The Sheet Steel Rack Solution for Optimized Warehouse Storage

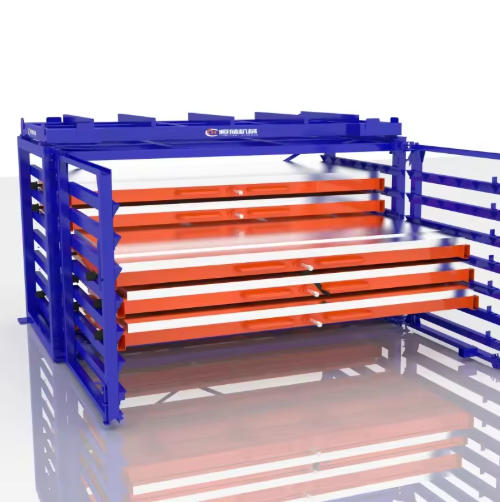

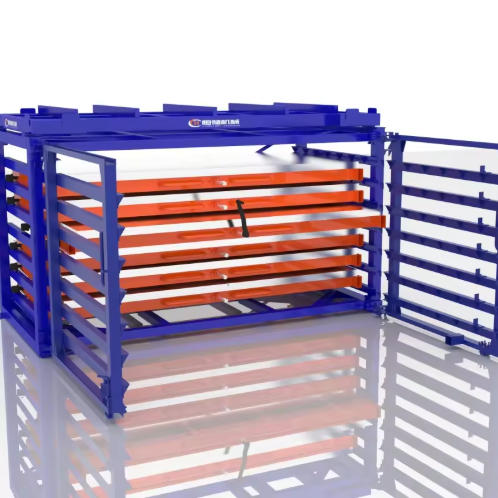

The Herochu Sheet Steel Rack Solution for Optimized Warehouse Storage is engineered to fix these pain points, turning disorganized, underutilized spaces into streamlined, high-capacity storage hubs. Certified to meet global quality standards (CE, EU, ISO 9001), fully customizable to your workshop’s unique layout, and starting at just $2,980, this rack system isn’t just a storage tool—it’s a strategic investment in long-term warehouse performance.

|

Standard

|

HC-B2015-62

|

HB-B3015-65

|

HB-B6015-63

|

HC-B6020-65

|

|

Plate size /mm

|

2000x150mm

|

3000×1500

|

6000×1500

|

6000×2000

|

For businesses undergoing warehouse renovation or struggling with inefficient bulk material storage—whether you’re managing metal sheets, wood boards, or building supplies—space waste, slow access, and damaged inventory can derail operational efficiency and inflate costs. The Herochu Sheet Steel Rack Solution for Optimized Warehouse Storage is engineered to fix these pain points, turning disorganized, underutilized spaces into streamlined, high-capacity storage hubs. Certified to meet global quality standards (CE, EU, ISO 9001), fully customizable to your workshop’s unique layout, and starting at just $2,980, this rack system isn’t just a storage tool—it’s a strategic investment in long-term warehouse performance.

Why Warehouse Renovation Needs the Right Sheet Steel Rack

Warehouse renovation is about more than fresh paint or new flooring—it’s about reimagining how space works for your team. Many businesses approach renovation with the goal of “more storage,” only to repeat old mistakes with ill-suited racking: traditional vertical stacks leave gaps between uneven materials, manual handling leads to scratched or bent sheets, and retrieving inventory means moving entire piles—wasting time and labor. A Florida-based construction company’s warehouse manager knows this all too well: “We always felt like we were running out of space. Our sheets were piled so high that it was difficult to find what we needed, and materials were frequently damaged in the process.”

Herochu’s Sheet Steel Rack Solution changes this. Designed specifically for optimized storage during and after renovation, it addresses the three biggest pain points of bulk material management:

1. Wasted Space: Turn Empty Gaps into Usable Storage

Traditional racking fails to adapt to materials of different sizes and shapes, creating dead zones that eat up valuable square footage. Herochu’s horizontal-focused design eliminates these gaps by storing sheets side-by-side in a layered system, maximizing every inch of available space. A Texas-based metal processing plant saw immediate results after integrating the racks into their renovation: “After introducing these racks, our warehouse space utilization increased by 30%. Storing sheets horizontally means we can fit more material and avoid the wasted space from high stacking.” For businesses facing space constraints, this translates to delayed expansion costs and room to grow without relocating.

