Herochu Warehouse Sheet Storage Racks and Industrial Shelving: Transform Your Warehouse’s Productivity

In modern manufacturing, construction, and metalworking, warehouse storage isn’t just about “holding materials”—it’s about keeping operations moving, protecting valuable inventory, and making the most of every square foot. Traditional storage methods for sheet materials—vertical stacking, fixed racks, or floor piles—fall short: they waste space, slow down retrieval, and damage expensive sheet metal, aluminum, or wood panels. Herochu’s Warehouse Sheet Storage Racks and Industrial Shelving solve these problems with innovative design, industrial-grade durability, and full customization. Starting at $3,660 and certified to CE, EU, and ISO 9001 standards, these systems turn disorganized warehouses into streamlined hubs of efficiency, helping businesses cut costs and boost productivity.

The Problem with Traditional Sheet Storage: Why You Need a Better Solution

Before investing in new storage, it’s critical to understand why old methods hold your warehouse back. Most facilities relying on traditional systems face three costly challenges:

First, wasted space. Vertical stacking or fixed industrial shelving leaves gaps—between layers, along walls, or under tall racks—that add up to 25-30% of unused warehouse area. For a 10,000 sq. ft. facility paying

7,000/monthinrent,that’s2,100 wasted every month on empty space.

Second, slow, labor-heavy retrieval. To grab a single sheet of steel from a stack, workers often have to move 5-10 other sheets first—taking 20-30 minutes per retrieval and requiring 2-3 people to avoid injury. This drags down production schedules and inflates labor costs.

Third, material damage. Sheet metal, aluminum, and finished wood panels scratch easily, warp under pressure, or dent at the edges when stacked. A steel fabrication plant in Texas reported losing $5,000/month to damaged stock before switching to Herochu—costs from reordering, reworking, and delaying customer orders.

Herochu’s Warehouse Sheet Storage Racks and Industrial Shelving are engineered to fix all three. By focusing on horizontal storage, modular flexibility, and user-friendly access, they eliminate waste and turn storage into a competitive advantage.

Horizontal Design: Maximize Space to Cut Rental and Expansion Costs

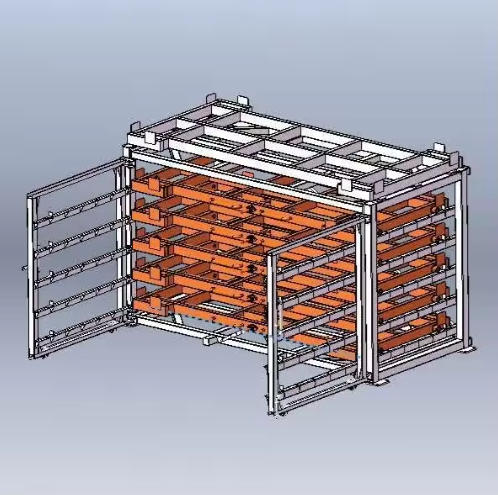

The biggest breakthrough in Herochu’s Warehouse Sheet Storage Racks is their horizontal layout—a departure from traditional vertical stacking that wastes space and risks damage. Horizontal storage lets you use every inch of your warehouse’s vertical and horizontal space, boosting storage density by 30% or more.

Each rack is customizable in layer count (from 2 to 10, with custom configurations available) and layer spacing (adjustable between 50mm and 200mm). This means you can store thin 1mm aluminum sheets on one layer and thick 20mm steel plates on another—no gaps, no wasted height. The horizontal orientation also eliminates the “top-heavy” risk of vertical racks, making the system safer for workers and more stable for heavy loads.

A construction firm in Ohio saw immediate results after installing Herochu’s horizontal racks. “We used to rent an extra 3,000 sq. ft. to store sheet metal,” said their warehouse manager. “Now we fit everything in our original space—saving $25,200 a year in rent. The racks paid for themselves in 8 months.”

This efficiency isn’t just about fitting more material—it’s about future-proofing your warehouse. As your business grows, you won’t need to lease additional space; you’ll just adjust your Herochu racks to handle more inventory.

