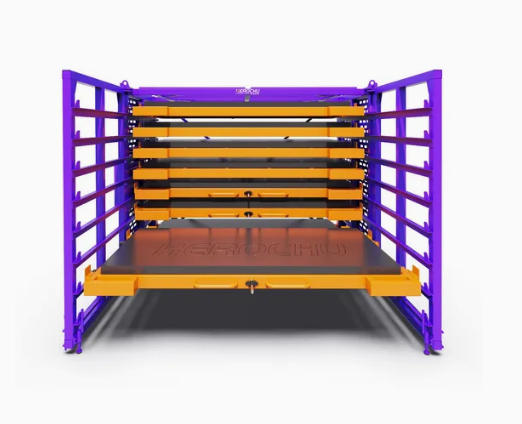

Storage steel sheets racks measuring 1500×3000 or 3500mm for 3t sheets

Herochu’s horizontal storage design flips the script by maximizing vertical space, turning unused overhead areas into efficient storage zones. Imagine freeing up enough floor space to add a new piece of machinery, expand your assembly line, or create clearer walkways for your team. That’s the power of our storage racks. By lifting steel sheets off the ground and organizing them horizontally, we eliminate clutter, reduce trip hazards, and transform cramped workshops into streamlined hubs of productivity. For small to large manufacturing facilities struggling with limited space, this isn’t just a storage upgrade—it’s a complete workspace transformation.

Transform Your Workshop with Herochu’s Industrial-Grade Steel Sheet Storage Racks

In the fast-paced world of manufacturing and metalworking, every square foot of your workshop matters—and so does every minute your team spends on material handling. Herochu’s storage steel sheets racks, available in 1500x3000mm and 1500x3500mm sizes with a 3t sheet capacity, are engineered to solve the two biggest pain points for industrial shops: wasted space and inefficient material retrieval. Starting at just $3,099, these customizable storage solutions aren’t just equipment—they’re a strategic investment in your workshop’s productivity, safety, and bottom line. Backed by CE, UE, and ISO 9001 certifications, Herochu’s racks meet the highest global standards for quality and reliability, giving you the confidence to streamline your operations without compromising on performance.

The Horizontal Storage Revolution: Reclaim Your Floor Space

Traditional sheet metal storage methods—whether scattered on wood pallets, piled on the floor, or crammed into outdated shelves—waste precious floor space and create chaotic work environments. Herochu’s horizontal storage design flips the script by maximizing vertical space, turning unused overhead areas into efficient storage zones. Imagine freeing up enough floor space to add a new piece of machinery, expand your assembly line, or create clearer walkways for your team. That’s the power of our storage racks. By lifting steel sheets off the ground and organizing them horizontally, we eliminate clutter, reduce trip hazards, and transform cramped workshops into streamlined hubs of productivity. For small to large manufacturing facilities struggling with limited space, this isn’t just a storage upgrade—it’s a complete workspace transformation.

Stackable, Adjustable, and Built to Grow With Your Business

One of the most standout features of Herochu’s steel sheet racks is their modular, future-ready design. Our 6’ (1500x3000mm) and 8’ (1500x3500mm) models are fully stackable, allowing you to create vertical storage systems up to 20’ tall for the 8’ racks and 12’ tall for the 6’ versions. This stackability means you can scale your storage capacity as your inventory grows, without needing to expand your workshop’s footprint. But flexibility doesn’t stop there—our easy bolt-together design lets you adjust shelf heights to accommodate different sheet sizes and inventory needs. Whether you’re storing thin gauge sheets or heavy 3t plates, you can customize the rack to fit your exact requirements, ensuring no space is wasted and every sheet is easily accessible.

Safety First: Protect Your Team and Your Materials

In any industrial setting, safety is non-negotiable—and Herochu’s steel sheet racks are engineered with this principle at their core. Our heavy-duty steel frame, constructed with 5” tube supports, provides unmatched stability, eliminating the risk of shifting materials that can lead to accidents or damage. Each rack comes equipped with safety pins that serve two critical purposes: they keep sheets securely in place during storage and retrieval, and they act as a visual capacity guide to prevent overloading. Additionally, our innovative cassette system—available in 3,000 lb and 5,000 lb capacity options—features strategic divots that make loading and unloading effortless with just a forklift. No more struggling with manual lifting or relying on expensive depalletizers; your team can retrieve sheets quickly and safely, reducing the risk of injuries and material damage.

Boost Efficiency and Cut Costs: The Bottom-Line Benefits

Every minute your team spends searching for misplaced sheets or struggling with awkward storage is a minute lost to productivity—and lost productivity translates to lost revenue. Herochu’s storage racks solve this problem by providing organized, systematic storage that reduces retrieval time by up to 50%. Imagine your team spending less time rummaging through piles and more time on value-adding tasks like fabrication and assembly. The impact on your bottom line is tangible: lower labor costs, faster project turnaround times, and increased output. But the savings don’t stop there. By keeping sheets organized and protected, our racks reduce material waste caused by scratches, dents, or bending. They also simplify inventory management, allowing you to see your stock at a glance and avoid over-ordering or shortages that lead to costly downtime. Over time, these small efficiencies add up to significant savings, making Herochu’s racks a smart investment for any cost-conscious workshop.

