Roll Out Vertical Sheet Rack

At the core of the Herochu Roll Out Vertical Sheet Rack is a commitment to longevity—because industrial storage solutions need to withstand daily use, heavy loads, and harsh workshop conditions. The rack features a welded steel framework that provides unmatched structural integrity. Unlike flimsy bolt-together racks that loosen over time, the welded design ensures the frame stays rigid even when supporting maximum loads, preventing warping or sagging that could damage materials or pose safety risks.

Category Sheet Metal Storage Racks

Herochu Roll Out Vertical Sheet Rack: Industrial-Grade Storage for Efficient Sheet Metal Management

In industrial workshops, fabrication shops, and material handling centers, sheet metal storage is often a balancing act: you need to keep materials organized, accessible, and protected—all while making the most of limited floor space. Manual storage solutions like pallets or static racks fall short: they waste space, force workers to strain when retrieving sheets, and leave materials vulnerable to scratches, dents, or loss. Herochu’s Roll Out Vertical Sheet Rack was engineered to fix these inefficiencies. This heavy-duty, customizable system transforms how you store sheet metal, steel bars, and long heavy goods—cutting floor space use by over 50%, simplifying retrieval, and protecting your valuable materials. Whether you’re running a small fabrication shop or a large-scale manufacturing facility, this rack turns cluttered storage areas into streamlined hubs that boost productivity and reduce waste.

Built for Industrial Durability: Materials & Construction

At the core of the Herochu Roll Out Vertical Sheet Rack is a commitment to longevity—because industrial storage solutions need to withstand daily use, heavy loads, and harsh workshop conditions. The rack features a welded steel framework that provides unmatched structural integrity. Unlike flimsy bolt-together racks that loosen over time, the welded design ensures the frame stays rigid even when supporting maximum loads, preventing warping or sagging that could damage materials or pose safety risks.

To protect against rust, corrosion, and wear, the entire rack is finished with a powder coat treatment. This industrial-grade coating creates a tough, scratch-resistant barrier that stands up to moisture, chemicals, and frequent handling—ideal for workshops where oil, metal shavings, or humidity are common. Whether you’re storing steel sheets, aluminum plates, or copper coils, the powder coat finish ensures the rack remains in top condition for years, reducing maintenance costs and extending its lifespan.

Every component—from the pull-out shelves to the guide rails—is built to industrial standards. The shelves themselves are reinforced to handle heavy loads, with side rails that support the shelf during full extension (critical for preventing bending when retrieving large sheets). The roll-out mechanism uses precision-engineered guides that ensure smooth, friction-free movement—so even fully loaded shelves glide easily, reducing strain on workers and preventing jams that disrupt workflow.

Space-Saving Vertical Design: Maximize Storage Without Expanding Your Workshop

One of the biggest challenges in industrial storage is making the most of available space. Traditional horizontal racks or pallets spread materials across the floor, wasting vertical space that could be used for additional storage or equipment. The Herochu Roll Out Vertical Sheet Rack solves this by leveraging vertical space—turning unused height into valuable storage real estate.

The rack’s vertical orientation allows it to hold 8 to 25 pull-out shelves (depending on your needs), each capable of storing sheet metal or long goods without taking up extra floor space. Compared to traditional storage methods, this design cuts floor space footprint by over 50%. For example, a workshop that previously used 200 square feet of floor space to store sheet metal can now fit the same inventory in just 90 square feet with the vertical rack—freeing up room for additional workstations, machinery, or material handling equipment.

The vertical layout also improves workflow by centralizing storage. Instead of chasing materials across the shop floor, workers can access all their sheet metal from a single, compact rack. This reduces time spent retrieving materials and minimizes the risk of accidents caused by moving heavy sheets across crowded spaces.

Heavy-Duty Performance: Load Capacity & Accessibility

Industrial storage isn’t just about space—it’s about safely supporting heavy materials. The Herochu Roll Out Vertical Sheet Rack is built to handle the demands of industrial use, with a standard load capacity of up to 2,000 lb per shelf. This means you can store thick steel sheets, dense aluminum plates, or long steel bars without worrying about shelf failure. For shops with even heavier needs, custom load options are available—so if you need to store 3,000 lb sheets for construction or heavy fabrication, we can tailor the rack to meet your requirements.

