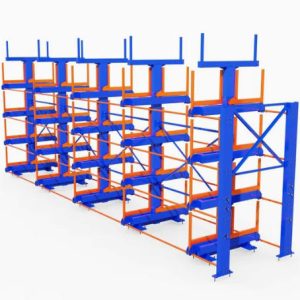

Herochu Telescopic Cantilever Shelves: Industrial-Grade Long Materials Storage for Custom Workshop Solutions

In today’s fast-paced manufacturing, warehousing, and construction environments, efficient storage of long, bulky materials—from steel pipes and metal sheets to timber and concrete profiles—isn’t just a convenience: it’s a critical driver of operational productivity, safety, and cost savings. Herochu, a leader in industrial storage solutions, introduces its Telescopic Cantilever Shelves: a purpose-built system engineered to solve the unique challenges of long materials storage, with customizable configurations tailored to your workshop’s exact needs, starting at $3,099. Backed by CE, UE, and ISO 9001 certifications, these shelves combine uncompromising durability, precision engineering, and user-centric design to transform how you store, access, and manage high-value long materials.

Why Herochu Telescopic Cantilever Shelves Stand Apart: Quality from the Source

Every Herochu Telescopic Cantilever Shelf begins with a commitment to raw material excellence—because a storage system is only as strong as its foundation. We source high-quality carbon steel exclusively from China’s leading large-scale steel groups, selected for their rigorous quality control standards and consistent material properties. This isn’t generic steel: it’s a premium-grade alloy chosen for its exceptional tensile strength, impact resistance, and long-term durability, ensuring your shelves withstand the heavy loads, frequent use, and harsh workshop conditions (including temperature fluctuations and moisture) that plague lesser systems. By partnering with trusted steel suppliers, we eliminate the risk of weak points or premature wear, guaranteeing a storage solution that protects your long materials investment for years.

The strength of Herochu’s shelves is further reinforced by our advanced welding process: dioxygen protection welding (also known as MIG welding). Unlike traditional arc welding, which leaves rough, porous joints prone to cracking or corrosion, dioxygen protection welding uses a continuous wire electrode and inert gas shield to create smooth, uniform welds. The result? Welding joints with superior cracking resistance, minimal deformation (even under heavy loads), and a clean, professional finish that requires no post-weld slag cleaning. This process isn’t just about aesthetics—it’s about structural integrity. Each weld is tested to ensure it meets ISO 9001 standards, so you can trust that every connection between columns, beams, and arms will hold steady, even when storing maximum-weight materials like thick-walled steel pipes or stacked metal sheets.

Precision Engineering: Every Component Designed for Accuracy

Industrial storage fails when components don’t fit—so Herochu leaves no room for error. Every column and beam in our Telescopic Cantilever Shelves is designed by a team of mechanical engineers with decades of experience in material handling, using software that simulates load distribution and stress points to optimize performance. These designs are then brought to life using professional cutting equipment (including CNC plasma cutters and laser cutters), ensuring each piece meets exact dimensional specifications. No more uneven gaps, misaligned arms, or ill-fitting parts: our precision cutting process guarantees that columns, beams, and brackets align perfectly during assembly, creating a stable structure that distributes weight evenly across the entire system.

This commitment to precision extends to even the smallest components, including the fixed arm connecting plates and column joints. We use laser cutting for these critical parts, a technology that delivers unmatched accuracy—controlling connection hole precision to within 0.15mm. Why does this matter? A tighter fit between connecting plates and columns means smaller assembly gaps, which directly reduces partial load deformation during use. When you store long, heavy materials (like 20-foot steel tubes) on the shelves, the system won’t bow, shift, or weaken at the joints—even if materials are loaded unevenly. This level of precision isn’t just a technical detail; it’s a promise that your shelves will maintain their structural integrity, protecting your materials from damage and your team from safety risks.

Durable Finishing: Wear-Resistant, Rust-Proof Protection for Longevity

Workshops are tough on equipment—dust, oil, moisture, and chemical exposure can quickly degrade even the strongest steel. That’s why Herochu subjects every Telescopic Cantilever Shelf to a 6-step professional spray treatment process designed to resist corrosion, scratches, and wear. The process begins with thorough oil removal (eliminating manufacturing residues that attract dust and moisture), followed by rust removal (using a phosphate-based solution to strip any surface oxidation), and a phosphating pre-treatment (which creates a porous layer that improves powder adhesion). Next, we apply a high-quality epoxy-polyester powder coating—chosen for its resistance to chipping, fading, and chemical damage—before curing the entire shelf in a high-temperature oven (at 180–200°C) to create a hard, uniform finish.

