In the fast-paced world of steel processing and manufacturing, the efficiency of loading and unloading steel plates directly impacts production timelines, labor costs, and overall operational productivity. The Customized Steel Electric Telescopic Automatic Loading and Unloading System emerges as a transformative solution, designed to eliminate manual handling, reduce downtime, and adapt to the unique needs of diverse industrial facilities. Unlike traditional manual or semi-automatic systems, this electric telescopic system leverages advanced technology—including linear guide rails, chain drives, and high-precision control—to automate the entire process of moving steel plates between storage, production lines (such as laser cutting machines), and shipping areas. Whether for small-scale metal fabrication shops or large-scale steel distribution centers, this customized system delivers reliability, speed, and flexibility, making it a cornerstone of modern industrial operations.

What Is the Customized Steel Electric Telescopic Automatic Loading and Unloading System?

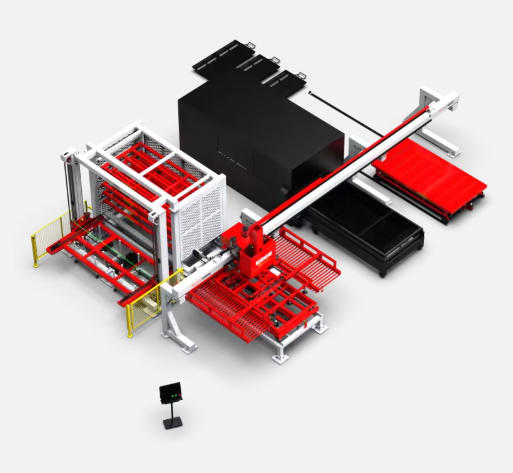

The Customized Steel Electric Telescopic Automatic Loading and Unloading System is a specialized automated material handling solution engineered to transport steel plates of various sizes, weights, and thicknesses with minimal human intervention. At its core, the system features an electric-powered telescopic arm that extends and retracts to reach steel plates in storage racks, production machines, or transport vehicles. This telescopic design allows the system to access plates in tight spaces or deep storage lanes, eliminating the need for forklifts or manual labor to maneuver heavy loads.

Key components of the system include linear guide rails for smooth horizontal movement, chain drives for precise power transmission, and a high-torque electric motor that ensures consistent performance even under heavy loads. The system is fully customizable, with options to adjust the telescopic arm’s length, lifting capacity, movement speed, and integration with other equipment (such as laser cutting machines or AGV transfer systems). Additionally, every unit undergoes rigorous finite element stress analysis using industry-leading software like Simsolid and Ansys. This analysis verifies the system’s structural strength, ensuring it can withstand the daily stress of handling steel plates weighing up to 6 tons per unit—meeting or exceeding the specific needs of each customer.

Core Features of the Customized Steel Electric Telescopic System

- Electric Telescopic Design for Versatile Access: The system’s standout feature is its electric telescopic arm, which can be customized to extend to lengths suitable for different storage configurations. For example, facilities storing 6020mm (6m x 2m) steel plates can opt for a longer telescopic arm, while those handling smaller 3015mm (3m x 1.5m) plates can use a more compact design. This versatility allows the system to access plates in deep storage racks, narrow production lanes, or even stacked pallets, reducing the need for additional space or equipment. The telescopic movement is powered by a high-efficiency electric motor, ensuring smooth, quiet operation and eliminating the emissions associated with diesel-powered forklifts.

- Linear Guide Rails & Chain Drive for Precision: To ensure accurate and consistent movement, the system uses linear guide rails for horizontal travel and chain drives for both horizontal and vertical adjustments. Linear guide rails minimize friction, allowing the telescopic arm to move at speeds of up to 12m/min (inlet and outlet speed) without wobbling or shifting—critical for handling delicate or thin steel plates that could bend or scratch if moved unevenly. The chain drive system, meanwhile, provides reliable power transmission, ensuring the telescopic arm can lift and lower heavy plates (up to 6 tons) with precise control. This combination of components reduces the risk of material damage and ensures the system operates at peak efficiency even during long production shifts.

- High-Speed Operation to Reduce Downtime: Time is a valuable resource in industrial settings, and this system is designed to minimize downtime with its fast movement speeds. The vertical lifting speed reaches 9m/min, allowing the system to quickly raise or lower steel plates between different levels of storage racks or production machines. The inlet and outlet speed—12m/min—ensures that plates are moved from storage to production lines (or vice versa) in a matter of seconds, not minutes. For example, a laser cutting machine that previously waited 5 minutes for a manual load of steel plates can now receive a new plate in under 30 seconds with this automated system. This speed translates to higher production output, as machines spend less time idle and more time processing materials.

- Full Customization for Specific Needs: No two industrial facilities are the same, and this system is built to adapt to unique requirements. Customers can customize multiple parameters, including:

- Load Capacity: Single-unit lifting capacity ranges from 1 ton to 6 tons, making the system suitable for thin steel sheets (lightweight) and thick, heavy plates (such as those used in construction or heavy machinery).

- Size Compatibility: The system can handle steel plates of standard sizes like 3015mm, 4015mm, 4020mm, 6015mm, and 6020mm, with custom sizes available for non-standard plates.

