Automated Sheet Metal Loading System

The first step in any sheet metal cutting process—loading the raw material—is deceptively critical. Inconsistency here leads to wasted material, machine downtime, and flawed parts. An Automated sheet Metal loading system eliminates this variability, providing a level of precision, speed, and flexibility that manual operations cannot match. This article focuses on the robotic technology at the heart of this automation and how it empowers manufacturers to achieve new levels of performance.

Precision and Flexibility: Unlocking Potential with an Automated Sheet Metal Loading System

The first step in any sheet metal cutting process—loading the raw material—is deceptively critical. Inconsistency here leads to wasted material, machine downtime, and flawed parts. An Automated sheet Metal loading system eliminates this variability, providing a level of precision, speed, and flexibility that manual operations cannot match. This article focuses on the robotic technology at the heart of this automation and how it empowers manufacturers to achieve new levels of performance.

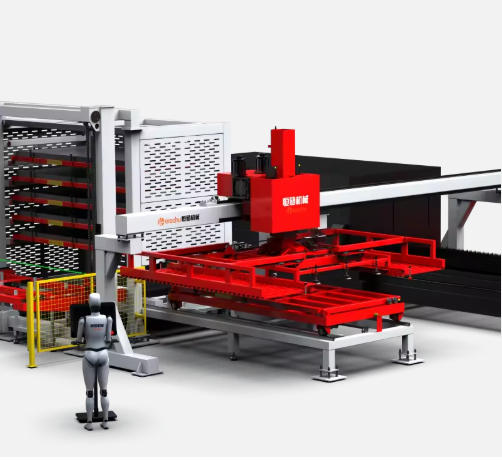

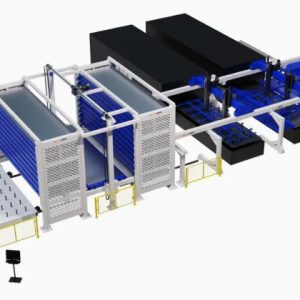

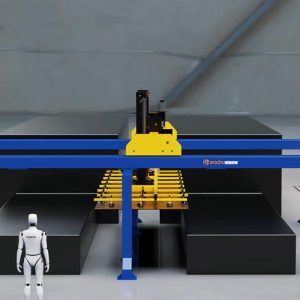

The Robotic Core: Gantry Manipulators in Action

While the storage warehouse provides the inventory, the gantry-mounted loading and unloading manipulators are the system’s dynamic performers. These robots are engineered for the specific demands of handling large-format, heavy metal plates.

The manipulator’s movement along the truss is governed by high-performance servo or variable frequency motors, enabling the fast inlet and outlet speed of 12m/min. This speed is crucial for minimizing the non-cutting time of the associated laser cutting machine. Coupled with a vertical lifting speed of 9m/min, the robot can quickly position itself to pick or place plates from the storage system, the conveyor, or the finished material truck.

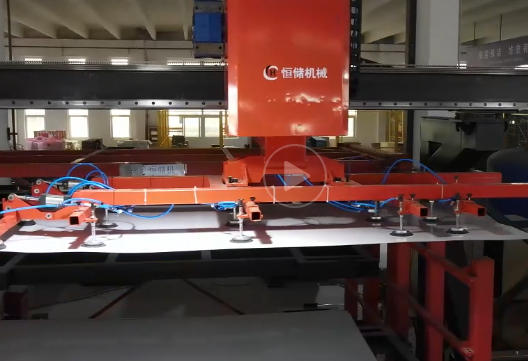

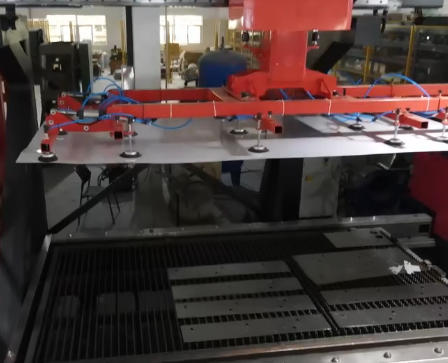

Advanced End-Effector Technology: The Vacuum Suction System

The manipulator’s capability is defined by its end-effector. This system uses a professionally engineered vacuum gripping system, a key differentiator from rudimentary solutions.

-

Safety and Reliability: Utilizing branded vacuum pumps and generators, the system guarantees consistent holding force, critical for the safe handling of expensive and dangerous loads. Redundant safety sensors constantly monitor suction levels, preventing accidental plate drops.

-

Configurable and Intelligent: The suction cups are mounted on adjustable beams, allowing their relative positions to be modified to suit different plate sizes and center-of-gravity requirements. Critically, each suction cup has an independent control switch. This means the controller can activate only the cups needed for a specific plate, conserving energy and allowing the system to handle unusually shaped or sized remnants.

