Automated Steel Plate Storage System

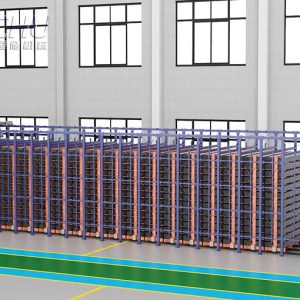

In heavy fabrication, shipbuilding, structural steel, and energy sectors, the handling of large, heavy steel plates presents unique logistical challenges. Traditional storage methods—floor stacking, A-frame racks, or open shelving—not only consume vast amounts of floor space but also expose workers to significant safety hazards and materials to avoidable damage. The Automated Steel Plate Storage System emerges as a purpose-built response to these industry-specific pain points, delivering a seamless fusion of automation, ergonomics, and high-density storage.

Automated Steel Plate Storage System – Precision, Safety, and Space Optimization in One Integrated Solution

In heavy fabrication, shipbuilding, structural steel, and energy sectors, the handling of large, heavy steel plates presents unique logistical challenges. Traditional storage methods—floor stacking, A-frame racks, or open shelving—not only consume vast amounts of floor space but also expose workers to significant safety hazards and materials to avoidable damage. The Automated Steel Plate Storage System emerges as a purpose-built response to these industry-specific pain points, delivering a seamless fusion of automation, ergonomics, and high-density storage.

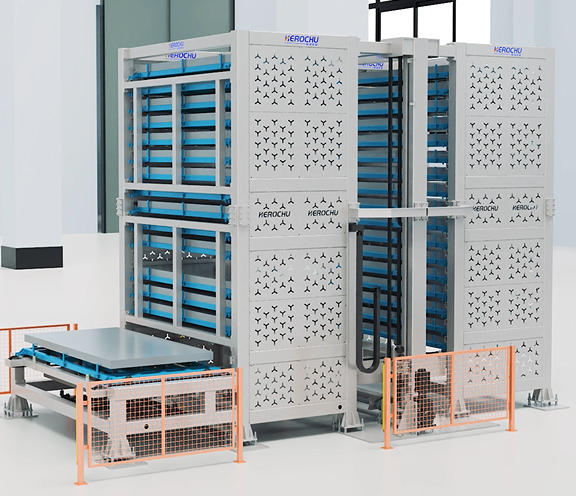

Designed around a dual-tower vertical architecture, this system stores up to 448,800 lbs of steel plate within a remarkably compact 280 sq ft footprint. That’s equivalent to housing over 60 full-sized 6′ x 12′ steel sheets—each weighing several thousand pounds—in less space than a standard parking spot. This spatial efficiency is achieved by leveraging vertical real estate rather than horizontal sprawl, a critical advantage for facilities operating under ceiling height constraints or urban zoning limitations.

The system supports multiple plate dimensions aligned with global industrial standards: 3015mm, 4015mm, 4020mm, 6015mm, and 6020mm configurations ensure compatibility with common cutting and processing equipment. Each of the 8 to 13 storage levels per tower can be engineered for either 3-ton or 5-ton capacity, allowing customization based on material type—whether it’s mild steel, high-strength low-alloy (HSLA), or thick stainless plates used in pressure vessels.

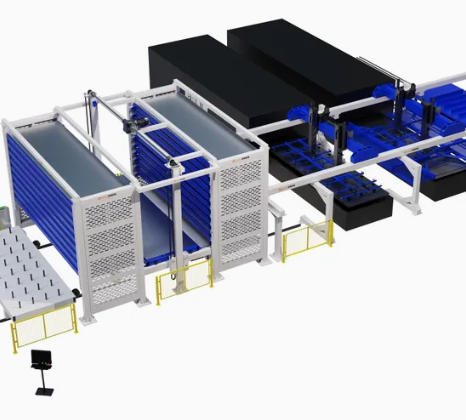

Operationally, the Automated Steel Plate Storage System eliminates the inefficiencies inherent in manual retrieval. Instead of dispatching a forklift operator to navigate narrow aisles or risk toppling unstable stacks, shop floor personnel simply select the required plate via a touchscreen interface. Within seconds, the integrated lift—guided by precision linear rails and powered by a durable chain drive—retrieves the designated plate and delivers it to an ergonomic access point at ground level. With a vertical speed of 9 m/min and in/out speed of 12 m/min, cycle times are minimized, keeping production lines fed without bottlenecking.