The result? A shelf that repels oil, resists rust, and stands up to daily impacts from material handling equipment (like forklifts or pallet jacks). Unlike painted shelves that chip easily, Herochu’s powder-coated finish maintains its integrity for years, even in humid warehouses or workshops with exposure to industrial chemicals. This means less maintenance, fewer replacements, and a storage system that looks and performs like new, even after years of heavy use.

Two Operation Modes: Hand-Cranked and Electric for Every Workshop Need

Herochu understands that no two workshops are the same—so we offer two telescopic operation modes to match your workflow, budget, and material handling volume: hand-cranked and electric.

Hand-Cranked Telescopic Cantilever Shelves: Simple, Reliable, Low-Maintenance

For workshops with moderate storage needs or limited power access, our hand-cranked model delivers effortless operation without compromising performance. We’ve engineered the system using a combination of gear transmission and sprocket transmission, with a carefully calibrated speed ratio that minimizes manual effort. The key innovation? A rotating crank designed to reduce hand-cranked shear stress to less than 120N—roughly the force of lifting a 12kg object. This means even a single worker can extend or retract the cantilever arms with ease, no matter how heavy the stored materials (up to the shelf’s maximum load capacity).

The hand-cranked system requires no electricity, making it ideal for outdoor storage areas, temporary workshops, or facilities where power conservation is a priority. It’s also low-maintenance: with fewer moving parts than electric models, there’s less risk of mechanical failure, and routine checks (like lubricating gears) take minutes to complete.

Electric Telescopic Cantilever Shelves: Automated Efficiency for High-Volume Operations

For warehouses or workshops that handle large quantities of long materials (or require frequent access to stored items), our electric model transforms material handling into a fast, automated process. We’ve equipped each electric shelf with a variable frequency reduction motor paired with a high-quality frequency converter, which allows for smooth, adjustable speed control—preventing sudden jolts that could damage materials or the shelf itself. The system is also fitted with a touch screen control module, giving operators intuitive access to semi-automatic or fully automatic storage and retrieval functions.

With the electric model, you can program arm extensions, set load limits, and even integrate the shelf with your workshop’s inventory management system (via optional IoT connectivity). This automation cuts down on manual labor time: retrieving a 30-foot steel tube that once took two workers and a forklift can now be done in seconds with the push of a button. It also reduces human error—no more overloading arms or misaligning materials—improving both efficiency and safety.

Safety First: Stable, Secure Storage for Peace of Mind

Herochu’s Telescopic Cantilever Shelves are engineered to meet the strictest industrial safety standards—because storing heavy, long materials should never put your team at risk. Here’s how we prioritize safety:

- Double-Bearing Movable Arms: The movable cantilever arms are supported by double bearings, which distribute weight across a larger surface area. This design reduces deformation under load (even when storing maximum-weight materials) and lowers resistance during arm extension/retraction—preventing sudden jolts or 卡住 (jamming) that could cause accidents.

- Robot-Welded Fixed Arm End Plates: Unlike cheaper shelves that use screw connections (which can loosen or shift under stress), our fixed arm end plates are welded using industrial robots. Robot welding ensures consistent, high-strength joints that won’t fail due to screw displacement. Every weld is inspected to meet CE and ISO 9001 standards, so you can trust that arms will stay securely attached to columns.

- Adjustable Foot Pads: Uneven workshop floors are a common cause of shelf instability—but Herochu solves this with special, thickened foot pads (available in multiple thicknesses) for each shelf leg. These pads can be adjusted to level the entire system, even on sloped or uneven surfaces, preventing tipping or wobbling.

The Rise of Telescopic Cantilever Racks: Why Industry Leaders Are Making the Switch

Traditional static racks for long materials have long been a pain point for workshops: they waste space (requiring wide aisles for access), limit flexibility (can’t accommodate different material lengths), and make retrieval time-consuming. That’s why telescopic cantilever racks—like Herochu’s—are rapidly becoming the standard for industries handling steel tubes, metal sheets, timber, and other long materials.

A recent study by a leading global industry research firm found that the global market for long materials storage systems is growing at a 7.2% annual rate, driven by the rise of lean manufacturing and warehouse space optimization. Within this market, telescopic cantilever racks are the fastest-growing segment—thanks to their ability to maximize storage density and streamline material handling. Industry experts agree: “Telescopic cantilever racks don’t just store materials—they transform workflow,” says John Miller, a warehouse operations consultant with 20 years of experience. “Our clients report cutting material retrieval time by 40% and increasing storage capacity by 30% after switching to Herochu’s system.”

