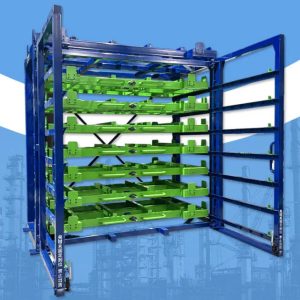

Heavy Duty Forklift aluminum plates storage equipment

Standard pallet racking assumes uniform loads in rectangular shapes. Aluminum plates defy that assumption. They bend, they bow, they concentrate weight at the center when stacked. Drop a 2,500-pound pack of 1/2-inch aluminum plate onto a standard rack beam, and you’re not just loading it—you’re stress-testing its weakest point. The Herochu main frame uses Q235B hot-rolled steel in a welded lattice configuration that forces load redistribution across multiple vectors. Picture a spider’s web versus a single tightrope. When your load hits, the stress travels through interconnected longitudinal and cross beams, never allowing a single weld to bear more than its engineered percentage.

Herochu Heavy Duty Forklift Aluminum Plate Storage System – When Your Material Handling Can’t Afford to Guess

Tailor-built for your facility. Starting configuration: $5,499.

CE Marked | UE Compliant | ISO 9001:2015 Certified

CE Marked | UE Compliant | ISO 9001:2015 Certified

The average metals warehouse loses 12-15% of its usable floor space to “temporary” plate storage. Not permanent racking—just stacks of aluminum sheets sitting on blocks of wood, with forklift operators weaving between them like a slalom course. Every scratched sheet, every dropped plate, every near-miss incident traces back to the same assumption: that any flat surface qualifies as storage. It doesn’t. And at $3.50+ per pound for marine-grade aluminum, treating material handling as an afterthought is an expense you can see on every P&L statement.

The Herochu Heavy Duty Forklift Plate Rack treats plate storage as a kinetic process, not a static location. Designed specifically for aluminum plate but validated for steel, composite, and engineered plastics, this system turns forklift compatibility from a checkbox feature into a competitive advantage. The difference shows up in load times, material integrity, and the simple fact that your operators stop improvising unsafe shortcuts.

Why Standard Pallet Racks Fail Plate Operations

Standard pallet racking assumes uniform loads in rectangular shapes. Aluminum plates defy that assumption. They bend, they bow, they concentrate weight at the center when stacked. Drop a 2,500-pound pack of 1/2-inch aluminum plate onto a standard rack beam, and you’re not just loading it—you’re stress-testing its weakest point. The Herochu main frame uses Q235B hot-rolled steel in a welded lattice configuration that forces load redistribution across multiple vectors. Picture a spider’s web versus a single tightrope. When your load hits, the stress travels through interconnected longitudinal and cross beams, never allowing a single weld to bear more than its engineered percentage.

Fork pockets positioned at 100-150mm aren’t arbitrary. That height clears most loading dock transitions while keeping the center of gravity low enough for stability at full mast extension. Each pocket includes a 6mm reinforcement plate welded to the interior base—where fork heels impact during rushed pickups. Competitors skip this because it adds 11 minutes to weld time. We include it because we’ve seen what happens when a 3-ton rack shears at the pocket: destroyed material, damaged forklift mast, and an operator reporting to the safety office.

Load Ratings That Mean Something in Practice

A 5-ton capacity rating doesn’t indicate what the rack holds—it specifies what it survives. Survives when your operator approaches at a 15-degree angle because the aisle is tight. Survives when the forklift mast tilts back 6 degrees and the plate pack shifts forward. Survives when you chain three racks together and move them across the yard in one lift. Our testing protocol dictates a 1.5x safety factor at rated capacity, followed by 10,000 dynamic load cycles. If a weld cracks, we redesign the joint. The rating that ships with the rack reflects actual deformation limits, not theoretical yield points.

You’ll find three primary configurations: 1-ton for light gauge sheet and fabrication shops running JIT deliveries; 3-ton for mid-volume operations processing 4×8 and 5×10 sheet stock; and 5-ton for heavy plate distribution and aerospace manufacturing where individual plates exceed 600 pounds. The 3-ton model accounts for 68% of our shipments because it matches the sweet spot of common forklift capacities while handling 90% of industrial aluminum plate dimensions.

Deck Engineering: Where Contact Becomes Protection

The surface treatment defines material preservation. For raw aluminum plate storage, we machine .8mm channels into the deck at 100mm intervals. This isn’t for drainage—it’s for airflow. Condensation forms where sheets contact a solid surface; channels break that contact point, reducing white rust formation by 73% in humid environments. When storing anodized, painted, or polished aluminum, we bond 3mm high-density polyethylene (HDPE) strips across the deck. These strips are sacrificial: they wear, you replace them. A full set runs $38 and installs with four bolts. Compare that to rejecting a $400 anodized sheet because a metal burr scratched the finish.