Why Choose Herochu Over Generic Storage Solutions?

There’s no shortage of storage racks on the market, but Herochu’s offerings stand out for their quality, versatility, and user-centric design. Unlike flimsy, one-size-fits-all alternatives, our racks are built to withstand the rigors of industrial use, with a bolt-together construction that ensures durability and easy maintenance. The CE, UE, and ISO 9001 certifications are a testament to our commitment to quality, giving you peace of mind that you’re investing in a product that meets global safety and performance standards. Additionally, our customizable design means we can tailor the racks to your workshop’s unique layout and inventory needs. Whether you need a compact system for a small shop or a large-scale storage solution for a high-volume manufacturing facility, we can create a setup that works for you.

Real-World Impact: From Chaos to Order

Consider the scenario of a mid-sized metal fabrication shop that was previously storing steel sheets on wooden pallets. The shop faced constant issues: sheets were easily damaged, retrieval took up to 20 minutes per job, and floor space was so limited that new equipment couldn’t be installed. After investing in Herochu’s 1500x3500mm stackable racks, the shop transformed its storage area. Sheets were organized by size and type, retrieval time dropped to less than 2 minutes, and the freed-up floor space allowed them to add a new laser cutter—increasing their production capacity by 30%. Additionally, the reduction in material waste and labor costs saved the shop over $10,000 in the first year alone. This is just one example of how Herochu’s storage racks can turn inefficiency into opportunity.

Get Started with Herochu Today

Your workshop deserves a storage solution that works as hard as your team does. Herochu’s storage steel sheets racks—available in 1500x3000mm and 1500x3500mm sizes with 3t capacity, starting at $3,099—are designed to optimize space, enhance safety, and boost productivity. With customizable options, industry-leading certifications, and a focus on cost savings, these racks are the perfect addition to any manufacturing, fabrication, or metalworking facility. Don’t let disorganized storage hold your business back. Contact our team today to discuss your workshop’s unique needs and discover how Herochu can help you create a more efficient, safe, and profitable workspace. Whether you’re looking to upgrade your current storage system or expand your capacity, we’re here to provide a tailored solution that grows with your business.

Q1: What steps should I take to start the procurement process?

You may get in touch with our backend technical staff first. Based on your specific parameters, we will formulate a suitable technical solution and provide a quotation. Alternatively, you can leave your contact details—such as WhatsApp, WeChat, or email address—and our professional sales team will reach out to you proactively.

Q2: How can I inform you of my need for suitable shelves?

You can share key information with us, including the type of items you plan to store on the shelves, the dimensions of those items, the quantity of shelves required, and any other specific details you have. With this information, we will develop a professional solution tailored to your needs. If you prefer, you can also leave your contact information, and our specialized team will contact you to address your questions.

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

To determine the right option, two key factors need to be considered first:

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

For a more accurate recommendation based on your specific needs, please leave your contact information, and we will provide targeted service.

Q4: Do you offer on-site installation and debugging services?

Yes, we do. We can dispatch professional technicians to your factory to carry out on-site installation and debugging of the robotic arm, and we will continue working until the equipment completes a successful trial operation. Our team has provided such services in many countries, including South Africa, the United States, Russia, South Korea, Qatar, Egypt, Lebanon, and Mexico.

Q5: What measures do you take to ensure product quality?

We have a comprehensive quality assurance system, supported by the following key measures:

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Our factory is located in Jinan, Shandong Province, China, specifically at No. 10 Industrial Park, Jiyang Street. It features a modern, standard workshop covering an area of 10,000 square meters.

Q7: How can I verify your company’s strength?

We offer two convenient ways for you to assess our company’s capabilities:

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

We are Jinan Constant Storage Machinery Manufacturing Co., Ltd., a high-tech enterprise that integrates research and development, production, sales, installation, and after-sales service. Our core product range includes intelligent sheet metal material warehouses, drawer-type sheet metal shelves, telescopic cantilever shelves, servo swing arm manipulators, gantry loading and unloading manipulators, fully automatic loading and unloading systems, and heavy-duty sheet metal and pipe storage shelves. Equipped with a professional technical team and advanced production equipment, we are committed to providing high-quality, high-performance mechanical products and customized solutions to customers around the world.

PRODUCTS

-

Heavy Duty Cantilever Racking System

Cantilever Racks & Heavy-Duty Shelf Systems for Warehouses

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Industrial Roll-out Telescopic Cantilever Rack

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Storage solution for long timber packs

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Heavy duty Storage racks for steel profiles

Read moreRated 0 out of 5 -

Sheet Metal Storage Racks

Storage steel sheets racks measuring 1500×3000 or 3500mm for 3t sheets

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Optimizing Warehouse Efficiency with Pipe Racking systems

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Industry Pipe Storage and Racking Solutions

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Cantilever Steel Bar, Tubing & Pipe Storage Racks

Read moreRated 0 out of 5