- Color: The system’s exterior can be painted in custom colors to match facility aesthetics or safety protocols (e.g., high-visibility yellow for areas with heavy foot traffic).

- Integration: The system can be seamlessly integrated with laser cutting machines, AGV transfer systems, or warehouse management software (WMS), creating a fully connected material handling ecosystem.

- Rigorous Strength Verification via Finite Element Analysis: Before deployment, every Customized Steel Electric Telescopic System undergoes finite element stress analysis using Simsolid and Ansys. This process simulates real-world conditions—such as lifting 6-ton plates, operating at maximum speed, or enduring temperature fluctuations—to identify potential weak points in the system’s structure. Engineers use the results to adjust components (e.g., reinforcing the telescopic arm with thicker steel or upgrading the chain drive) until the system meets strict strength standards. This verification ensures the system is durable, reliable, and safe for long-term use, reducing the risk of breakdowns or accidents.

Key Benefits of Implementing the System

- Eliminates Manual Labor & Reduces Safety Risks: Manual handling of steel plates is one of the most dangerous tasks in industrial settings, with risks of back injuries, crush accidents, or material drops. This automated system removes the need for workers to lift, push, or guide heavy plates, significantly reducing workplace injuries. For example, a facility that previously required two workers to manually load a 3-ton steel plate onto a laser cutter can now complete the task automatically, with zero human contact. Additionally, the system’s built-in safety features—such as emergency stop buttons, overload sensors, and collision detection—further protect workers and equipment.

- Boosts Production Efficiency & Reduces Downtime: By automating loading and unloading, the system cuts down on the time production machines spend idle. Laser cutting machines, for instance, can operate continuously, as the system delivers new plates and removes finished ones without waiting for manual intervention. This continuous operation can increase production output by 30% or more, depending on the facility’s workflow. The system also reduces downtime caused by human error—such as misaligned plates that jam production machines or damaged materials from improper handling. With precise movement and consistent loading, the system ensures production runs smoothly, even during high-volume periods.

- Seamless Integration with Existing Production Lines: The Customized Steel Electric Telescopic System is designed to work with a wide range of industrial equipment, making it easy to integrate into existing workflows. For facilities with laser cutting machines, the system can be programmed to deliver plates directly to the machine’s input table, then remove cut pieces to a storage area—creating a “lights-out” production loop. It can also connect to AGV transfer systems, allowing steel plates to be moved between storage warehouses and production lines without manual oversight. This integration eliminates bottlenecks in material flow, as plates move from storage to production to shipping in a continuous, automated stream.

- Cost Savings Over Long-Term Use: While the initial investment in an automated system may be higher than traditional manual methods, the long-term cost savings are substantial. The system reduces labor costs by eliminating the need for dedicated workers to handle loading and unloading. For example, a facility with three manual material handlers (earning 25perhour)cansaveover150,000 annually by replacing manual labor with this automated system. Additionally, the system reduces material waste by minimizing damage to steel plates—scratching, bending, or denting—which can cost facilities thousands of dollars per year in discarded materials. The system’s durable design, backed by finite element analysis, also reduces maintenance costs, as it requires fewer repairs than manual or semi-automatic equipment.

- Compliance with Industry Safety & Quality Standards: Every system is built to meet global industrial standards for safety and quality, including OSHA (Occupational Safety and Health Administration) guidelines for material handling and ISO (International Organization for Standardization) standards for automated equipment. The finite element analysis using Simsolid and Ansys ensures the system’s structural integrity, while features like overload sensors and emergency stops prevent accidents. Additionally, the system’s precise operation helps facilities maintain consistent quality in their steel processing—critical for industries like automotive manufacturing or aerospace, where even minor material defects can lead to product failures.

Technical Specifications of the Customized Steel Electric Telescopic System

To provide clarity on the system’s capabilities, below is a breakdown of standard technical specifications—with all parameters fully customizable to meet customer needs:

| Specification | Standard Range | Customization Options |

| Steel Plate Size Compatibility | 3015mm (3m x 1.5m) to 6020mm (6m x 2m) | Non-standard sizes (e.g., 2015mm, 5020mm) available upon request |

| Load Capacity per Unit | 3T to 5T | 1T to 6T (based on customer’s heavy-duty needs) |

| Movement Mode | Linear guide rail + chain | Enhanced linear rails for faster speeds or heavier loads |

| Transmission Mode | Chain drive | Gear-driven options for high-torque applications |

| Vertical Lifting Speed | 9m/min | 6m/min to 12m/min (adjustable for delicate or heavy plates) |

| Inlet/Outlet Speed | 12m/min | 8m/min to 15m/min (customizable for production line pace) |

| Steel Plate Support | Standard metal brackets | Custom support pads (e.g., rubber-coated for scratch prevention) |

| Power Source | 380V/3-phase electric | 220V/1-phase or 480V/3-phase options for regional compatibility |

| Control System | PLC (Programmable Logic Controller) with touchscreen | Integration with warehouse management software (WMS) or MES (Manufacturing Execution System) |

Applications of the Customized Steel Electric Telescopic System

This versatile system is ideal for a wide range of industries and applications where efficient, safe, and automated steel plate handling is critical:

- