|

Model

|

HC-G6053S

|

HC-G6053D

|

HC-G9055S

|

HC-G9055D

|

|

Load (single layer)

|

3t

|

3t

|

5t

|

3t

|

|

Tube Length

|

6m

|

6m

|

9m

|

9m

|

|

Layers

|

|

|

Available dimensions of compartment

|

Depth * Height: 600×400,600×600,800×600 mm

|

|

Overall dimensions/mm

|

6435x3340x1550

|

6435x3340x1750

|

9435x3340x1550

|

9435x3340x1750

|

|

|

Single-side power-assisted type

|

Double-side power-assisted type

|

Single-side power-assisted type

|

Double-side power-assisted type

|

|

Height from the ground

|

330mm

|

|

Top floor height from ground

|

3040mm

|

3840mm

|

|

Column spacing

|

1800mm

|

1500mm

|

Note: Both manual and electric can be customized, and the load-bearing capacity, length, number of layers, and layer height can be customized. |

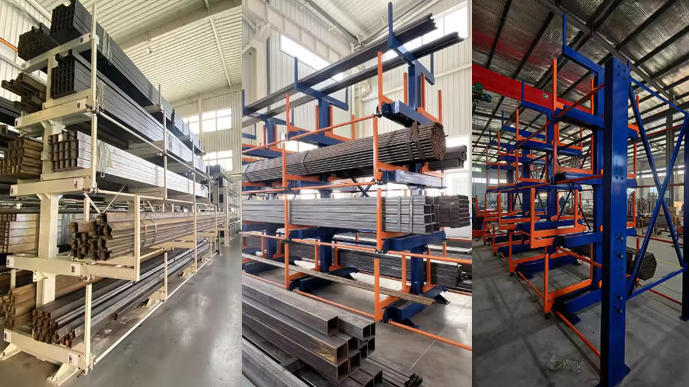

For industries handling pipes, beams, profiles, or rods—from metal fabrication to construction—storing long materials is a unique challenge. These elongated, often heavy items waste space when haphazardly leaned against walls, risk bending or scratching when stacked incorrectly, and slow workflows when retrieval requires moving entire bundles. Herochu’s Storage Systems for Long Material solve these pain points, combining precision engineering, customizable design, and global certifications to transform how you manage long goods. Starting at $3,698 and backed by CE, EU, and ISO 9001 credentials, our systems turn disorganized storage into a driver of productivity—with models like the HC-G6053S and HC-G9055D built to match your exact workshop needs.

The Hidden Costs of Poor Long Material Storage

Long materials are bulky, awkward, and expensive to replace—and poor storage amplifies these risks. A steel service center in Ohio recently shared a common frustration: their team spent 25 minutes retrieving a single 6m steel pipe from a jumbled stack, often scratching adjacent pipes in the process. Over a year, those delays added up to 120 lost production hours, and damaged materials cost $19,000. A woodworking shop in Germany faced similar issues: 9m lumber beams stored horizontally consumed 40% of their floor space, leaving no room for new milling equipment.

These aren’t isolated problems. For any business handling long goods, inefficient storage means:

- Wasted floor space that could support production or inventory growth

- Extended retrieval times that delay orders and frustrate teams

- Material damage from improper stacking or handling

- Safety risks (e.g., falling beams, strained lifting) that lead to accidents

Herochu’s Storage Systems for Long Material eliminate these costs by designing around the unique demands of elongated items—whether you’re storing 3t steel tubes or 5t aluminum profiles.

