Metal Plate Scrap Rack

In heavy industrial settings where large metal plates are processed, the accumulation of scrap and remnant pieces is inevitable. These pieces, though smaller than full sheets, are often too substantial to discard and can be reused in various applications. However, storing them haphazardly on floors or in piles leads to disorganization, safety risks, and material waste. The Metal Plate Scrap Rack is a heavy-duty vertical storage system designed to address these issues head-on, offering a structured, efficient, and safe solution for managing metal plate residuals.

Metal Plate Scrap Rack: Streamline Your Workshop with Heavy-Duty Vertical Storage

In heavy industrial settings where large metal plates are processed, the accumulation of scrap and remnant pieces is inevitable. These pieces, though smaller than full sheets, are often too substantial to discard and can be reused in various applications. However, storing them haphazardly on floors or in piles leads to disorganization, safety risks, and material waste. The Metal Plate Scrap Rack is a heavy-duty vertical storage system designed to address these issues head-on, offering a structured, efficient, and safe solution for managing metal plate residuals.

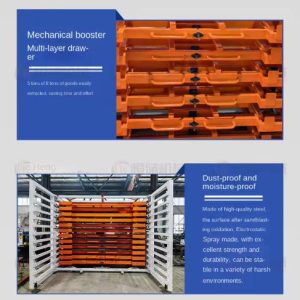

This rack is built for strength and durability, with a loading capacity of 1 ton per single layer. It comes in standard configurations like the HC-V2010-15 for plates up to 2000x1000mm and the HC-V3015-15 for those up to 3000x1500mm, each with 15 layers. The adjustable partition height of 50mm offers flexibility for storing plates of different thicknesses. External dimensions are optimized to save space; for instance, the HC-V2513-15 model measures 2700x2955x1700mm, providing ample storage while maintaining a narrow profile. The key feature is the pull-out drawer system, where each drawer extends fully outside the rack frame, ensuring 100% accessibility.

The benefits of this design are manifold. First, it ensures direct access to any desired metal plate without the need to move other sheets. This is facilitated by the browsing function, which allows users to sift through sheets while they remain securely in place. The drawers are equipped with wheels for smooth movement and non-skid strips to prevent shifting, thereby safeguarding the plates from damage during handling. This protection is crucial for maintaining the integrity and usability of expensive materials like stainless steel or aluminum.

Operational efficiency sees a remarkable boost. With all plates stored vertically and clearly visible, inventory management becomes straightforward, reducing the time spent searching for specific scraps. The need for only one operator to handle retrieval or storage minimizes labor costs and physical strain. The compact nature of the system means it can be installed close to processing machines, enabling just-in-time access and reducing downtime. By solving the problem of disorderly placement, this rack unifies storage into a clean, tidy system that enhances overall workshop safety and productivity. Customizable to specific industry requirements, it is an indispensable tool for any facility looking to optimize space, protect materials, and streamline operations.

Factory

Hot Selling Machines

-

Heavy Duty Sheet Metal Storage Racks

Intelligent Production Line CNC Automated Storage Rack: Precision Meets Automation

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drawer-Style Sliding Sheet Metal Storage Rack – Efficient & Safe Material Handling

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Design for Steel Plate Storage with Heavy Duty Drawer Type Sheet Metal Rack Storage System

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Rack for Heavy Plates and Molds: Durable, Efficient Storage for Industrial Applications

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drive-In Pallet Rack Alternative: Space-Saving Drawer-Type Sheet Metal Storage with Automated Retrieval Compatibility

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Drawer Type Plate Shelves Warehouse Rack System for Industrial Metal Storage – 3-Ton Capacity per Layer

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Warehouse Storage System: Customizable Solutions for Metal Plate & Industrial Storage

Read moreRated 0 out of 5 -

Automated Storage Systems

Smart Fixed Profile Stereo Warehouse: Cost-Effective Automation for Small to Mid-Sized Fabrication Shops

Read moreRated 0 out of 5

Related products

Related products

-

Heavy Duty Sheet Metal Storage Racks

Industrial Multi-Layer Sheet Metal Storage Rack

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

High-Density Sheet Metal Shelf Warehouse Solution

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Roll Out Drawer Storage Rack – The End of “Where’s That Sheet?”

Read moreRated 0 out of 5