Steel Sheet Metal Vacuum Lifting Device

The Herochu Steel Sheet Metal Vacuum Lifting Device is a purpose-engineered solution designed to conquer these challenges comprehensively. This is not merely a lifting tool; it is a sophisticated integrated handling system that redefines material flow within a workshop. Starting at a competitive $3,698 and bearing CE, UE, and ISO 9001 certifications, the Herochu lifter represents an investment in unparalleled safety, radical efficiency gains, and the preservation of material integrity. It transforms a hazardous, multi-person task into a seamless, one-person operation, unlocking new levels of productivity.

| item | value |

| Vertical Travel(mm) | 1850mm |

| Horizonal Travel(mm) | 3000mm |

| Warranty | 1 Year |

| Place of Origin | China |

| Weight | 500 |

| Dimension(L*W*H) | 3800×1700*1700mm |

| Condition | New |

| Brand Name | Herochu |

| Power | 600w |

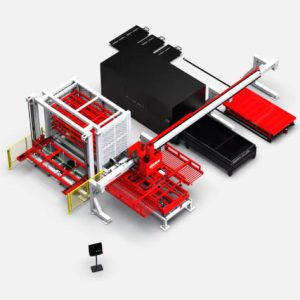

Herochu Steel Sheet Metal Vacuum Lifting Device: Engineering Superiority for Modern Fabrication

Within the core of modern manufacturing and metal fabrication, sheet metal remains a fundamental and ubiquitous material. Its application spans critical industries from automotive and aerospace to construction and consumer appliances. However, the very properties that make steel, aluminum, and stainless steel sheets so valuable—their substantial weight, smooth surface finish, and structural rigidity—also present profound handling challenges. Manual methods are inherently inefficient, dangerously labor-intensive, and pose an unacceptable risk of product damage through scratches, bending, or catastrophic drops. These operational inefficiencies directly impact productivity, safety records, and the bottom line.

The Herochu Steel Sheet Metal Vacuum Lifting Device is a purpose-engineered solution designed to conquer these challenges comprehensively. This is not merely a lifting tool; it is a sophisticated integrated handling system that redefines material flow within a workshop. Starting at a competitive $3,698 and bearing CE, UE, and ISO 9001 certifications, the Herochu lifter represents an investment in unparalleled safety, radical efficiency gains, and the preservation of material integrity. It transforms a hazardous, multi-person task into a seamless, one-person operation, unlocking new levels of productivity.

Conquering the Inherent Challenges of Sheet Metal

Sheet metal handling is fraught with difficulty. Its significant mass often renders manual lifting impossible without mechanical aid. While its broad faces are smooth, its edges can be razor-sharp, creating a handling hazard that standard hooks or clamps cannot address safely without marring the surface. Furthermore, sheet metal can exhibit slight warping or bending, making a secure, balanced grip difficult to achieve with traditional methods. The Herochu Vacuum Lifting Device eliminates these concerns entirely. By utilizing the power of controlled vacuum, it achieves a secure, distributed grip across the surface of the material. This method of engagement applies uniform pressure, preventing point-load stresses that can lead to permanent deformation, especially in thinner gauges. It handles sheets of virtually any finish without a single scratch.

Operational Principles and Robust Engineering

The operational principle of the Herochu device is based on reliable physics. High-quality, oil-resistant vulcanized rubber suction pads form an airtight seal on the sheet’s surface. An integrated, compressed air-powered vacuum pump then evacuates the air from within the sealed chambers, creating a powerful negative pressure differential. The resulting atmospheric pressure securely holds the load, with a safety factor significantly exceeding the maximum rated capacity of 600kg.

The lifter’s frame is a masterpiece of low-profile design, engineered for a lowered height that provides exceptional maneuverability under low ceilings and around overhead obstacles. The main crossbeam is pressurized, acting as its own vacuum reservoir to ensure consistent performance and rapid response. Eight suction pads are mounted on four fully adjustable arms, allowing operators to quickly reconfigure their positions along the beam to perfectly match the size, shape, and center of gravity of any sheet up to 3000x1500mm. This adaptability is crucial for maintaining perfect load balance during the entire lifting and moving process.