One of the most underappreciated benefits of this system is its role in preserving material integrity. Steel plates, especially those with coated, polished, or precision-ground surfaces, are highly susceptible to scratches, dents, and edge deformation during repeated handling. The Automated Steel Plate Storage System mitigates this by using dedicated support frames or optional plate cartridges that cradle each sheet securely, minimizing contact points and preventing slippage during movement. In industries like offshore oil & gas or nuclear fabrication—where even minor surface defects can lead to costly rework or rejection—this level of care translates directly into quality assurance and cost control.

Safety enhancements are equally significant. According to OSHA data, material handling accounts for nearly 25% of all workplace injuries in metalworking facilities. By removing the need for overhead lifting, manual repositioning, or forklift proximity during retrieval, the system drastically reduces exposure to crush injuries, strains, and falls. Additionally, the fully enclosed design prevents unauthorized access and contains potential hazards—such as shifting loads or sharp edges—within a controlled environment.

From a facility management perspective, the system simplifies inventory governance. Every plate entry and exit is automatically recorded, enabling accurate tracking of stock levels, usage trends, and first-in-first-out (FIFO) compliance. Integration with ERP or MRP systems allows for predictive replenishment and digital audit trails, reducing both overstocking and unexpected shortages.

Perhaps most compelling is the system’s rapid return on investment. While the upfront cost may exceed that of static racking, the long-term savings are substantial: reduced floor space requirements lower rent or expansion costs; fewer forklifts mean lower fuel, maintenance, and insurance expenses; decreased scrap rates improve yield; and enhanced worker safety reduces incident-related downtime and liability. Many users report achieving full ROI within 24 to 36 months—a compelling case in capital-intensive industries.

In conclusion, the Automated Steel Plate Storage System is far more than a storage unit—it’s a strategic asset that aligns material logistics with modern manufacturing imperatives: safety, precision, traceability, and space intelligence. For operations serious about competitiveness in an era of lean production and skilled labor shortages, this automated solution offers a clear path forward.

Factory

Hot Selling Machines

-

Heavy Duty Sheet Metal Storage Racks

Intelligent Production Line CNC Automated Storage Rack: Precision Meets Automation

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drawer-Style Sliding Sheet Metal Storage Rack – Efficient & Safe Material Handling

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Design for Steel Plate Storage with Heavy Duty Drawer Type Sheet Metal Rack Storage System

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Rack for Heavy Plates and Molds: Durable, Efficient Storage for Industrial Applications

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drive-In Pallet Rack Alternative: Space-Saving Drawer-Type Sheet Metal Storage with Automated Retrieval Compatibility

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Drawer Type Plate Shelves Warehouse Rack System for Industrial Metal Storage – 3-Ton Capacity per Layer

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Warehouse Storage System: Customizable Solutions for Metal Plate & Industrial Storage

Read moreRated 0 out of 5 -

Automated Storage Systems

Smart Fixed Profile Stereo Warehouse: Cost-Effective Automation for Small to Mid-Sized Fabrication Shops

Read moreRated 0 out of 5

Related products

Related products

-

Automated Storage Systems

Smart Fixed Profile Stereo Warehouse: Cost-Effective Automation for Small to Mid-Sized Fabrication Shops

Read moreRated 0 out of 5 -

Automated Storage Systems

Top-mounted Mobile Metal Tube Rack Storage System

Read moreRated 0 out of 5 -

Automated Storage Systems

Automatic Storage System for Aluminum Profile Up to 8.9 Meter

Read moreRated 0 out of 5