The Definitive Guide to Calculating ROI for Your Cantilever Rack System Investment

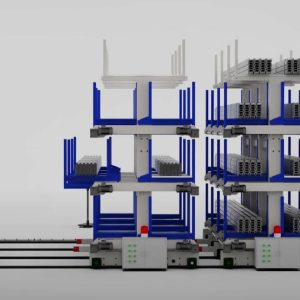

Every warehouse manager knows the frustration: valuable time wasted searching for materials, preventable damage to inventory, and inefficient use of expensive floor space. While the operational benefits of cantilever racking systems are immediately apparent to those working with these challenges daily, the financial decision-makers often see only the initial investment required. The critical task becomes translating these operational improvements into the language of business: return on investment, payback periods, and bottom-line impact. This comprehensive analysis provides a structured framework for evaluating the true financial implications of implementing a Herochu Cantilever Rack System, transforming what appears as a capital expenditure into a demonstrably profitable investment in operational excellence.

The financial justification for cantilever racking begins with understanding the hidden costs of inadequate storage solutions. Traditional storage methods for long, bulky, or irregular items—including floor stacking, basic shelving, or makeshift solutions—create numerous indirect expenses that accumulate silently but significantly over time. These costs manifest through inefficient labor utilization, wasted facility space, inventory damage, and missed business opportunities. By systematically quantifying these often-overlooked expenses, operations managers can build a compelling financial case that demonstrates how a properly engineered storage solution doesn’t merely store materials—it generates measurable financial returns through improved efficiency and reduced waste.

Quantifying Current Storage Costs: The Foundation of ROI Calculation

The first step in building your financial justification involves conducting a thorough audit of current storage-related expenses. This process requires examining operational data from the previous twelve months to establish baseline performance metrics. Labor costs represent perhaps the most significant and easily quantifiable expense category. Calculate the average time employees spend searching for materials, moving items to access others, or reorganizing storage areas to accommodate new inventory. Multiply these hours by the number of employees involved and their average hourly rates, then extrapolate this figure annually. The resulting number often surprises financial decision-makers, revealing substantial productivity losses that directly impact profitability.

Space utilization costs provide another critical metric for your financial analysis. Modern industrial facilities represent significant real estate investments, with costs calculated per square or cubic meter. Evaluate how much vertical space remains unused in your current configuration and calculate the equivalent rental value of this wasted capacity. Additionally, consider the opportunity cost of floor space that could be repurposed for revenue-generating activities if storage were optimized vertically rather than horizontally. Inventory damage and scrap costs must also be accounted for, including materials scratched, bent, or otherwise compromised due to improper storage conditions. Finally, consider opportunity costs related to delayed orders, production bottlenecks, or missed business opportunities caused by inefficient material handling and storage limitations.

Calculating Investment Requirements and Implementation Costs

The second phase of your financial analysis involves detailed assessment of the complete investment required for implementing a Herochu Cantilever Rack System. The equipment cost represents the most obvious component, encompassing the physical racking structure itself. However, a comprehensive financial assessment must also include shipping and transportation expenses, professional installation costs, and any necessary site preparation requirements. These might include floor reinforcement, electrical work for lighting improvements, or modifications to material handling equipment to optimize integration with the new storage system. Additionally, consider any training costs associated with familiarizing your team with the new system’s operation and safety protocols.

When evaluating equipment options, it’s essential to consider not only the initial purchase price but also the long-term value proposition. Herochu systems, manufactured to CE, EU, and ISO 9001 standards, represent engineered solutions designed for decades of reliable service. While alternative solutions might appear less expensive initially, they often incur higher long-term costs through increased maintenance requirements, shorter service life, or limited adaptability to changing operational needs. The true value of an investment in Herochu cantilever racking emerges through its durability, flexibility, and ability to support evolving business requirements without requiring complete replacement or significant modification.

Projecting Financial Returns and Payback Period

With comprehensive data on both current costs and required investment, you can now calculate the projected financial returns of implementing a cantilever racking system. The payback period represents perhaps the most straightforward and compelling metric for financial decision-makers. This calculation simply divides the total project investment by the annual savings identified through your cost analysis. For example, a $50,000 investment that eliminates $25,000 in annual wasteful expenses yields a two-year payback period. This means the system completely pays for itself within twenty-four months of implementation, after which it continues generating pure savings and efficiency improvements.

Beyond the simple payback period, calculating the return on investment over a typical equipment lifecycle provides even more compelling financial justification. Most high-quality cantilever racking systems deliver reliable performance for ten years or more with proper maintenance. Extending your financial analysis across this timeframe demonstrates the compound benefits of your investment. Using the previous example, a $50,000 investment that generates $25,000 in annual savings produces a 150% return over five years and substantially higher returns when projected across the system’s complete service life. These calculations transform the perception of cantilever racking from a simple storage solution to a high-return capital investment comparable to other profit-generating business initiatives.

Presenting Your Business Case to Financial Decision-Makers

The final step in securing approval for your cantilever racking investment involves effectively communicating your financial analysis to stakeholders responsible for capital allocation. Structure your presentation to first establish the current operational challenges and their quantified financial impact, then introduce the Herochu solution as the mechanism for addressing these issues. Present clear, conservative calculations that demonstrate both the payback period and long-term return on investment. Supplement your financial data with qualitative benefits including improved safety, reduced risk of inventory loss, and enhanced operational flexibility. These factors, while more difficult to quantify precisely, contribute significantly to the overall business case.

Emphasize the strategic nature of this investment by highlighting how optimized storage infrastructure supports broader business objectives including scalability, customer responsiveness, and competitive advantage. Discuss how the system’s flexibility accommodates business growth and product line expansions without requiring additional capital investments. Provide references to industry standards and certifications that validate the quality and reliability of your proposed solution. Most importantly, position your proposal not as a request for funding but as a recommendation for a proven strategy to reduce operational costs and improve profitability. This approach transforms the conversation from whether to spend money to how best to invest in the company’s operational infrastructure for maximum financial return.

Implementing Your Investment for Maximum Returns

Once approved, proper implementation becomes crucial for achieving the projected returns on your cantilever racking investment. Work closely with your Herochu representative to ensure optimal system configuration for your specific operational requirements. Develop a detailed implementation plan that minimizes disruption to ongoing operations while maximizing the system’s operational benefits from day one. Train your team on proper loading techniques, safety protocols, and inventory management practices that leverage the system’s full capabilities. Establish performance metrics to track the actual savings and efficiency improvements following implementation, providing tangible validation of your investment decision and creating a foundation for future capital investment proposals.

The financial case for implementing a Herochu Cantilever Rack System extends far beyond simple storage improvement. It represents a strategic investment in operational excellence that generates measurable financial returns through reduced labor costs, optimized space utilization, decreased inventory shrinkage, and enhanced operational flexibility. By applying rigorous financial analysis to storage challenges and presenting these findings effectively to decision-makers, operations professionals can secure the resources needed to transform their storage operations from cost centers to profit drivers. The result is not just better organized inventory, but improved financial performance and competitive advantage in an increasingly challenging business environment.