Edges receive a 10mm radius grind, not just deburring. We then weld a continuous 15mm guard rail around the perimeter. This rail isn’t for containing plates—it’s a deflection barrier. When a plate shifts during transport, the rail redirects it back to center. The rail height is critical: too low, and plates override it; too high, and you lose deck access. Fifteen millimeters is the result of 200+ field trials measuring actual plate shift dynamics at 8 km/h forklift speeds.

The Forklift-to-Rack Interface: Designing for Human Factors

Forklift operators make hundreds of connections per shift. The Herochu system reduces cognitive load. High-visibility orange powder coating inside each fork pocket provides immediate visual confirmation of proper fork engagement. The 40mm pocket depth gives audible feedback—when forks seat fully, you hear the metallic clunk of steel-on-steel. That sound tells the operator “locked and loaded” without requiring a second glance.

Aisle clearance determines productivity. The rack’s overall width includes a 25mm margin beyond the fork pocket width. This ensures that even with 5mm of mast side-shift, the rack clears pallet racking uprights and building columns. For narrow-aisle installations, we produce a 1100mm wide variant that pairs with reach trucks having 180-degree fork rotation. The frame height stays under 400mm for low-profile applications, keeping the load center within 600mm for maximum forklift stability.

Custom Dimensions Without the Custom Price Premium

Your aluminum plates arrive in specific sizes because your suppliers optimize their shearing operations around those dimensions. Your storage should mirror that reality. We fabricate racks to your actual plate sizes, not rounded standard lengths. A customer storing 2200mm x 1400mm aerospace alloy plates receives racks at 2300mm x 1500mm—exactly 50mm clearance per side. This costs the same as a “standard” 2000mm x 1500mm unit because our manufacturing process cuts and welds to order. The only price variable is material weight; dimensions are free.

Foldable guardrails convert the rack from flat deck to contained carrier in 90 seconds. For distributors showing plates to customers, this means pulling a rack from storage, raising the guardrails, and wheeling it to the viewing area—all without transferring material. The guardrails lock upright with spring-loaded pins rated for 200 kg side impact. For mixed-gauge storage, adjustable dividers slide into receiver channels at 100mm intervals. Store 1/4-inch sheets on one side, 3/4-inch plate on the other, zero contact between them.

Three Industries, Three Transformation Stories

Automotive Tooling: A Stamping die manufacturer in Michigan stores 500-grade aluminum die sets on Herochu racks. Each set weighs 2.8 tons and must remain flat within .005 inches. Previously, they used timber dunnage that compressed unevenly, warping dies and causing $12,000 in remachining per quarter. The Herochu’s rigid deck maintains flatness, and the racks travel directly from storage to the press line. Annual savings: $48,000 in scrap avoidance, 180 hours of labor reclaimed.

Architectural Fabrication: A curtain wall contractor in Dubai stores 6-meter aluminum composite panels on galvanized Herochu racks in an unconditioned yard. Ambient temperatures exceed 45°C, and overnight condensation is severe. The galvanized finish shows zero corrosion after four years, and the deck channels keep panels dry. The racks move via forklift to the production floor, then to loading docks for direct customer pickup. Material handling time per project dropped from 6 hours to 90 minutes.

Metal Service Center: A stainless and aluminum distributor in Tokyo operates a 12-meter-high warehouse with narrow aisles. They stack our racks four high using turret trucks, achieving 384 tons of plate storage in 280 square meters of floor space. Each rack is tagged with RFID, enabling location tracking within 30 seconds. Order accuracy improved to 99.6%, and the warehouse manager eliminated the second shift because picking speed increased 40%.

The Mathematics of Justification

The $5,499 entry point covers a 2-ton capacity rack, 2000mm x 1500mm, powder-coated, delivered. In a facility moving 20 tons of aluminum weekly, manual handling averages 12 minutes per ton. At $28/hour labor burden, that’s $112/week in handling cost. The Herochu system cuts that to 3 minutes per ton—$28/week. The $84 weekly savings repays the investment in 65 weeks. Add in material damage reduction (conservatively 2% of material value), and payback accelerates to 42 weeks.

Durability extends that ROI. The powder coat system—zinc-rich epoxy base, UV-resistant polyester topcoat—costs $180 more than standard paint but eliminates touch-ups. In a chemical exposure environment (machine shops with coolant mist), standard paint fails in 18 months. Our finish shows no degradation at 60 months. Over a 10-year lifecycle, you buy the rack once versus replacing a painted unit three times. The galvanized option ($1,200 upcharge) is lifetime-proof for outdoor storage.