What sets this rack apart is its accessibility. Each shelf features a full-extension roll-out design that glides on ergonomic guides. When you need to retrieve a sheet, simply pull the shelf out to its full length—no more reaching over or under other materials. The full extension also provides overhead clearance for cranes, hoists, or vacuum lifts, making it easy to move heavy sheets in and out of the rack without manual lifting. This not only reduces ergonomic strain on workers (lowering the risk of injuries like back pain or muscle strains) but also speeds up material handling—cutting retrieval time by up to 30%.

To ensure safety, each shelf locks automatically when closed. This prevents accidental roll-outs that could damage materials or harm workers, even in busy workshops where carts or forklifts pass by frequently. The locking mechanism is easy to engage and disengage, so it doesn’t slow down workflow—just a simple pull or push to lock the shelf in place.

Customizable to Your Workshop: No One-Size-Fits-All Solutions

Herochu knows that every workshop has unique storage needs. A small fabrication shop storing 4x8ft sheet metal has different requirements than a large manufacturing facility handling 10ft steel bars. That’s why the Roll Out Vertical Sheet Rack is fully customizable, starting with:

- Shelf Count & Spacing: Choose from 8 to 25 shelves, and adjust the height between shelves to fit your material thicknesses. Need to store extra-thick 10mm steel sheets? We’ll widen the spacing between shelves. Storing thin 2mm aluminum sheets? We’ll narrow it to fit more shelves—maximizing storage density.

- Height & Width: The standard rack height is 7 feet, but we offer custom heights to match your workshop’s ceiling (up to 12 feet for high-ceiling facilities). Widths are also customizable—so if you need to store 6ft wide sheets, we’ll build a rack that fits, no cutting or trimming required.

- Add-Ons: Enhance the rack’s functionality with optional features like folding doors (to protect materials from dust or debris), double-sided loading (for access from both sides of the rack, ideal for busy shops), or forklift risers (to raise the rack off the ground, making it easier to load sheets with a forklift).

- Material Compatibility: While the rack is designed for sheet metal, it can be customized to store other long heavy goods—like steel bars, pipes, or even large machinery parts. We’ll adjust the shelf design (e.g., adding dividers or supports) to keep your specific materials secure.

Every customization is tested by Herochu’s engineering team to ensure it meets the same high standards of durability and safety as our standard racks. Whether you’re retrofitting an existing storage area or building a new one, we’ll design a rack that fits your space, your materials, and your workflow.

Certified Quality: CE, EU, ISO 9001—Compliance You Can Trust

When investing in industrial storage equipment, quality and safety aren’t optional—they’re essential. The Herochu Roll Out Vertical Sheet Rack meets or exceeds global standards, backed by three critical certifications:

- ISO 9001: This certification ensures consistent quality in every component, from the welded steel frame to the roll-out guides. Our manufacturing process is audited annually to maintain ISO 9001 compliance, so you know every rack is built to last. We use high-grade steel (Q235, the same material used in heavy machinery) for the frame, and industrial-grade bearings for the roll-out mechanism—ensuring smooth operation even after years of daily use.

- CE & EU: For businesses operating in the European Union or exporting to EU markets, CE compliance is mandatory. The rack meets all EU safety, health, and environmental regulations: it includes safety stops on the shelf guides (to prevent shelves from sliding out too far), and the powder coat finish is free of harmful chemicals (aligning with EU RoHS standards). It also features rounded edges to reduce the risk of cuts or scrapes—keeping workers safe.

- Rigorous Testing: Before any rack ships, it undergoes 48 hours of continuous load testing. We stack each shelf to its maximum capacity, roll shelves in and out hundreds of times, and simulate real-world use (e.g., bumping the rack with a forklift) to ensure it holds up. This testing ensures the rack works flawlessly from day one—no costly downtime or repairs after installation.

