Sheet Metal Material Handling Equipment

The sheet metal industry demands speed, consistency, and minimal waste. To meet these demands, forward-thinking manufacturers are turning to Sheet Metal Material Handling Equipment, particularly the Sheet Metal Arm Handling Manipulator, to automate loading, unloading, and positioning tasks. This shift not only boosts productivity but also enhances workplace safety and product quality.

The sheet metal industry demands speed, consistency, and minimal waste. To meet these demands, forward-thinking manufacturers are turning to Sheet Metal Material Handling Equipment, particularly the Sheet Metal Arm Handling Manipulator, to automate loading, unloading, and positioning tasks. This shift not only boosts productivity but also enhances workplace safety and product quality.

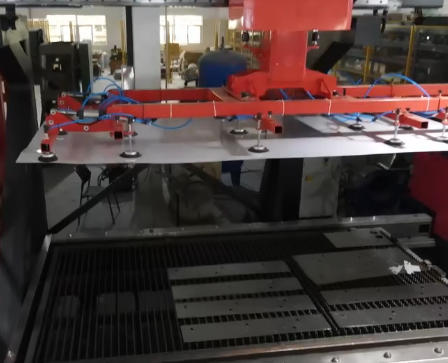

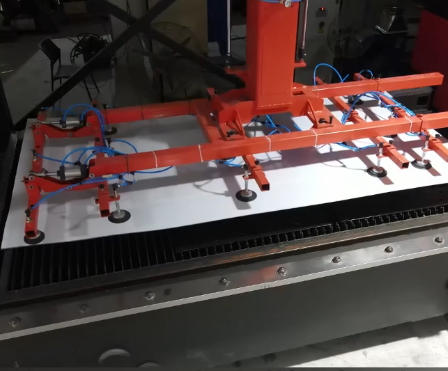

Unlike traditional methods that rely on overhead cranes or manual lifting, modern Sheet Metal Material Handling Equipment uses precision-engineered arms equipped with vacuum systems to handle delicate yet heavy metal sheets—ranging from thin 1mm foils to robust 20mm plates—without deformation or slippage.

Core Features Driving Adoption

The Servo Swing Arm Manipulator for Automated Material Handling stands out due to its:

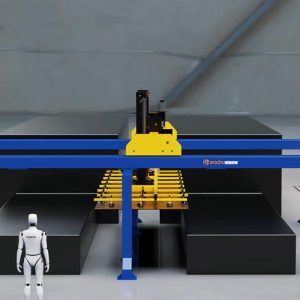

- High space utilization: Its cantilever design retracts when not in use, freeing up valuable floor space.

- Automated operating processes: Seamless integration with CNC punch presses, press brakes, and laser cutters enables lights-out manufacturing.

- Versatility: Capable of handling various materials—steel, aluminum, copper, even composites—making it ideal for job shops with diverse orders.

For instance, the Herochu HC-R3015 series supports feeding formats from 1250×1000mm up to 3000×1500mm, with load capacities of 300–500kg. Larger models like HC-R4020-750 extend this to 4000×2000mm and 750kg, accommodating industrial-scale requirements.

How It Works in Real Production

Imagine a typical workflow: raw sheets are stacked on a pallet. The Sheet Metal Arm Handling Manipulator activates, extends its arm, lowers suction cups onto the top sheet, lifts it smoothly, and transfers it to the laser cutter’s worktable. Sensors verify alignment before release. The entire cycle takes under 30 seconds—compared to 2–3 minutes manually.

This automation eliminates common issues like:

- Scratches from improper handling

- Misalignment causing cutting errors

- Worker strain from repetitive lifting

Furthermore, the system’s ergonomic interface allows even novice operators to manage complex sequences with minimal training. Safety features like dual-channel emergency stops and collision detection ensure compliance with OSHA and CE standards.

Economic and Strategic Benefits

Labor shortages and rising wages make automation economically compelling. A single manipulator can replace two full-time workers, saving 80,000–120,000 annually in direct labor costs alone. Plus, with consistent feeding, material utilization improves—reducing scrap rates by 5–10%.

Importantly, these systems support just-in-time manufacturing. Quick changeovers between jobs mean shorter lead times and higher customer satisfaction—critical in industries like automotive, HVAC, and appliance manufacturing.

In summary, investing in Sheet Metal Material Handling Equipment is a strategic move toward operational excellence. As competition intensifies and margins tighten, automation isn’t just about efficiency—it’s about survival.

Factory

Hot Selling Machines

-

Heavy Duty Sheet Metal Storage Racks

Intelligent Production Line CNC Automated Storage Rack: Precision Meets Automation

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drawer-Style Sliding Sheet Metal Storage Rack – Efficient & Safe Material Handling

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Design for Steel Plate Storage with Heavy Duty Drawer Type Sheet Metal Rack Storage System

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Rack for Heavy Plates and Molds: Durable, Efficient Storage for Industrial Applications

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drive-In Pallet Rack Alternative: Space-Saving Drawer-Type Sheet Metal Storage with Automated Retrieval Compatibility

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Drawer Type Plate Shelves Warehouse Rack System for Industrial Metal Storage – 3-Ton Capacity per Layer

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Warehouse Storage System: Customizable Solutions for Metal Plate & Industrial Storage

Read moreRated 0 out of 5 -

Automated Storage Systems

Smart Fixed Profile Stereo Warehouse: Cost-Effective Automation for Small to Mid-Sized Fabrication Shops

Read moreRated 0 out of 5

Related products

Related products

-

Sheet Metal Handling Equipment

Laser Cutting with Gantry Loading and Unloading System of Smart Laser Automation

Read moreRated 0 out of 5 -

Sheet Metal Handling Equipment

Automatic Loading and Unloading Systems for Fiber Laser Cutting Machines

Read moreRated 0 out of 5 -

Sheet Metal Handling Equipment

Automatic Loading and Unloading System for Fiber Laser Cutting Machine

Read moreRated 0 out of 5 -

Sheet Metal Handling Equipment

Automatic Storage System Steel Metal Plate Gantry Loading Unloading Robot Manipulator

Read moreRated 0 out of 5