2. Inconvenient Access: Retrieve Materials in Seconds, Not Minutes

Renovation should make workflows faster, not slower. Traditional vertical stacks force teams to move multiple sheets just to reach the one they need—risking damage and eating into productivity. Herochu’s Sheet Steel Rack uses a intuitive layered structure where every sheet is visible and accessible without shifting other inventory. Whether you’re grabbing a single metal plate for a small order or a stack of wood boards for a large project, no more rearranging piles. This cuts retrieval time by up to 50%, reduces labor strain, and keeps orders moving on schedule.

3. Low Storage Efficiency: End Chaos with Organized Layouts

A disorganized storage area turns even simple tasks—like locating a specific sheet size—into time-consuming hunts. Herochu’s rack system brings structure to warehouse renovation by creating designated spots for every material. Label layers by type, size, or project, and even new team members can find what they need in seconds. No more misplaced inventory, no more missed deadlines, and no more frustration from sifting through cluttered stacks.

The Advantages That Make Herochu’s Sheet Steel Rack a Renovation Must-Have

Warehouse renovation is an opportunity to future-proof your operations—and Herochu’s Sheet Steel Rack is built to grow with you. Its design prioritizes flexibility, durability, and cost savings, offering four key benefits that go beyond basic storage:

1. Flexibility to Fit Any Material or Space

No two warehouses store the same items—your rack system shouldn’t treat them as such. Herochu’s modular design adapts to materials of all sizes (from small metal panels to large building boards), weights (lightweight aluminum to heavy steel sheets), and shapes. Need to adjust the rack to fit a narrow corner of your renovated warehouse? Add extra layers as your inventory grows? Modify the structure to handle specialized materials? Our team tailors the rack to your needs, ensuring it fits seamlessly into your new layout.

2. Durability That Protects Your Inventory (and Your Budget)

Damaged materials are a hidden cost of poor storage—scratched metal sheets, bent wood boards, or deformed panels mean wasted money and delayed orders. Herochu’s Sheet Steel Rack eliminates this risk with a heavy-duty steel construction that supports bulk loads without strain, and smooth, stable surfaces that minimize friction between sheets. A Georgia-based building supplier’s manager noticed the difference immediately: “By storing sheets in horizontal racks, we no longer worry about damage from over-stacking or improper handling. Our metal plates, in particular, are kept in pristine condition.” This reduces replacement costs, improves customer satisfaction, and preserves the value of your inventory.

3. Compliance You Can Trust

Warehouse renovation often requires meeting safety and quality standards—and Herochu’s Sheet Steel Rack takes the guesswork out of compliance. It’s certified to CE, EU, and ISO 9001 standards, meaning it meets rigorous global requirements for strength, stability, and safety. Whether you’re renovating a small workshop or a large distribution center, you can trust the rack to perform reliably in high-traffic environments, protecting your team and your materials.

4. Affordability That Aligns with Renovation Budgets

Renovation costs add up quickly—but investing in optimized storage shouldn’t break the bank. Herochu’s Sheet Steel Rack starts at just $2,980, making it an accessible solution for businesses of all sizes. Its long lifespan (thanks to durable steel construction) and low maintenance needs mean it delivers ROI for years, offsetting initial costs with reduced waste, faster workflows, and lower labor expenses.

Customization: Build a Rack That Fits Your Renovated Warehouse

Herochu knows “one-size-fits-all” doesn’t work for warehouse renovation. That’s why every Sheet Steel Rack is fully customizable, with options to match your space, inventory, and workflow:

- Size Adjustments: Modify length, width, and height to fit tight corners, high ceilings, or irregularly shaped areas of your renovated warehouse.

- Layer Configuration: Choose 2–8+ layers based on your storage volume—add more as your business grows.

- Weight Capacity Upgrades: Standard models support common sheet metal weights, with options to handle extra-heavy materials (up to 5T per layer) for industrial use.

