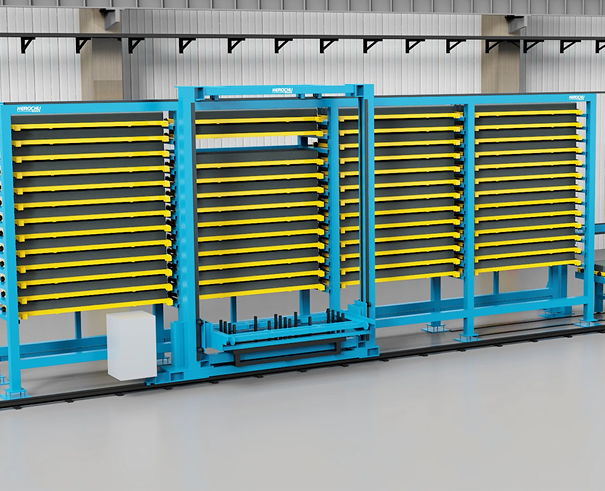

Four-Bay Metal Sheet Storage Warehouse

For businesses managing large volumes of sheet metal—whether in distribution centers, fabrication plants, or industrial warehouses—the challenge isn’t just storing materials; it’s doing so in a way that supports speed, accuracy, and safety. Enter the four-bay metal sheet storage warehouse: a scalable, industrial-grade solution engineered for maximum throughput and minimal waste.

Four-Bay Metal Sheet Storage Warehouse – Revolutionize Material Handling in High-Volume Operations

For businesses managing large volumes of sheet metal—whether in distribution centers, fabrication plants, or industrial warehouses—the challenge isn’t just storing materials; it’s doing so in a way that supports speed, accuracy, and safety. Enter the four-bay metal sheet storage warehouse: a scalable, industrial-grade solution engineered for maximum throughput and minimal waste.

The Hidden Costs of Disorganized Sheet Storage

Many operations underestimate how much time and money are lost due to poor storage practices. Sheets leaning against walls, mixed batches, unlabeled stacks—all contribute to delays, damaged inventory, and frustrated workers. In high-volume settings, even a 5% inefficiency can translate to thousands in annual losses.

The four-bay metal sheet storage warehouse eliminates these issues through a structured, bay-based architecture that brings warehouse-level discipline to shop-floor storage.

Core Advantages of the Four-Bay Design

1. Zoned Storage for Operational Clarity

Each of the four bays functions as an independent storage zone, ideal for separating materials by:

- Alloy type (e.g., aluminum vs. galvanized steel)

- Thickness or gauge

- Supplier or delivery batch

- Active project or customer order

This zoning reduces cross-contamination of materials and ensures that the right sheet is always pulled for the right job—on the first try.

2. Faster Turnaround with Direct Access

Unlike pallet racking systems that require forklifts and aisle clearance, the four-bay warehouse features front-loading cassettes accessible at ground level or via mezzanine platforms. Operators can retrieve sheets manually or with vacuum lifters without navigating narrow aisles or waiting for equipment. This direct access slashes retrieval time by up to 40%.

3. Floor Space Optimization Through Vertical Density

By stacking cassettes vertically within each bay, the system achieves high storage density without sacrificing accessibility. A single unit can hold hundreds of sheets while occupying less than 100 square feet—ideal for facilities operating under spatial constraints.

4. Damage Prevention and Material Integrity

Sheets are stored vertically in fully enclosed cassettes with reinforced edges and anti-scratch liners. This prevents contact between sheets, eliminating scuffing, burring, or edge deformation—critical for industries like architectural metalwork or precision machining where surface finish matters.

5. Streamlined Inventory Control

Each bay can be integrated with barcode or RFID tagging systems for digital tracking. But even without tech, the open design allows visual audits in seconds. Managers can spot low-stock items, identify surplus materials, and plan procurement with confidence—reducing both emergency orders and dead stock.

Safety as a Foundation, Not an Afterthought

Worker safety is built into every aspect of the four-bay warehouse:

- No loose sheets leaning or falling

- Stable base frames prevent tipping

- Smooth edges and rounded corners minimize injury risk

- Clear walkways between bays improve traffic flow

These features not only protect your team but also reduce insurance premiums and liability exposure.

Scalable from Startup to Enterprise

Whether you’re a mid-sized fabricator or a national distributor, the modular nature of the four-bay system allows seamless expansion. Start with one unit and add adjacent bays as demand grows. Components are standardized, ensuring compatibility across installations.

Real-World Impact: Case in Point

A Midwest metal service center implemented the four-bay warehouse across three production lines. Within six months, they reported:

- 22% reduction in material handling labor

- 15% decrease in sheet damage claims

- 30% faster setup times for new jobs

- Complete elimination of “lost sheet” incidents

Who Benefits Most?

This system shines in:

- Service centers distributing cut-to-length sheets

- Large-scale fabricators running multiple concurrent projects

- Automotive OEM suppliers managing JIT inventory

- Renewable energy contractors storing solar mounting plates or wind tower components

Conclusion: Storage That Works as Hard as You Do

The four-bay metal sheet storage warehouse is more than hardware—it’s a workflow enabler. It turns material storage from a passive cost center into an active driver of efficiency, quality, and safety. In an era where lean operations define competitive advantage, this system delivers measurable, lasting value.

Don’t let disorganization dictate your productivity. Reclaim control with a storage solution designed for the demands of modern metalworking.

Factory

Hot Selling Machines

-

Heavy Duty Sheet Metal Storage Racks

Intelligent Production Line CNC Automated Storage Rack: Precision Meets Automation

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drawer-Style Sliding Sheet Metal Storage Rack – Efficient & Safe Material Handling

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Design for Steel Plate Storage with Heavy Duty Drawer Type Sheet Metal Rack Storage System

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Rack for Heavy Plates and Molds: Durable, Efficient Storage for Industrial Applications

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drive-In Pallet Rack Alternative: Space-Saving Drawer-Type Sheet Metal Storage with Automated Retrieval Compatibility

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Drawer Type Plate Shelves Warehouse Rack System for Industrial Metal Storage – 3-Ton Capacity per Layer

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Warehouse Storage System: Customizable Solutions for Metal Plate & Industrial Storage

Read moreRated 0 out of 5 -

Automated Storage Systems

Smart Fixed Profile Stereo Warehouse: Cost-Effective Automation for Small to Mid-Sized Fabrication Shops

Read moreRated 0 out of 5

Related products

Related products

-

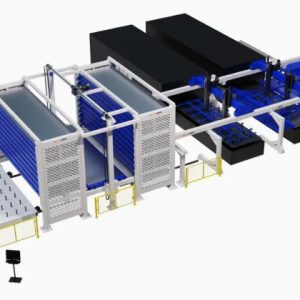

Automation Sheet Metal Material Warehouse

Automatic Sheet Metal Storage & Retrieval System (AS/RS) – Automated Loading Unloading Racks

Read moreRated 0 out of 5 -

Automation Sheet Metal Material Warehouse

Maximizing Efficiency with Dual-Tower Automated Storage Solutions

Read moreRated 0 out of 5 -

Automation Sheet Metal Material Warehouse

Fully Automatic Vertical Profile Smart Storage Unit

Read moreRated 0 out of 5 -

Automation Sheet Metal Material Warehouse

Automated Vertical Storage for Bars and Tubes

Read moreRated 0 out of 5