Benefits That Boost Productivity: More Than Just Storage

The Herochu Roll Out Vertical Sheet Rack isn’t just a storage solution—it’s a tool that improves every aspect of your material handling process:

- Reduce Labor Costs: By cutting retrieval time and minimizing manual lifting, the rack reduces the number of workers needed for material handling. Customers report a 20–30% drop in labor hours spent on storage-related tasks—freeing up staff for higher-value work like fabrication or quality control.

- Protect Materials: The rack’s enclosed design and smooth roll-out mechanism prevent scratches, dents, or bending that can ruin sheet metal. This reduces material waste by up to 15%—a significant savings for high-cost materials like stainless steel or titanium. For example, a shop that wastes

5,000worthofsheetmetalannuallycansave

750 a year with the rack.

- Improve Inventory Visibility: With each shelf clearly labeled and fully accessible, it’s easy to track inventory levels. No more searching for missing sheets or overordering because you can’t see what’s in stock. This minimizes waste from overstocking and prevents delays caused by stockouts.

- Enhance Ergonomics: The full-extension shelves and automatic locking reduce strain on workers. This lowers the risk of workplace injuries (which can cost thousands in medical bills and lost productivity) and improves employee satisfaction—reducing turnover in roles that involve heavy lifting.

Herochu: Your Partner in Industrial Storage

When you buy a Herochu Roll Out Vertical Sheet Rack, you’re not just purchasing a rack—you’re partnering with a team that’s invested in your success. As both a manufacturer and trader, we control every step of the process: from designing the rack to shipping it to your workshop. This vertical integration lets us offer competitive pricing (starting at $3,099) without cutting corners on quality.

Our support doesn’t end with delivery:

- Consultation: We start by learning about your workshop—your material types, storage volume, space constraints, and workflow. Our team recommends a configuration that fits your needs, no pushy sales tactics.

- Custom Design: If you need a non-standard size or add-ons, our engineers create 2D/3D drawings so you can visualize the rack before production. We adjust the design until it’s perfect for your space.

- Installation: Our certified technicians install the rack on-site, ensuring it’s level, secure, and aligned with your workflow. We also train your team on how to use and maintain the rack—with easy-to-follow guides and hands-on demonstrations.

- After-Sales Support: We offer 24/7 technical support for urgent issues. If a part needs replacement (like a guide rail or locking mechanism), we stock spare parts in global warehouses—so you get what you need in days, not weeks. We also provide annual maintenance checks to keep the rack running like new.

- OEM/ODM Services: Need to brand the rack with your company logo or integrate it with other storage systems (like Herochu’s Heavy Duty Roll Out Metal Structure Racks)? We offer OEM/ODM options to make the rack uniquely yours.

We export our racks to markets worldwide, with a track record of success in industries like automotive (Netherlands), construction (Serbia), and aerospace (South Africa). Our customer satisfaction rate is 100%—because we don’t just sell racks; we help you build more efficient, profitable operations.

Ideal Applications: Where the Rack Shines

The Herochu Roll Out Vertical Sheet Rack is versatile enough to serve a wide range of industries:

- Metal Fabrication Shops: Store sheet metal of all sizes (from 4x8ft to 10x20ft) and thicknesses, with easy access for cutting, bending, or welding. The vertical design saves floor space for worktables or machinery.

- Automotive Manufacturing: Store body panels, chassis components, or steel sheets for stamping. The full-extension shelves make it easy to load sheets into laser cutters or press brakes, reducing production delays.

- Construction: Store large sheet metal (e.g., roofing panels, siding) or long steel bars for structural work. The forklift risers option lets you load heavy materials quickly, even on busy job sites.

- Aerospace & Defense: Store delicate aluminum or titanium sheets for aircraft parts. The powder coat finish protects against corrosion, and the smooth roll-out mechanism prevents scratches—critical for meeting strict industry quality standards.

- Electronics: Store thin copper or stainless steel sheets for circuit boards or enclosures. The adjustable shelf spacing fits small, delicate sheets without wasting space.

Why Choose Herochu Over Competitors?

In a market filled with generic storage racks, the Herochu Roll Out Vertical Sheet Rack stands out for three key reasons:

- Vertical Focus: Unlike competitors who offer horizontal racks with limited vertical storage, our rack is designed specifically for vertical use—maximizing space savings and accessibility.