The benefits of this shift are clear:

- Optimized Space Utilization: Herochu’s telescopic design lets you store materials closer together (since arms extend only when needed) and use vertical space more effectively. This reduces floor space requirements by up to 35% compared to static racks—freeing up room for other equipment or expansion.

- Customizable Configurations: Whether you need to store 10-foot metal sheets or 40-foot steel pipes, Herochu’s shelves can be customized. We offer adjustable arm lengths, variable column heights, and optional add-ons (like side guards or label holders) to match your exact needs.

- Easy Access: The telescopic arms extend outward, bringing materials to your team—no more reaching over or under stored items. This reduces the risk of material damage (from accidental impacts) and worker injuries (from lifting or stretching).

Customize Your Herochu Telescopic Cantilever Shelf: Built for Your Workshop

Every workshop has unique storage needs—and Herochu doesn’t believe in one-size-fits-all solutions. Our team of storage experts works with you to design a Telescopic Cantilever Shelf system that fits your space, materials, and workflow. Here’s how the customization process works:

- Needs Assessment: We start by understanding your storage goals—what materials you’re storing (weight, length, volume), how often you need to access them, and your workshop’s space constraints.

- Design Proposal: Our engineers create a 3D model of your custom shelf system, including arm lengths, column heights, operation mode (hand-cranked/electric), and safety features.

- Review and Adjustments: We present the design to you for feedback, making adjustments until it perfectly matches your needs.

- Manufacturing and Installation: Once approved, we manufacture your shelf using our precision processes, then deliver and install it (with optional professional installation services) to ensure it’s level, stable, and ready to use.

All custom systems start at $3,099—an investment that pays for itself in reduced labor costs, fewer material damages, and maximized storage space.

Why Choose Herochu? More Than a Shelf—A Partner in Productivity

Herochu has been designing industrial storage solutions for over a decade, serving clients in manufacturing, construction, oil and gas, and logistics. Our Telescopic Cantilever Shelves aren’t just products—they’re a commitment to helping you work smarter, safer, and more efficiently. With CE, UE, and ISO 9001 certifications, we guarantee that every shelf meets global quality standards. We also offer a 5-year warranty on all structural components (and 2-year warranty on electric parts), plus ongoing maintenance support to keep your system running smoothly.

In a world where workshop efficiency directly impacts your bottom line, Herochu’s Telescopic Cantilever Shelves are the solution you’ve been looking for. They’re not just shelves—they’re a tool to help you store better, work faster, and grow your business.

Ready to transform your long materials storage? Contact Herochu today to schedule a free needs assessment and get a custom quote for your workshop.

You may get in touch with our backend technical staff first. Based on your specific parameters, we will formulate a suitable technical solution and provide a quotation. Alternatively, you can leave your contact details—such as WhatsApp, WeChat, or email address—and our professional sales team will reach out to you proactively.

You can share key information with us, including the type of items you plan to store on the shelves, the dimensions of those items, the quantity of shelves required, and any other specific details you have. With this information, we will develop a professional solution tailored to your needs. If you prefer, you can also leave your contact information, and our specialized team will contact you to address your questions.

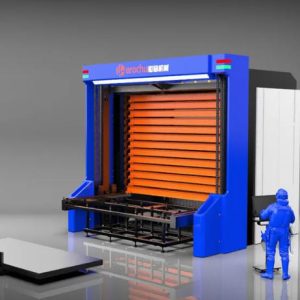

To determine the right option, two key factors need to be considered first:

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

For a more accurate recommendation based on your specific needs, please leave your contact information, and we will provide targeted service.

Yes, we do. We can dispatch professional technicians to your factory to carry out on-site installation and debugging of the robotic arm, and we will continue working until the equipment completes a successful trial operation. Our team has provided such services in many countries, including South Africa, the United States, Russia, South Korea, Qatar, Egypt, Lebanon, and Mexico.

We have a comprehensive quality assurance system, supported by the following key measures:

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Our factory is located in Jinan, Shandong Province, China, specifically at No. 10 Industrial Park, Jiyang Street. It features a modern, standard workshop covering an area of 10,000 square meters.

We offer two convenient ways for you to assess our company’s capabilities:

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

We are Jinan Constant Storage Machinery Manufacturing Co., Ltd., a high-tech enterprise that integrates research and development, production, sales, installation, and after-sales service. Our core product range includes intelligent sheet metal material warehouses, drawer-type sheet metal shelves, telescopic cantilever shelves, servo swing arm manipulators, gantry loading and unloading manipulators, fully automatic loading and unloading systems, and heavy-duty sheet metal and pipe storage shelves. Equipped with a professional technical team and advanced production equipment, we are committed to providing high-quality, high-performance mechanical products and customized solutions to customers around the world.