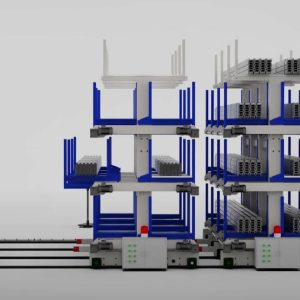

Meet the Herochu Lineup: Models Built for Your Load and Length Needs

Herochu offers four core models, each engineered to handle specific tube lengths, loads, and access requirements. No more forcing your materials to fit a generic rack—choose the system that aligns with what you store:

HC-G6053S & HC-G6053D: For 6m Long Materials

Ideal for workshops handling 6m pipes, rods, or profiles, these models support 3t per layer—enough for heavy carbon steel tubes or bundled aluminum extrusions. The HC-G6053S features a single-side power-assisted movement mode, perfect for facilities where access is only needed from one direction, while the HC-G6053D’s double-side design works for busy warehouses where teams retrieve materials from multiple angles. Both offer 4+1 layers and compartment dimensions (600×400mm, 600×600mm, 800×600mm) to fit everything from thin electrical conduit to thick structural beams. With an overall height of 3040mm (HC-G6053S) or 3840mm (HC-G6053D), they maximize vertical space without requiring excessive ceiling height.

HC-G9055S & HC-G9055D: For 9m Long Materials

For longer items like 9m lumber beams, steel I-beams, or plastic profiles, these models deliver the same reliability with extended length capacity. The HC-G9055S supports a robust 5t per layer—making it the go-to for ultra-heavy industrial materials—while the HC-G9055D offers 3t per layer with double-side access. Column spacing of 1500mm (vs. 1800mm on the 6m models) provides extra stability for longer loads, and the 330mm ground height ensures compatibility with forklifts and overhead cranes. A construction company in Texas uses the HC-G9055S to store 9m steel beams, cutting retrieval time from 20 minutes to 5 and eliminating beam warping from uneven stacking.

Beyond the Specs: Features That Transform Workflows

Herochu’s Storage Systems for Long Material aren’t just about holding weight—they’re about making your team’s job easier and your operations more efficient. Here’s how the details make a difference:

Power-Assisted Cantilever Movement: No More Struggling with Heavy Loads

The single or double-side power-assisted cantilever design lets teams pull out layers with minimal effort, even when loaded with 3t or 5t of material. Unlike static racks that require brute force or crane adjustments, Herochu’s system glides smoothly, reducing operator fatigue and cutting retrieval time by up to 70%. A metal fabricator in Pennsylvania reported a 25% boost in daily production after switching to the HC-G6053D—simply because their team spent less time wrestling with pipe bundles.

Customizable to the Last Detail

Every workshop is unique, and Herochu’s systems adapt to your needs—not the other way around. Beyond the standard models, we offer full customization:

- Load Capacity: Upgrade from 3t to 7t per layer for extra-heavy materials like thick steel pipes.

- Length: Extend beyond 9m for specialized items like 12m railway rails.

- Layers & Height: Add layers (up to 6+1) or adjust layer height to fit tall profiles.

- Operation: Choose manual for low-volume retrieval or electric for high-frequency access—ideal for busy logistics hubs.

A plastic processing facility in Italy needed to store 8m PVC pipes with a diameter of 800mm. We modified the HC-G6053D to include 800×800mm compartments and electric movement, letting their team retrieve pipes in seconds without damage.

Safety & Durability Backed by Certifications

Long materials pose unique safety risks—so Herochu builds protection into every system. Reinforced steel columns, anti-tip rails, and stable base frames prevent collapses, while the 330mm ground height ensures forklifts operate safely. All models are CE, EU, and ISO 9001 certified—meaning they meet strict global standards for material strength and manufacturing quality. For regulated industries like aerospace or oil and gas, these certifications aren’t just badges—they’re essential for passing audits and maintaining compliance.

Durability translates to long-term value, too. Herochu’s systems are built from high-gauge, corrosion-resistant steel with a powder-coated finish that repels oil, moisture, and workshop grime. Unlike generic racks that rust or warp after 2–3 years, our systems last 15+ years—delivering consistent performance without replacement costs.

Who Benefits from Herochu’s Long Material Storage Systems?

Our systems are designed for any industry that handles elongated items. We’ve helped:

- Metal & Steel Industry: A German steel mill used the HC-G9055S to store 9m stainless steel profiles, reducing scratch damage by 85%.

