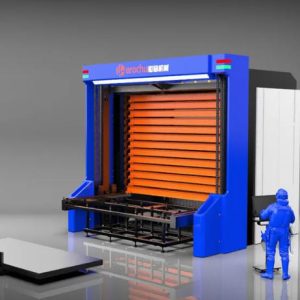

Herochu Universal Laser Automation for Laser Cutting Machines

From $8 900, CE/EU/ISO 9001 verified, tailored to any 3015-6025 mm laser

A laser head that slices 30 mm mild steel in a single pass deserves a feeding partner that never blinks. Herochu Universal Laser Automation is that partner: one hardware platform that loads, unloads, sorts and stores sheet from 0.5 mm aluminium foil to 50 mm ship plate without re-tooling or manual shims. Install the cell in the morning, press cycle start before lunch, and let the night shift go home early—productivity climbs while labour cost flat-lines.

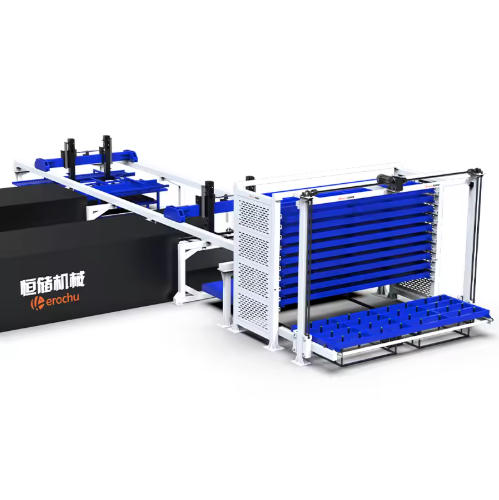

Built around your laser, not the other way around

The shuttle frame is built from laser-cut S355 steel, stress-relieved at 620 °C, then milled in one pass to guarantee ±0.05 mm rail parallelism. That may sound excessive, but when a 40 kW fibre beam moves at 350 m/min, 0.1 mm gap difference between suction cups can mean a dropped sheet and a scorched nozzle. Linear rails are 25 mm THK profiled blocks, preload class C1, rated 42 kN per runner block. Chain is a 1 ¼” duplex unit, 80 kN break load, guided inside the rail so grinding dust cannot settle on the links. Vertical lift uses two 1.5 kW helical gear-motors connected by an electronically synchronised inverter; if one side ever sees more than 2 % positional error, the system coasts to a stop and flags maintenance—no sheet skew, no crashed pallet.

Vacuum circuit that thinks for itself

A 5.5 kW side-channel blower generates 4 200 m³/h at –300 mbar, enough to lift 5 t with a safety factor 2.5. Yet suction is only half the story: twelve zone valves open and close according to sheet size, so a 1 500 × 3 000 mm plate uses six cups while a 1 000 × 1 000 mm part uses three. That saves 30 % cycle time and eliminates the “whistle” of closed cups sucking air. A mechanical vacuum reservoir maintains holding force for five minutes if power fails; during a city-wide blackout test in Warsaw the tower held a 25 mm sheet for 18 minutes without drop.

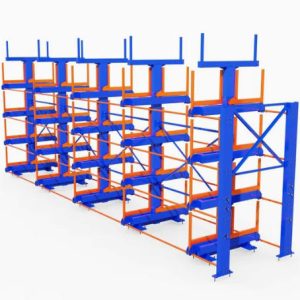

Storage tower that respects floor space

Footprint is 1 200 × 2 500 mm for 3015 machines, 1 400 × 3 200 mm for 6025. Height starts at 3 600 mm (eight shelves) and rises to 6 100 mm (thirteen shelves). Each shelf carries 3 t as standard; upgrade to 5 t by swapping four bolts and adding a 40 × 40 mm stiffener—no second frame to buy. Shelves are laser-zinc-coated S355, 4 mm deck with 50 mm pitch slots for adjustable locators. A 200 mm clear opening accepts bent parts or glued blanks; optional 300 mm opening is a five-minute sleeve swap. Forklift pockets in the base let you move the entire tower with a 5 t truck if you rearrange the hall.

