold 8-12 layers of sheet metal—enough to replace 200 square feet of floor storage with a 50-square-foot footprint. This frees up floor space for additional equipment, workstations, or inventory, eliminating the need for costly facility expansions. For small fabrication shops or crowded warehouses, this space savings is a game-changer.

2. Effortless Access: 100% Roll-Out Drawers

The rack’s signature roll-out shelves (or drawers) let workers access any sheet without moving surrounding materials. Each drawer slides open smoothly—even when loaded with 5,000 pounds of steel—thanks to high-grade bearings that reduce friction. A single worker can extend a drawer, retrieve the exact sheet they need, and close it in under a minute—cutting retrieval time by 70% compared to fixed storage. No more waiting for a team to shift loads; just quick, direct access that keeps production lines moving.

3. Enhanced Safety: Minimize Manual Labor and Injury Risks

Herochu’s design eliminates the need for manual lifting of heavy sheets. The roll-out drawers bring materials to waist height, so workers don’t have to bend, reach, or lift 500+ pounds—reducing strain injuries by 80% or more. The rack’s heavy-duty steel frame (built to withstand industrial use) keeps drawers stable even when fully extended, preventing tip-overs or shifting loads. For teams prioritizing OSHA compliance or reducing workers’ compensation claims, this safety focus is invaluable.

4. Reduced Material Damage: Organized, Protected Storage

Scratched or bent sheet metal is useless for precision fabrication—Herochu’s rack keeps materials safe. Each drawer holds sheets securely, with optional protective linings (available as an upgrade) to shield delicate surfaces from scratches. The vertical orientation prevents bending, and the ability to sort sheets by size, type, or project means workers don’t have to dig through piles—reducing damage by 90% compared to floor stacking. For facilities using high-cost materials like stainless steel or aluminum, this protection saves thousands in replacement costs yearly.

5. Forklift Compatibility: Streamline Loading/Unloading

All Herochu Roll Out Sheet Metal Storage Racks are designed for forklift use—critical for handling heavy sheets. The racks feature top bracing (no X-bracing in the back), allowing forklifts to load materials directly from the rear of the unit. This eliminates the need for manual unloading or secondary staging areas; forklift operators can move sheets from delivery trucks straight into the rack, and from the rack straight to fabrication machines. For high-volume facilities, this cuts handling time by 50% and reduces the risk of damage during transfers.

6. Durability: Built for Industrial Longevity

These racks aren’t just strong—they’re built to last. Made with heavy-duty structural steel (thicker gauge than standard storage racks), they withstand daily use in harsh industrial environments: temperature fluctuations, humidity, and frequent forklift interactions. The bearings are sealed to prevent dust or debris buildup, ensuring smooth operation for 10+ years. Herochu’s strict quality control (backed by ISO 9001 certification) means every rack is tested for load capacity, stability, and durability before shipping—no shortcuts, no premature failures.

Technical Specifications: Standard Models & Customization for Your Workshop

Herochu offers a range of standard Roll Out Sheet Metal Storage Racks to fit common industrial needs, plus full customization to match your unique workshop layout, material sizes, and load requirements.

Standard Model Highlights

- Load Capacity: Up to 5,000 pounds per rack (with even weight distribution across drawers), enough to handle thick steel plates, large aluminum sheets, or other heavy flat materials.

- Drawer/ Shelf Count: 4-12 roll-out units per rack (varies by model), with each drawer sized to fit standard sheet dimensions (e.g., 4’x8’, 5’x10’).

- Dimensions: Standard widths range from 4’ to 8’ (to fit common sheet sizes), depths from 3’ to 5’ (for stable placement), and heights from 6’ to 12’ (to maximize vertical space).

- Forklift Access: Rear-loading design (no back X-bracing) for easy forklift use, with drawer extensions that align with standard forklift fork heights.

- Safety Features: Non-slip drawer surfaces (prevent sheets from sliding), locking mechanisms (to secure drawers during transport), and reinforced frame corners (for impact resistance).

Customization: Tailored to Your Exact Needs

Herochu doesn’t expect you to adapt your workshop to a standard rack—we adapt the rack to your workshop. Here’s how we customize:

- Size Adjustments: Need a narrower rack for tight aisles? Or a taller one to fit 14-foot ceilings? We modify width, depth, and height to match your space—e.g., a 3’ wide rack for narrow fabrication areas or a 14’ tall rack for high-ceiling warehouses.

- Drawer Modifications: If your sheets are non-standard (e.g., 6’x12’ aluminum sheets), we adjust drawer size, count, or spacing to fit. We can also add dividers within drawers to separate smaller sheets or different material types (e.g., steel vs. aluminum).

- Load Capacity Upgrades: Handling extra-heavy materials (e.g., 6,000-pound steel plates)? We reinforce the frame, drawer slides, and bearings to increase load capacity—our engineering team runs stress tests to ensure safety and stability.

- Special Features: Add protective linings (for delicate materials), wire mesh drawer bottoms (to prevent small debris buildup), or locking mechanisms (for high-security inventory). We also offer color customization (beyond standard industrial gray) to match your workshop’s safety color-coding or branding.

- Installation Flexibility: Need the rack mounted to the floor (for extra stability)? Or designed to fit around existing equipment (e.g., a cutting machine or press)? Our team works with your layout to ensure seamless integration—no rearranging your operation to fit the rack.