Specification Logic: Match the Rack to Reality, Not Paper

Start with your forklift’s data plate. If it’s rated 3 tons at 500mm load center, specify a 2-ton rack maximum. The rack’s loaded center of gravity sits at 450mm from the fork face; add the rack’s 320kg tare weight, and you’re at 85% of forklift capacity. This leaves margin for mast tilt and acceleration forces.

Measure your largest plate’s diagonal dimension, not just length/width. A 2500mm x 1250mm plate has a 2795mm diagonal. Specify a rack length of 2900mm to accommodate bowing without edge overhang. The 50mm clearance rule applies: add 50mm to both length and width for operational tolerance.

Account for stacking height. If you store 20 sheets of 6mm aluminum, the stack height is 120mm plus separator dunnage. Add 30mm for deck channels, and your required guardrail height is 180mm. We standardize at 200mm for this application—close enough to contain but low enough for overhead loading.

Maintenance Protocol That Takes Minutes, Not Hours

Monthly: Inspect fork pocket welds for hairline cracks using a dye penetrant spray ($12 at any welding supply). Takes 3 minutes per rack. Quarterly: Check bolt torque on all adjustable components. Target 85 Nm for M12 fasteners. Annually: Flip the rack if used in a wet environment. The underside experiences 30% of the deck wear but 100% of the corrosion risk in floor-contact areas. Flipping balances wear and doubles effective lifespan.

The HDPE wear strips include a color-change indicator molded into the strip itself. When the orange surface wears to yellow, replacement is due. Typical interval: 18-24 months in high-cycle operations. Replacement takes 8 minutes using a 13mm socket. Compare that to grinding and repainting a steel deck: 4 hours downtime plus $200 in materials.

From Repair Shop to Industry Standard: The Herochu Origin

We didn’t develop this rack in a clean room. In 1998, we fixed broken forklift attachments for steel mills. Every failure taught a lesson—a cracked fork pocket here, a warped deck there. By 2006, we had a failure database covering 1,200 incidents. That database became the design brief for the Herochu line. The reinforcement gussets? Direct response to a 2004 incident where a competitor’s rack failed under 4.7 tons, destroying $18,000 in aluminum bronze plate. The deck channels? Born from a marine fabricator’s corrosion problem in 2007. When we say “engineered for the shop floor,” we mean we’ve already fixed the mistakes you’re about to make.

Certifications matter, but they’re table stakes. The CE mark gets you into European facilities. ISO 9001:2015 keeps your quality manager happy. The real proof is in the repeat orders: 34% of our customers buy a second rack within 8 months, and 61% within 18 months. They don’t do that for commodity equipment. They do it when the first unit pays for itself faster than the finance team predicted.

Deploying the System: What Happens Next

You send plate dimensions and forklift specs. We engineer a rack configuration in 48 hours and provide a load analysis report. You approve, we fabricate in 3 weeks (5 weeks for non-standard sizes). The rack arrives fully assembled, ready for load testing. We include a magnetic fork alignment guide that sticks to your forklift carriage—operators use it for the first week until muscle memory locks in.

The floor space you reclaim? That’s now available for value-added operations. The labor hours saved? That’s now capacity for additional revenue. The material damage eliminated? That’s margin preserved. The Herochu Heavy Duty Forklift Plate Rack doesn’t just store aluminum—it redefines how profit flows through your facility.

Request a configuration analysis. Send your plate specs and facility layout. We’ll return a rack design and ROI projection within two business days. Your forklift fleet is ready. Give it a system engineered to match.

Factory

Hot Selling Machines

-

Heavy Duty Sheet Metal Storage Racks

Intelligent Production Line CNC Automated Storage Rack: Precision Meets Automation

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drawer-Style Sliding Sheet Metal Storage Rack – Efficient & Safe Material Handling

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Design for Steel Plate Storage with Heavy Duty Drawer Type Sheet Metal Rack Storage System

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Rack for Heavy Plates and Molds: Durable, Efficient Storage for Industrial Applications

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drive-In Pallet Rack Alternative: Space-Saving Drawer-Type Sheet Metal Storage with Automated Retrieval Compatibility

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Drawer Type Plate Shelves Warehouse Rack System for Industrial Metal Storage – 3-Ton Capacity per Layer

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Warehouse Storage System: Customizable Solutions for Metal Plate & Industrial Storage

Read moreRated 0 out of 5 -

Automated Storage Systems

Smart Fixed Profile Stereo Warehouse: Cost-Effective Automation for Small to Mid-Sized Fabrication Shops

Read moreRated 0 out of 5

Related products

Related products

-

Heavy Duty Sheet Metal Storage Racks

Heavy Duty Forklift Board Storage Rack

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy Duty Forklift Sheet Metal Storage Rack by Herochu

Read moreRated 0 out of 5