Speed that keeps the beam busy

Vertical lift 9 m/min, shuttle travel 12 m/min. A 4 m × 2 m sheet travels from shelf to laser table in 38 seconds including pause for sheet probing. That is fast enough to feed a 12 kW laser cutting 6 mm stainless at 45 m/min without torch idle. Shuttle acceleration is capped at 0.6 m/s²; cups stay locked until deceleration is complete, so 0.5 mm mirror-finish aluminium arrives without slip marks.

EtherCAT backbone, no black boxes

All motion control, I/O and safety run over EtherCAT, cycle time 1 ms. You receive the ESI file; plug into Beckhoff, Bosch, B&R or any EtherCAT master and the tower appears as a single node. No proprietary gateway, no annual licence. If you prefer Profinet or Ethernet/IP, swap the bus coupler—five minutes, no rewiring. Source code is ladder and structured text; you may modify, back-up or migrate to another integrator at will.

Safety that satisfies insurers and unions

Category 3 PLd safety relays monitor every guard switch and light curtain. A 1 800 mm high polycarbonate wall plus 14 mm steel mesh prevents access while the shuttle is above 200 mm. If the curtain is breached, the drive coasts to stop in <250 mm and dumps vacuum so the sheet stays on the shelf, not on the floor. The entire cell carries CE declaration to EN ISO 13849-1, EN 60204-1 and EN 13105-2 static steel storage. We also supply a template for your CE technical file so the completed laser system can be placed on the EU market without additional conformity assessment.

Energy and air, real numbers

Average power draw during a 4 000 h two-shift year is 0.9 kW including blower, drives and controls—less than a domestic kettle. Compressed air is zero: the blower is electric, so you avoid the 1 kWh penalty that compressed-air grippers add for every sheet. Annual energy cost is under €650 at German industrial tariffs, a figure the finance team will barely notice.

Installation that respects uptime

The tower ships in five bolt-together modules: base, lift mast, shuttle bridge, suction beam and control cabinet. Two technicians with a 5 t forklift and a mobile crane can commission in one shift. All cables are numbered and plugged into Harting connectors; no terminal stripping on site. A laser tracker checks rail straightness; if your floor is within ±5 mm we shim nothing—tighten the M20 anchors and start production. We stay online via secure VPN until the first 100 sheets are cut, signed-off and archived.

Service that travels light

Chain elongation is tracked by an inductive sensor on the tensioner; the HMI warns at 2 %, usually after seven years of two-shift work. Bearings are sealed for life; first replacement is year twelve. Critical spares are warehoused in Rotterdam and Chicago; we ship the same day and remote-diagnose while the box is in the air. A full maintenance contract costs 3 % of purchase price per year and includes annual calibration of load cells and safety relays.

Price list that starts where you are

- Eight-shelf tower, 3 t rating, 3015 format: $8 900

- Each extra shelf: $590

- 5 t upgrade: +25 %

- 6025 format: +18 %

- Part sorting module with fork fingers: $3 200

- Stainless suction cups for aluminium: $450

Prices are FOB Shanghai; DDP EU or USA available. Lead time is 45 calendar days for standard spec, 60 days for ATEX sensors or tropical paint.

ROI you can defend

A Polish subcontractor cutting 300 t per month on two 15 kW lasers reported 71 h/month loading time before automation. After Herochu install the same tasks took 9 h, releasing 62 h of laser and labour capacity. At €85 machine-hour rate the monthly saving is €5 270; payback on a $16 800 cell arrived in 3.2 months. Add the drop in scratch rejections from 1.8 % to 0.2 % and the finance director asked for two more towers the same quarter.

Next move

Email us the make and model of your laser, the sheet sizes you store and the hook height of your crane. We return a 3-D PDF drawing, floor-loading diagram and locked price valid for 60 days. Order one tower; expand later by docking a second unit to the same out-feed conveyor—no software rewrite, no downtime.

Stop guarding the loading table. Let Herochu Universal Laser Automation feed your laser at the speed it was built to cut, and give your operator the freedom to make money instead of moving metal.