- Woodworking: A Canadian lumber yard deployed the HC-G6053D to organize 6m cedar beams, recovering 300 sq ft of floor space for a new cutting station.

- Construction: A U.S. contracting firm used customized HC-G9055D models to store 10m rebar, cutting on-site retrieval time by 60%.

- Plastic Processing: A French manufacturer stored 7m PVC pipes in modified HC-G6053S racks, eliminating moisture-related warping.

No matter your industry, if you’re tired of disorganized long materials slowing you down, Herochu has a solution.

Calculate the Value: Why $3,698 Is an Investment, Not a Cost

It’s easy to be tempted by generic long goods racks priced at

3,000. But these systems lack customization, durability, and safety features—and they end up costing more in the long run. A U.K. logistics company learned this: they bought

2,800genericracksfor6msteelpipes,onlytoreplacethem3yearslaterwhenthecantileversfailed.Thetotalcost?

5,600—plus $12,000 in damaged pipes from unstable storage.

Herochu’s systems, starting at $3,698, deliver ROI in 14–18 months through:

- 70% faster retrieval times (saving 10+ hours per week)

- 90% less material damage (cutting replacement costs by $15,000+ annually)

- 35% more floor space (enabling production growth without moving)

When you factor in 15+ years of use, Herochu’s system costs a fraction of generic alternatives per year.

Herochu: Your Partner in Long Material Storage

Storing long materials doesn’t have to be a headache. Herochu’s Storage Systems for Long Material combine technical precision, customization, and global certifications to protect your materials, save space, and boost efficiency. Whether you need the 6m HC-G6053D for double-side access or a fully customized 12m system for specialized profiles, we design around your workflow.

Our team doesn’t just sell you a rack—we conduct a deep dive into your material types, workshop layout, and future growth plans to create a solution that evolves with your business. We even provide installation support and maintenance tips to ensure your system performs at its best for years.

Don’t let disorganized long materials hold you back. Contact Herochu today to explore our HC-G6053 and HC-G9055 models, request a custom quote, or learn how we can transform your storage. Your long materials deserve the best—so does your business.

Choose Herochu. Choose efficiency.

You may get in touch with our backend technical staff first. Based on your specific parameters, we will formulate a suitable technical solution and provide a quotation. Alternatively, you can leave your contact details—such as WhatsApp, WeChat, or email address—and our professional sales team will reach out to you proactively.

You can share key information with us, including the type of items you plan to store on the shelves, the dimensions of those items, the quantity of shelves required, and any other specific details you have. With this information, we will develop a professional solution tailored to your needs. If you prefer, you can also leave your contact information, and our specialized team will contact you to address your questions.

To determine the right option, two key factors need to be considered first:

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

For a more accurate recommendation based on your specific needs, please leave your contact information, and we will provide targeted service.

Yes, we do. We can dispatch professional technicians to your factory to carry out on-site installation and debugging of the robotic arm, and we will continue working until the equipment completes a successful trial operation. Our team has provided such services in many countries, including South Africa, the United States, Russia, South Korea, Qatar, Egypt, Lebanon, and Mexico.

We have a comprehensive quality assurance system, supported by the following key measures:

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Our factory is located in Jinan, Shandong Province, China, specifically at No. 10 Industrial Park, Jiyang Street. It features a modern, standard workshop covering an area of 10,000 square meters.

We offer two convenient ways for you to assess our company’s capabilities:

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

We are Jinan Constant Storage Machinery Manufacturing Co., Ltd., a high-tech enterprise that integrates research and development, production, sales, installation, and after-sales service. Our core product range includes intelligent sheet metal material warehouses, drawer-type sheet metal shelves, telescopic cantilever shelves, servo swing arm manipulators, gantry loading and unloading manipulators, fully automatic loading and unloading systems, and heavy-duty sheet metal and pipe storage shelves. Equipped with a professional technical team and advanced production equipment, we are committed to providing high-quality, high-performance mechanical products and customized solutions to customers around the world.