-

The 90-Degree Advantage: The integrated pneumatic rotating mechanism is a game-changer for flexibility. The ability to rotate the plate 90 degrees automatically means the system can feed a laser cutter in either orientation without any manual intervention. This allows for optimal nesting on the cutting bed—orienting parts to maximize material yield and reduce scrap—which is a direct driver of cost savings.

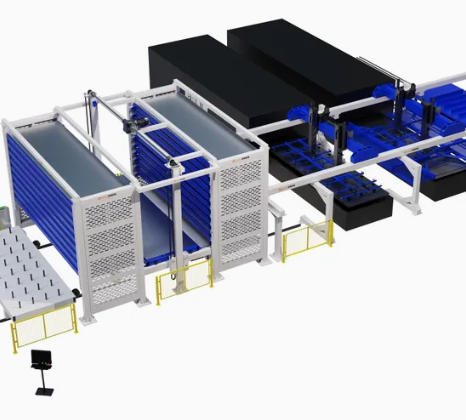

Seamless Integration into the Production Cell

This Automatic Storage System Steel Metal Plate Gantry Loading Unloading Robot Manipulator doesn’t operate in isolation. It is the critical link in an automatic production unit composed of a laser cutting machine. The system is managed by a sophisticated PLC that communicates directly with the laser cutter’s CNC.

-

The laser cutter signals it is ready for a new plate.

-

The PLC instructs the warehouse to deliver the next specified blank to the pickup station.

-

The loading manipulator collects the plate, rotates it to the programmed orientation, and places it with millimeter precision onto the laser cutting bed.

-

Once cutting is complete, the unloading manipulator (or the same unit in a dual-function design) removes the skeleton and cut parts, transferring them to the double-layer finished material truck for sorting and onward processing.

This closed-loop automation creates a continuous workflow, dramatically increasing the laser cutter’s utilization rate.

Tangible Gains in Productivity and Quality

The implementation of this automated loading system directly addresses core manufacturing metrics:

-

Faster Job Changeovers: Automated plate loading and unloading is significantly faster than manual methods, reducing machine idle time between jobs. This allows for more, smaller batches to be run economically.

-

Uncompromising Repeatability: The robotic manipulator places every plate in the exact same position with high repeatability. This eliminates variations in the cut origin, ensuring part consistency across every job and reducing quality inspection time.

-

Enabled Lights-Out Production: The reliability and unattended operation capability of this system are key enablers for extended unmanned shifts. Production can continue safely through breaks, nights, and weekends, multiplying the return on investment for both the loader and the laser cutter.

-

Reduced Direct Labor: One operator can now manage multiple laser cutting cells, as their role shifts from physical labor to supervision, programming, and part sorting.

Conclusion

An Automated Sheet Metal Loading System is the epitome of precision manufacturing. It replaces the most variable and physically taxing part of the cutting process with relentless, accurate, and intelligent automation. By focusing on the advanced capabilities of the gantry robot manipulator—its speed, configurable gripping, and rotational flexibility—this system unlocks the full potential of modern laser cutting equipment. For shops seeking to improve part quality, maximize material yield, and push their productivity into new realms, this technology is the essential next step.

Factory

Hot Selling Machines

-

Heavy Duty Sheet Metal Storage Racks

Intelligent Production Line CNC Automated Storage Rack: Precision Meets Automation

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drawer-Style Sliding Sheet Metal Storage Rack – Efficient & Safe Material Handling

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Design for Steel Plate Storage with Heavy Duty Drawer Type Sheet Metal Rack Storage System

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Rack for Heavy Plates and Molds: Durable, Efficient Storage for Industrial Applications

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drive-In Pallet Rack Alternative: Space-Saving Drawer-Type Sheet Metal Storage with Automated Retrieval Compatibility

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Drawer Type Plate Shelves Warehouse Rack System for Industrial Metal Storage – 3-Ton Capacity per Layer

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Warehouse Storage System: Customizable Solutions for Metal Plate & Industrial Storage

Read moreRated 0 out of 5 -

Automated Storage Systems

Smart Fixed Profile Stereo Warehouse: Cost-Effective Automation for Small to Mid-Sized Fabrication Shops

Read moreRated 0 out of 5

Related products

Related products

-

Sheet Metal Handling Equipment

Gantry Robot Auto Load System for Laser Cutter

Read moreRated 0 out of 5 -

Sheet Metal Handling Equipment

Automatic Loading and Unloading System for Fiber Laser Cutting Machine

Read moreRated 0 out of 5 -

Sheet Metal Handling Equipment

Automatic Storage System Steel Metal Plate Gantry Loading Unloading Robot Manipulator

Read moreRated 0 out of 5 -

Sheet Metal Handling Equipment

Steel Plate Material Handling Equipment for Modern Manufacturing

Read moreRated 0 out of 5