Modular Flexibility: Adapt to Changing Materials and Demands

Manufacturing and construction don’t stand still—one month you’re storing 4x8ft drywall sheets, the next 10ft steel plates for a commercial project. Rigid industrial shelving can’t keep up, leaving you with unused capacity or overcrowded racks. Herochu’s Warehouse Sheet Storage Racks are fully modular, so you can reconfigure them in hours, not days.

Need to add a layer for new aluminum stock? Simply attach new support beams—no welding or heavy tools required. Want to widen shelves for longer sheets? Adjust the side panels to fit. The racks also work with optional accessories: remnant pallets for small offcuts, dividers for sorting by material type, or locking mechanisms for high-value sheets.

A machinery plant in Michigan relies on this flexibility for their diverse projects. “One week we’re storing thin copper sheets for electrical parts, the next thick steel for machine frames,” their supervisor explained. “With Herochu, we just adjust the layers—no need to buy new racks. We’ve saved $15,000 in equipment costs over two years.”

This adaptability means your initial investment in Herochu’s Industrial Shelving grows with your business. You won’t be stuck with a system that becomes obsolete when your material needs change.

User-Friendly Access: Cut Labor Time and Reduce Injury Risk

Traditional sheet storage requires brute force: 2-3 workers lifting heavy sheets, shifting stacks, and struggling to reach materials at the back of racks. This isn’t just slow—it’s dangerous. Musculoskeletal injuries from lifting are one of the top causes of warehouse downtime, costing businesses thousands in workers’ compensation and lost productivity.

Herochu’s Warehouse Sheet Storage Racks eliminate this with 100% extractable, wheeled drawers. A single worker can slide a drawer out to access any sheet—no lifting, no shifting other materials, no waiting for help. The drawers glide on industrial-grade linear rails, even when loaded with 5T of steel, making retrieval smooth and safe.

The Ohio construction firm saw a 40% drop in retrieval time after switching to Herochu. “What used to take two people 30 minutes now takes one person 15 minutes,” their manager said. “Labor costs are down 20%, and we haven’t had a lifting injury in over a year. That’s priceless.”

For facilities using cranes, jibs, or vacuum lifters, the design is even better: drawers extend far enough to load/unload directly, eliminating the need to maneuver heavy equipment into tight spaces. This streamlines workflows and keeps production on track.

Material Protection: Minimize Waste and Maintain Quality

Sheet materials are only valuable if they arrive at the production line undamaged. Traditional stacking crushes edges, scratches surfaces, and warps thin sheets—turning expensive inventory into scrap. Herochu’s Warehouse Sheet Storage Racks protect your stock with a design that prioritizes material integrity.

Each drawer has a powder-coated steel surface that resists scratches and corrosion, while the horizontal layout keeps sheets flat, preventing warping from vertical pressure. The separated storage eliminates friction between sheets, so aluminum panels stay shiny and steel plates remain dent-free.

Certifications and Value: Invest in Durability and Compliance

Herochu’s Warehouse Sheet Storage Racks and Industrial Shelving aren’t just efficient—they’re built to last and meet global standards. Every system is certified to CE, EU, and ISO 9001 standards, meaning it passes strict tests for load capacity, structural integrity, and safety. The racks are constructed from high-carbon steel, reinforced at stress points, and finished with a corrosion-resistant powder coat—ensuring they withstand years of heavy use in harsh workshop environments.

At $3,660, Herochu’s racks are an investment—but one that delivers fast ROI. The average customer recovers their cost within 12 months, thanks to rent savings, labor cuts, and reduced material waste. And with a 5-year warranty on all structural components, you won’t have to worry about unexpected repair costs.

Choose Herochu: Transform Your Warehouse Today

Herochu’s Warehouse Sheet Storage Racks and Industrial Shelving aren’t just storage systems—they’re solutions to the biggest challenges facing modern warehouses. Whether you’re struggling with wasted space, high labor costs, or damaged materials, these racks adapt to your needs and deliver measurable savings.

Customizable to your workshop, backed by global certifications, and designed for long-term durability, Herochu’s Industrial Shelving is the smart choice for businesses that want to work smarter, not harder. Contact Herochu today to discuss your storage needs and get a personalized quote. With our racks, you’re not just buying storage—you’re building a more efficient, profitable, and sustainable warehouse.