- True Customization: Competitors often offer “one-size-fits-most” racks with minimal adjustments; we build racks tailored to your exact needs. Whether you need a 12-foot-tall rack or a double-sided design, we don’t force you to compromise.

- Value for Money: Starting at $3,099, our rack offers more features (powder coat finish, automatic locking, custom options) than similarly priced competitors. Plus, our 100% customer satisfaction rate means you’re not just buying a rack—you’re buying peace of mind.

Ready to Transform Your Sheet Metal Storage?

Herochu’s Roll Out Vertical Sheet Rack isn’t just an investment in storage—it’s an investment in your workshop’s efficiency, profitability, and safety. By cutting floor space use, reducing labor costs, and protecting your materials, it lets you focus on what you do best: producing high-quality parts.

Contact our team today to request a free quote, schedule a virtual demo, or discuss your customization needs. We’ll help you design a rack that fits your budget, your space, and your production goals.

Herochu: Industrial Storage, Engineered for Efficiency.

Q1: What steps should I take to start the procurement process?

You may get in touch with our backend technical staff first. Based on your specific parameters, we will formulate a suitable technical solution and provide a quotation. Alternatively, you can leave your contact details—such as WhatsApp, WeChat, or email address—and our professional sales team will reach out to you proactively.

Q2: How can I inform you of my need for suitable shelves?

You can share key information with us, including the type of items you plan to store on the shelves, the dimensions of those items, the quantity of shelves required, and any other specific details you have. With this information, we will develop a professional solution tailored to your needs. If you prefer, you can also leave your contact information, and our specialized team will contact you to address your questions.

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

To determine the right option, two key factors need to be considered first:

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

For a more accurate recommendation based on your specific needs, please leave your contact information, and we will provide targeted service.

Q4: Do you offer on-site installation and debugging services?

Yes, we do. We can dispatch professional technicians to your factory to carry out on-site installation and debugging of the robotic arm, and we will continue working until the equipment completes a successful trial operation. Our team has provided such services in many countries, including South Africa, the United States, Russia, South Korea, Qatar, Egypt, Lebanon, and Mexico.

Q5: What measures do you take to ensure product quality?

We have a comprehensive quality assurance system, supported by the following key measures:

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Our factory is located in Jinan, Shandong Province, China, specifically at No. 10 Industrial Park, Jiyang Street. It features a modern, standard workshop covering an area of 10,000 square meters.

Q7: How can I verify your company’s strength?

We offer two convenient ways for you to assess our company’s capabilities:

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

We are Jinan Constant Storage Machinery Manufacturing Co., Ltd., a high-tech enterprise that integrates research and development, production, sales, installation, and after-sales service. Our core product range includes intelligent sheet metal material warehouses, drawer-type sheet metal shelves, telescopic cantilever shelves, servo swing arm manipulators, gantry loading and unloading manipulators, fully automatic loading and unloading systems, and heavy-duty sheet metal and pipe storage shelves. Equipped with a professional technical team and advanced production equipment, we are committed to providing high-quality, high-performance mechanical products and customized solutions to customers around the world.

PRODUCTS

-

Sheet Metal Storage Racks

Manual Control Roll out Sheet Metal Rack with Forklift

Read moreRated 0 out of 5 -

Sheet Metal Storage Racks

Pull Out Sheet Storage Drawer Rack Roll-Out Sheet Rack for Sheets

Read moreRated 0 out of 5 -

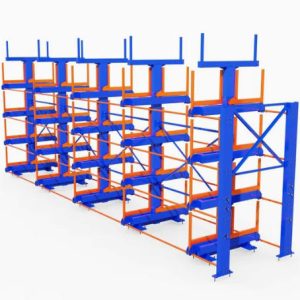

Heavy Duty Cantilever Racking System

Customizable Workshop Storage Cantilever Racking System

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Loading/unloading System for Fiber Laser Cutting Machine

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Automatic Loading and Unloading System for Fiber Laser

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Telescopic Cantilever Shelves Long Materials Storage

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Pipe Telescopic Cantilever Shelf Metal Sheet Warehouse Storage Rack

Read moreRated 0 out of 5