In industrial environments where raw materials like steel plates are the lifeblood of production, disorganized storage isn’t just an inconvenience—it’s a significant operational bottleneck and a serious safety hazard. Traditional flat stacking or inadequate racking leads to wasted floor space, damaged materials, time-consuming retrieval, and increased risk of workplace accidents. For operations requiring systematic, safe, and space-efficient storage of heavy plates, the solution is clear: Industrial Heavy Duty Steel Plate Shelving Units.

This comprehensive guide details how these engineered storage systems provide unparalleled strength, adaptability, and intelligent features to transform your material handling process.

Why Standard Shelving Fails for Heavy Plates

Standard warehouse shelving is designed for distributed loads—boxes, bins, or lighter items. Steel plates, however, exert immense, concentrated point loads. Standard racks often buckle, deflect, or fail under such stress. Furthermore, they lack the depth, height customization, and specialized features needed for large-format, heavy materials. The result is inefficient use of valuable cubic space and compromised safety.

Engineered for Extreme Loads: Core Strength & Specifications

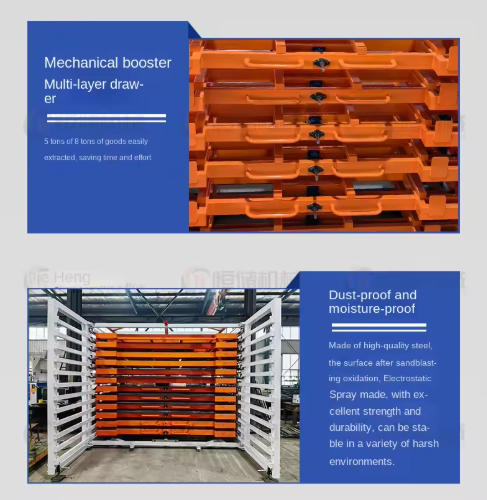

Industrial Heavy Duty Plate Shelving is built from the ground up to handle extreme weights. Constructed from high-grade structural steel with reinforced joints and heavy-duty beams, these units manage loads that would cripple conventional shelving. Each model is rated for clear, per-layer capacity to ensure safe and reliable operation.

Key Product Specifications:

| Model | Load Capacity (Per Layer) | Shelf Size (Depth x Width) | Customizable Layers | Overall Dimensions (LxWxH) |

|---|---|---|---|---|

| HC-B3015-63 | 3 Tons | 3.0m x 1.5m | Up to 6 | 3505x2280x2000mm |

| HC-B4015-65 | 5 Tons | 4.0m x 1.5m | Up to 6 | 4505x2280x2000mm |

| HC-B4020-68 | 8 Tons | 4.0m x 2.0m | Up to 6 | 4505x2280x2500mm |

| HC-B6020-610 | 10 Tons | 6.0m x 2.0m | Up to 6 | 6505x2280x2500mm |

These specifications serve as a foundation. The true advantage lies in the system’s comprehensive customization capabilities.

Total Customization: Designed for Your Exact Requirements

A one-size-fits-all approach doesn’t work for industrial storage. Our shelving systems are fully adaptable across three critical dimensions:

- Layer Customization: The number of shelves is not fixed. It is intelligently determined based on the thickness of your plates and your desired storage density. This ensures optimal vertical space utilization without compromising access or safety.

- Load-Bearing Customization: For specialized applications, we go beyond standard models. Our engineers can recommend and design specific reinforced guide rails and frame structures tailored to your maximum single-stack weight, ensuring a perfect match for your heaviest materials.

- Precision Dimensional Customization:

- For Your Materials: Shelf dimensions are calculated based on your largest plate size, with a recommended allowance (typically +500mm in length and width). This prevents overhang, protects plate edges, and facilitates easier handling with cranes or forklifts.

- For Your Facility: The most significant space-saving feature is customizable height. Units can be engineered to extend close to your factory ceiling, converting unused vertical space into high-density storage. This maximizes your storage ROI per square foot of floor space.

Safety by Design: Protecting Your Workforce and Assets

Safety is engineered into every component, addressing the unique hazards of heavy plate handling.

- Clear Load Signage: A prominent, durable maximum load sign is displayed on each unit. This critical visual warning clearly states the safe load limit per layer, preventing dangerous overloading—a primary cause of racking failures.

- Anti-Pinch Design: This intelligent feature incorporates a safety gap or a specialized structural design between the drawer and the frame. It effectively prevents operators’ fingers from being caught when pushing or pulling heavy shelves, addressing a common but serious industrial injury.

- Inherent Stability: The robust design and option for floor anchoring ensure exceptional stability, even when fully loaded, eliminating risks of tipping or shifting.

Operational Intelligence: Features for Streamlined Management

Beyond strength, these units incorporate smart features that drive productivity and accuracy.

- Integrated Label System: Each shelf front includes transparent label sleeves or a dedicated label area. This supports visual management by allowing easy insertion of material information cards (detailing grade, thickness, heat number, etc.), enabling instant inventory identification and reducing errors.

- Mechanized Handling Compatibility: These units are designed to integrate seamlessly with overhead lifting equipment. They work in concert with gantry cranes, bridge cranes, and jib cranes to enable fully mechanized storage and retrieval. This minimizes manual labor, drastically reduces handling time, and lowers the risk of musculoskeletal injuries.

- Accessory Integration for Complete Access:

- Mobile Ladder Trucks: For taller, customized units, matching mobile climbing platforms provide safe and convenient access to top-tier materials for inspection or manual retrieval of smaller items, ensuring every inch of the system is fully utilizable.

Industry Applications: Where Strength Meets Necessity

These shelving units are indispensable across a wide range of heavy industries, including:

- Metal Service Centers & Fabrication Shops: Storing raw plate stock for laser cutting, punching, bending, and welding.

- Shipbuilding & Maritime: Organizing large steel plates and sections for hull and superstructure construction.

- Heavy Equipment & Machinery Manufacturing: Managing thick plates for frames, booms, and buckets.

- Aerospace & Defense: Storing high-value metal and composite sheets.

- Construction & Pre-Cast Concrete: Holding large-format materials and reinforcement sheets.

The ROI of a Professional Storage System

Investing in a purpose-built heavy plate shelving system delivers measurable returns:

- Maximized Storage Density: Store significantly more material in the same floor space by utilizing full vertical height.

- Enhanced Safety Culture: Reduce accident rates, prevent material damage, and demonstrate a commitment to worker safety.

- Increased Operational Efficiency: Slash time spent searching for and retrieving materials, speeding up production workflows.

- Improved Inventory Control: The visual label system enables accurate, real-time stock management.

- Long-Term Durability: Built from industrial-grade materials, these systems offer a long service life with minimal maintenance.

Conclusion: Build a Stronger, Smarter Foundation

Our range of Industrial Heavy Duty Steel Plate Shelving Units represents the pinnacle of specialized storage solutions. By combining massive strength with intelligent customization, integrated safety features, and productivity-enhancing details, they provide a robust answer to the complex challenges of heavy industrial material handling.

Do not let inefficient storage constrain your productivity and compromise safety. Upgrade to a system engineered for your specific needs.

Contact our engineering team today for a complimentary storage audit and a custom shelving design proposal based on your plate specifications, load requirements, and facility layout. Let us help you build a safer, more organized, and highly efficient operation from the ground up.