Herochu Professional Sheet Metal Storage Rack Systems

Engineered for Maximum Space Efficiency and Material Protection

Revolutionizing Industrial Storage with Smart Rack Design

Herochu sheet metal storage racks represent the pinnacle of workshop organization technology, combining German-engineered durability with customizable configurations for diverse industrial applications. Our CE/EU/ISO 9001-certified systems solve three critical challenges facing metal fabrication shops today: floor space optimization, material handling efficiency, and inventory protection.

Core Technology & Structural Advantages

- Space Transformation: Converts vertical dead space into active storage, reclaiming 50-70% of floor area compared to traditional stacking

- Load Mastery: Military-grade steel frames support up to 5,500 lbs per shelf with reinforced weld points

- Access Revolution: Ergonomic roll-out mechanisms reduce retrieval time by 80% compared to conventional shelving

- Damage Prevention: Powder-coated steel side rails eliminate edge deformation during extension/retraction cycles

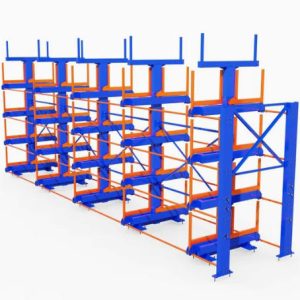

Horizontal Roll-Out Series: The Workshop Workhorse

Our flagship horizontal system features patent-pending T-track guidance technology that maintains perfect shelf alignment even at maximum extension. The 12-gauge steel construction withstands daily industrial abuse while the optional anti-vibration coating prevents material slippage.

Technical Specifications

| Parameter | Specification |

|---|---|

| Frame Material | ASTM A36 Structural Steel |

| Surface Finish | Electrostatic Powder Coating (60μm) |

| Standard Height | 84″ (7ft) with 6″ adjustability |

| Load Capacity | 5,500 lbs/shelf (2,500kg) |

Unique Value Propositions

- Dual-Axis Stabilization: Cross-braced framework prevents torsion during seismic events

- Smart Lock System: Automated shelf engagement when retracted (optional RFID version available)

- Modular Expansion: Add unlimited units in linear configuration without structural compromise

Forklift Stacker Configuration: High-Density Solution

Designed for operations handling 20+ sheets daily, our stacker series incorporates:

- Pallet-Style Shelving: Removable decks with 4-way forklift access

- Dynamic Load Distribution: Stress-dispersing base plates prevent concrete floor damage

- Visual Management: Color-coded shelf edges for instant thickness identification

Performance Metrics

- 19-shelf configuration stores 228 standard 4’x8′ sheets in 40 sq.ft footprint

- 8-second average retrieval time with trained operator

- 0.003″ tolerance in shelf alignment for precision manufacturing environments

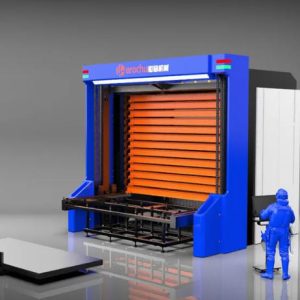

Vertical Lift Towers: The Space-Saving Marvel

For facilities with extreme space constraints, our vertical systems deliver:

- Z-Axis Optimization: 25-shelf towers reach 28′ height with just 6’x6′ base

- Vacuum-Compatible: Integrated ports for automated material handling systems

- Climate Control: Optional HVAC ducting for sensitive alloys

Industrial Certification Package

- CE Machinery Directive 2006/42/EC

- ISO 9001:2015 Quality Management

- EN 1090-1 Execution Class 2

- RoHS 3 Compliant Components

Custom Engineering Services

Herochu provides complimentary workshop layout analysis including:

- 3D Space Modeling: CAD simulations of proposed installations

- Load Analysis: Structural calculations for your specific material mix

- Flow Optimization: Throughput analysis to minimize handling steps

Popular Customizations

- Laser-cut numbering systems for ISO 9001 compliance

- EMI-shielded versions for electronics manufacturing

- Food-grade stainless steel construction (316L)

- Explosion-proof configurations for hazardous environments

Why Global Manufacturers Choose Herochu

- 10-Year Structural Warranty: Industry’s most comprehensive coverage

- Just-in-Time Delivery: 98.7% on-time completion rate

- Installation Certification: All installers are AWS-certified welders

Base configuration starts at $3,099 with 6-8 week lead time. Contact our engineering team for custom quotations.