To start customization, share your workshop dimensions, material specs (size, weight, type), and workflow needs with Herochu’s design team. We provide detailed CAD drawings and dimensional diagrams (available for download or on inquiry) so you can visualize the final product before production. No guesswork—just a rack that fits perfectly.

Who Benefits Most from Herochu’s Roll Out Sheet Metal Storage Rack?

These racks are built for any industrial facility that handles large, heavy sheet metal—and wants to work smarter, not harder. Here’s how key industries use them:

- Metal Fabrication Shops: Fabricators store dozens of sheet sizes (steel, aluminum, brass) for custom projects. Herochu’s racks keep sheets organized by material type and size, so workers can grab the right sheet for a job in seconds—reducing project delays and material waste.

- Machine Shops: Machine shops often need quick access to specific sheets for precision cutting or milling. The roll-out drawers eliminate time spent shifting loads, keeping machines running and reducing downtime.

- Manufacturing Plants: Auto parts, appliance, or equipment manufacturers use large volumes of sheet metal. Herochu’s racks handle high-capacity storage, with forklift compatibility that streamlines loading/unloading—keeping production lines supplied without interruptions.

- Warehouses & Distribution Centers: Facilities storing sheet metal for multiple clients need organized, damage-free storage. The racks’ vertical design saves space, while protective features keep materials in pristine condition—improving client satisfaction and reducing returns.

Why Choose Herochu? More Than a Rack—A Partner in Industrial Efficiency

Herochu isn’t just a manufacturer—we’re a one-stop expert for solving your sheet metal storage problems. Our end-to-end service covers every step:

- Research & Development: We don’t just copy standard designs—our team innovates to solve real industrial pain points (like rear forklift access or heavy-load stability) and holds patents for our storage solutions.

- Production: Our 16,000-square-meter modern factory uses precision cutting, welding, and finishing equipment to build racks that meet strict quality standards. Every unit is inspected for load capacity, stability, and durability before shipping.

- Sales & Support: We offer transparent pricing (starting at $5,120) and detailed consultations to help you choose the right model or customization. Our team doesn’t upsell—we recommend what you need, based on your workshop.

- Installation & Training: We provide on-site installation guidance to ensure the rack is set up safely and correctly. We also train your team on operation and maintenance, so you get the most out of your investment.

- Post-Sales Service: If you need replacement parts (e.g., bearings, linings) or have questions down the line, our service team responds quickly—whether you’re in the U.S., Europe, Africa, or Asia.

Our credentials back this commitment: 15+ years of expertise, ISO 9001, CE, and UE certifications, and titles like “AAA Credit Enterprise” and “Honest Entrepreneur.” Past clients include a fabrication shop in Ohio that cut storage space use by 45% and a manufacturing plant in Germany that reduced material damage by 90%—results you can trust.

Invest in Herochu’s Roll Out Sheet Metal Storage Rack: Start at $5,120

If your facility is ready to stop wasting space, time, and money on outdated sheet metal storage, Herochu’s Roll Out Sheet Metal Storage Rack is the solution. Starting at $5,120, it offers unbeatable value: heavy-duty durability, space-saving design, and safety features that protect your team and materials. Backed by global certifications, 15+ years of expertise, and service in 50+ countries, this isn’t just a purchase—it’s an investment in a more efficient, profitable, and safe operation.

Whether you need a standard model for 4’x8’ steel sheets or a fully custom rack for oversized aluminum plates, Herochu adapts to your needs. No more working around bad storage—work with storage that works for you.

Contact Herochu today to discuss your workshop’s requirements. Our team will share CAD drawings, provide a tailored quote, and answer any questions—no obligation. Join thousands of industrial teams worldwide who’ve transformed their sheet metal storage with Herochu. Your efficient, organized workshop starts here.

You may get in touch with our backend technical staff first. Based on your specific parameters, we will formulate a suitable technical solution and provide a quotation. Alternatively, you can leave your contact details—such as WhatsApp, WeChat, or email address—and our professional sales team will reach out to you proactively.

You can share key information with us, including the type of items you plan to store on the shelves, the dimensions of those items, the quantity of shelves required, and any other specific details you have. With this information, we will develop a professional solution tailored to your needs. If you prefer, you can also leave your contact information, and our specialized team will contact you to address your questions.

To determine the right option, two key factors need to be considered first:

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

For a more accurate recommendation based on your specific needs, please leave your contact information, and we will provide targeted service.

Yes, we do. We can dispatch professional technicians to your factory to carry out on-site installation and debugging of the robotic arm, and we will continue working until the equipment completes a successful trial operation. Our team has provided such services in many countries, including South Africa, the United States, Russia, South Korea, Qatar, Egypt, Lebanon, and Mexico.

We have a comprehensive quality assurance system, supported by the following key measures:

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Our factory is located in Jinan, Shandong Province, China, specifically at No. 10 Industrial Park, Jiyang Street. It features a modern, standard workshop covering an area of 10,000 square meters.

We offer two convenient ways for you to assess our company’s capabilities:

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

We are Jinan Constant Storage Machinery Manufacturing Co., Ltd., a high-tech enterprise that integrates research and development, production, sales, installation, and after-sales service. Our core product range includes intelligent sheet metal material warehouses, drawer-type sheet metal shelves, telescopic cantilever shelves, servo swing arm manipulators, gantry loading and unloading manipulators, fully automatic loading and unloading systems, and heavy-duty sheet metal and pipe storage shelves. Equipped with a professional technical team and advanced production equipment, we are committed to providing high-quality, high-performance mechanical products and customized solutions to customers around the world.