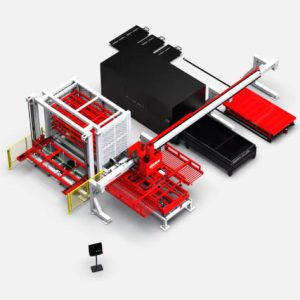

Herochu Sheet Metal Vacuum Lifting Equipment – 600 kg of Grip, 4 Bar of Air, Zero Deflection

Move 3 m × 1.5 m steel, stainless, aluminium or copper sheet off a laser, onto a press-brake and into the stillage without ever touching it with gloves. Herochu’s lowered-frame vacuum lifter does exactly that, using nothing more than 600 W of compressed air and eight spring-loaded suction cups that adapt to the natural bow of thin gauge material. The result is a 1,850 mm vertical stroke, 3,000 mm horizontal reach and a repeat cycle that keeps pace with modern 6 kW fiber lasers—at a workshop price that starts at $3,698.

Built for tight bays, low ceilings and fast takt times

Headroom is expensive; downtime is worse. The main cross-beam is only 415 mm high, so the lifter slips under conveyors, mezzanines and crane bridges that would stop taller frames. Inside that compact beam is a 6 l vacuum reservoir charged to –0.75 bar. The reservoir acts as both structural spine and buffer tank, eliminating the separate cylinder competitors bolt on as an afterthought. Weight drops to 20 kg for the complete head, so a 250 kg jib crane can still lift the full 600 kg payload without approaching its limit.

Eight cups, four arms, infinite positions

Each 200 mm cup is mounted on a 12 mm zinc-plated arm that slides the full 2,500 mm span of the beam. Thumb-screw clamps lock the arms in seconds, letting the operator switch from a narrow 500 mm strip to a full 3 m architectural panel without tools. Cups are vulcanised oil-resistant rubber, 60° Shore for polished sheets, 30° Shore for textured or oiled stock. A 20 mm compression spring inside every cup compensates for up to 15 mm deflection, so even 0.5 mm thin aluminium lifts flat and stays flat until it is placed.

Air only, yet failsafe

The venturi cartridge generates 180 m³/h of vacuum at 4 bar shop air. If the compressor trips, a non-return valve and the integral reservoir hold the load for a minimum of five minutes—long enough to set it down or summon help. An audible 90 dB alarm and flashing red beacon trigger at –0.45 bar, well above the safety margin. A colour-coded gauge gives the operator continuous feedback: green for safe, amber for caution, red for immediate action. A sintered brass filter protects the cartridge from grinding dust and condensation; the filter pops out for cleaning without breaking the vacuum circuit.

One lever, two motions

A single slide valve on the handle selects “suction” or “release”. There is no electrical wiring to fail, no battery to forget, no PLC to reboot. The valve is deliberately oversized, so even moist or slightly porous plate still seals. Because release is gradual, the sheet settles rather than drops, protecting the next sheet in the stack from edge impact. Operators report a 35 % reduction in dented corners after the first month of use.

CE/UE/ISO 9001 pedigree

Every lifter is built in Shandong, China, under an ISO 9001 line that also supplies European wind-tower fabricators. Steel components are shot-blasted SA 2.5 and finished with two-part polyurethane RAL 5010. Hoses meet EN ISO 5774; non-return valves are tested to 10,000 cycles; the complete head is proof-loaded to 2 × WLL before shipment. Documentation includes CE declaration, test certificate and material traceability for the beam and cups.

Real numbers that fit real machines

- Liftable format: 3,000 mm × 1,500 mm

- Max. capacity: 600 kg

- Vertical travel: 1,850 mm (hook to cup face)

- Horizontal travel: 3,000 mm under a 4 m jib

- Overall frame: 3,800 mm × 1,700 mm × 1,700 mm

- Compressed-air demand: 250 Nl/min at 4–6 bar

- Sound level: <68 dB(A) at 1 m

Packaging that respects your receiving dock

One single item, one plywood crate, 300 cm × 100 cm × 300 cm, 20 kg net. A forklift can unload it; two technicians can have it bolted to an existing jib before lunch. No special rigging, no third-party calibration, no hidden transport surcharges.

Twelve-month warranty, lifetime sense of security

The beam, cups, valve and gauge are covered for one full year, but the design is straightforward enough that most customers keep the same unit for a decade, replacing only cups every 18–24 months. Spare parts ship from stock in Rotterdam and Chicago; a QR code on the beam links to exploded drawings and overnight order forms.

Typical payback curve

A 4 kW laser cutting 8 mm mild steel produces roughly 25 sheets per hour. Manual double-handling adds 45 seconds per sheet; the Herochu lifter cuts that to 12 seconds. At €60/hr machine rate, the saving is €0.44 per sheet. Run two shifts, five days, 48 weeks and the lifter pays for itself in 14 weeks—then keeps saving €22,000 every year.

Who is already using it

- Architectural cladding shops moving pre-painted aluminium

- Stainless tank builders feeding 1 mm to 12 mm plate into plasma beds

- HVAC contractors stacking galvanized duct segments

- Sign-makers positioning 5 m composite faces onto mounting rails

- Job-shop fabricators loading 5-axis press brakes overnight without a second operator

How to order

- Email the largest sheet size, weight and your jib radius.

- Receive a 2D drawing and firm price within six hours.

- Approve → 7-day build → 48-hour air test → DAP delivery to your door.

Stop measuring productivity in bruised forearms and dented edges. Equip your crane with Herochu sheet metal vacuum lifting equipment and let eight cups do the gripping while the operator guides the next job into the laser. One hand on the valve, one eye on the gauge, zero drama on the floor—that is what 600 kg of controlled vacuum feels like.