- Accessories for Added Functionality: Add compartment dividers to separate material types, label holders for easy identification, or non-slip surfaces to protect delicate sheets.

Our team works with you to assess your renovated space, inventory needs, and workflow goals—ensuring the rack doesn’t just fit your warehouse, but enhances how your team works.

Why Herochu Is the Right Choice for Your Warehouse Renovation

Warehouse renovation is about creating a space that works harder for you—and the Herochu Sheet Steel Rack Solution for Optimized Warehouse Storage does exactly that. It turns wasted space into usable storage, slow retrieval into fast access, and chaotic piles into organized inventory. Whether you’re renovating to expand capacity, improve efficiency, or meet compliance standards, this rack system is a critical piece of the puzzle.

Don’t let poor storage undermine your renovation goals. Contact Herochu today to discuss your custom Sheet Steel Rack. Our team will help you design a solution that fits your space, your budget, and your vision—so your renovated warehouse isn’t just new, but better.

Q1: What steps should I take to start the procurement process?

You may get in touch with our backend technical staff first. Based on your specific parameters, we will formulate a suitable technical solution and provide a quotation. Alternatively, you can leave your contact details—such as WhatsApp, WeChat, or email address—and our professional sales team will reach out to you proactively.

Q2: How can I inform you of my need for suitable shelves?

You can share key information with us, including the type of items you plan to store on the shelves, the dimensions of those items, the quantity of shelves required, and any other specific details you have. With this information, we will develop a professional solution tailored to your needs. If you prefer, you can also leave your contact information, and our specialized team will contact you to address your questions.

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

To determine the right option, two key factors need to be considered first:

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

For a more accurate recommendation based on your specific needs, please leave your contact information, and we will provide targeted service.

Q4: Do you offer on-site installation and debugging services?

Yes, we do. We can dispatch professional technicians to your factory to carry out on-site installation and debugging of the robotic arm, and we will continue working until the equipment completes a successful trial operation. Our team has provided such services in many countries, including South Africa, the United States, Russia, South Korea, Qatar, Egypt, Lebanon, and Mexico.

Q5: What measures do you take to ensure product quality?

We have a comprehensive quality assurance system, supported by the following key measures:

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Our factory is located in Jinan, Shandong Province, China, specifically at No. 10 Industrial Park, Jiyang Street. It features a modern, standard workshop covering an area of 10,000 square meters.

Q7: How can I verify your company’s strength?

We offer two convenient ways for you to assess our company’s capabilities:

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

We are Jinan Constant Storage Machinery Manufacturing Co., Ltd., a high-tech enterprise that integrates research and development, production, sales, installation, and after-sales service. Our core product range includes intelligent sheet metal material warehouses, drawer-type sheet metal shelves, telescopic cantilever shelves, servo swing arm manipulators, gantry loading and unloading manipulators, fully automatic loading and unloading systems, and heavy-duty sheet metal and pipe storage shelves. Equipped with a professional technical team and advanced production equipment, we are committed to providing high-quality, high-performance mechanical products and customized solutions to customers around the world.

PRODUCTS

-

Sheet Metal Storage Racks

High-Capacity Vertical Sheet Racks for Organized Storage Needs

Read moreRated 0 out of 5 -

Sheet Metal Storage Racks

Heavy-Duty Vertical Roll-out Sheet Racks for Steel Scrap

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Automatic Sheet Metal Storage Systems for Fiber Laser Cutters

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Automatic sheet metal storage tower for Fiber Laser cutting

Read moreRated 0 out of 5 -

Sheet Metal Storage Racks

The Sheet Steel Rack Solution for Optimized Warehouse Storage

Read moreRated 0 out of 5 -

Sheet Metal Storage Racks

Maximize Warehouse Space: A Guide to Sheet Steel Storage Racks

Read moreRated 0 out of 5 -

Automated Sheet Metal Storage Systems

Automatic Storage System for Long Material

Read moreRated 0 out of 5 -

Sheet Metal Storage Racks

Heavy Duty Sheet Metal Storage Racks of Warehouse

Read moreRated 0 out of 5