Vertical storage racks for sheet metal

The Herochu vertical storage system is conceived around the principle of maximizing vertical space, an often-underutilized asset in industrial settings. By storing sheets vertically, these racks liberate substantial floor area that can be reallocated to production machinery, assembly operations, or other value-generating activities. This approach transforms a disorganized storage zone into a clean, orderly, and highly functional environment. The system’s suitability extends across a diverse range of materials, including small sheets, scattered scraps, large leftovers, and semi-finished parts, making it an indispensable asset for job shops and high-volume manufacturers alike.

Herochu Vertical Storage Racks: The Engineered Solution for Organized and Safe Sheet Metal Handling

Efficient management of sheet metal inventory remains a persistent challenge for workshops and manufacturing facilities worldwide. The difficulties of storing off-cuts, semi-finished components, and sheets of varying sizes often lead to cluttered workspaces, inefficient material retrieval, and significant safety hazards for personnel. Traditional horizontal storage solutions consume a premium of valuable floor space and frequently result in damaged materials through improper handling or stacking. Herochu addresses these critical operational inefficiencies with our precision-engineered series of Vertical Storage Racks for sheet metal, a system designed to revolutionize material organization, enhance workplace safety, and optimize your workshop’s spatial economy.

The Herochu vertical storage system is conceived around the principle of maximizing vertical space, an often-underutilized asset in industrial settings. By storing sheets vertically, these racks liberate substantial floor area that can be reallocated to production machinery, assembly operations, or other value-generating activities. This approach transforms a disorganized storage zone into a clean, orderly, and highly functional environment. The system’s suitability extends across a diverse range of materials, including small sheets, scattered scraps, large leftovers, and semi-finished parts, making it an indispensable asset for job shops and high-volume manufacturers alike.

A cornerstone feature of the Herochu design is the fully roll-out sliding unit. Each independent carriage can be smoothly extended to 100% of its depth, providing complete and unobstructed access to the stored sheets. This eliminates the dangerous and time-consuming practice of manually rifling through a stack of metal to retrieve a specific piece. Operators can quickly overview the entire inventory, select the required material with ease, and return the unit to its closed position in a single, fluid motion. This process not only saves considerable time and labor but also drastically reduces the physical strain on employees, as the system can be operated effortlessly by a single person.

Safety and material protection are paramount in the design philosophy. Each roll-out unit is engineered with a precise 3-degree backward slant. This subtle but critical angle actively prevents sheets from slipping forward during the retrieval process, securing the load and protecting both the valuable metal material and the operator from potential injury. Furthermore, the structured nature of vertical storage removes the risk of unsteady stacks collapsing, creating a fundamentally safer workshop environment. The robust construction of each unit, with a load capacity of up to 700 kg, ensures that even heavy materials are handled with confidence and stability.

Herochu understands that no two workshops are identical. Therefore, our vertical racks offer exceptional configuration flexibility. They can be custom-designed for either “front-back” roll-out movement or “left-right” lateral movement, allowing for seamless integration into your existing floor plan and workflow. This adaptability ensures that the storage solution works in harmony with your production process, rather than forcing an inefficient compromise.

As a CE and ISO 9001 certified manufacturer, Herochu is unwaveringly committed to the highest international standards of quality, safety, and performance. Our dedication to excellence is reflected in every product we engineer. We offer a range of standard models, including the HC-V2010-15 for 2000x1000mm sheets, the HC-F2513-15 for 2500x1500mm sheets, and the HC-F3015-122 for 3000x1500mm sheets, each featuring 15 layers for high-density storage. Beyond these standards, we provide extensive customization options to meet unique spatial and operational requirements, ensuring a perfect fit for your specific application.

Investing in a Herochu Vertical Storage System is an investment in enhanced productivity, superior organization, and demonstrable workplace safety. It represents a decisive move away from outdated and hazardous storage practices, delivering a rapid return on investment through streamlined operations, reduced material damage, and optimized use of valuable real estate.

Discover the Herochu advantage. Contact our storage solutions team today for a personalized consultation and to receive a detailed quotation. Customizable vertical storage solutions for your workshop begin at $3,660.

Brand: Herochu

Model Numbers: HC-V2010-15, HC-F2513-15, HC-F3015-122

Product Name: Vertical Sheet Metal Storage Rack

Certification: CE, ISO 9001

Key Feature: 100% Roll-Out Sliding Units, 3-Degree Safety Tilt

Capacity: Up to 700 kg per unit

Function: High-Density Vertical Storage for Sheet Metal Off-Cuts and Parts

Application: Manufacturing Workshops, Metal Fabrication, Job Shops

Q1: What steps should I take to start the procurement process?

Q2: How can I inform you of my need for suitable shelves?

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

Q4: Do you offer on-site installation and debugging services?

Q5: What measures do you take to ensure product quality?

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Q7: How can I verify your company’s strength?

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

PRODUCTS

-

Fiber Laser Automation Systems

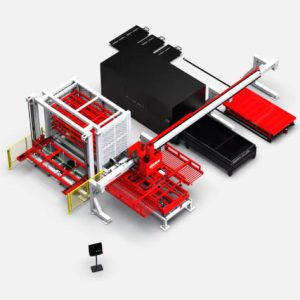

Automation loading and unloading systems for Laser Processing Machines

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Fiber Laser Automation | Automatic Loading And Unloading

Read moreRated 0 out of 5 -

Sheet Metal Material Handling Equipment

Loading & Unloading Equipment Servo swing arm handling manipulator

Read moreRated 0 out of 5 -

Sheet Metal Material Handling Equipment

Advanced Sheet Metal Palletizing Robot for Efficient Automation Solutions

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Heavy Duty Roll Out Cantilever Pipe Storage Racks

Read moreRated 0 out of 5 -

Sheet Metal Material Handling Equipment

Laser Loading and Unloading Systems Suction Crane Vacuum Lifter for Sheet Metal

Read moreRated 0 out of 5 -

Sheet Metal Material Handling Equipment

Pneumatic Cantilever Manipulator Vacuum Lifter Crane

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Automatic Pipe Storage Racks Automated Profile Storage Warehouse Systems

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Roll Out Cantilever Pipe Storage Rack

Read moreRated 0 out of 5