A Culture of Safety: Protocols and Integrated Systems

Safety is the foremost priority in the design of the Herochu lifter. Its use institutionalizes a safer working environment by removing personnel from direct contact with heavy, sharp loads. However, equipment is only one component of safety; established protocols are equally vital. Safe operation requires checking that environmental conditions are suitable and confirming the load weight does not exceed the device’s Working Load Limit (WLL).

The Herochu system incorporates multiple layers of redundant safety features to prevent accidents. An audiovisual alarm provides immediate warning if the vacuum level drops below a safe threshold. A critical non-return valve acts as a mechanical failsafe, instantly locking in the existing vacuum to prevent a load drop in the unlikely event of a power or air supply interruption. A vacuum gauge offers the operator a constant, clear visual confirmation of system status. Furthermore, a built-in filter protects the pneumatic circuit from contaminants like dust and moisture, ensuring long-term reliability. The recommended safety procedure includes a pre-use inspection of pads and components, achieving a secure vacuum, and then lifting the load a short distance of 50mm to verify stability before completing the full transport.

Specifications and Industrial Application

The Herochu Steel Sheet Metal Vacuum Lifting Device is built for endurance and performance in the most demanding industrial settings.

Key Technical Specifications:

-

Maximum Load Capacity: 600 kg

-

Liftable Sheet Format: 3000×1500 mm

-

Number of Suction Pads: 8 (adjustable)

-

Power Supply: Compressed Air

-

Vertical Travel: 1850 mm

-

Horizontal Travel: 3000 mm

-

Frame Design: Low-profile, pressurized reservoir beam

-

Overall Dimensions (LxWxH): 3800x1700x1700 mm

-

Standard Features: Adjustable suction arms, Audiovisual alarm system, Oil-resistant vulcanized rubber pads, Non-return valve, Vacuum filter, Precision vacuum gauge, Spring-loaded compensation for uneven surfaces.

-

Certifications: CE, UE, ISO 9001

-

Warranty: 1 Year

This device is indispensable for any facility involved in metal fabrication. It dramatically improves the workflow for loading and unloading punch presses, laser cutters, CNC machining centers, and press brakes. It enhances safety in warehouses and storage areas for retrieving and placing sheets on racks. By streamlining these processes, the Herochu lifter reduces cycle times, minimizes labor costs, and virtually eliminates product damage caused by handling.

Invest in Operational Excellence

The Herochu Steel Sheet Metal Vacuum Lifting Device is more than a piece of equipment; it is a strategic upgrade to your manufacturing capabilities. It fosters a safer, more efficient, and more profitable operation. By automating the most cumbersome and risky aspect of sheet metal processing, it allows your skilled workforce to focus on value-added tasks rather than manual labor.

To discover how this customizable vacuum lifting solution can be integrated into your specific workshop environment and material handling workflow, contact our engineering specialists today for a detailed consultation and quote.

Q1: What steps should I take to start the procurement process?

Q2: How can I inform you of my need for suitable shelves?

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

Q4: Do you offer on-site installation and debugging services?

Q5: What measures do you take to ensure product quality?

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Q7: How can I verify your company’s strength?

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

PRODUCTS

-

Sheet Metal Material Handling Equipment

Handling of plates and sheets, vacuum lifting

Read moreRated 0 out of 5 -

Sheet Metal Material Handling Equipment

Steel Sheet Metal Vacuum Lifting Device

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Automation loading and unloading systems for Laser Processing Machines

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Fiber Laser Automation | Automatic Loading And Unloading

Read moreRated 0 out of 5 -

Sheet Metal Material Handling Equipment

Loading & Unloading Equipment Servo swing arm handling manipulator

Read moreRated 0 out of 5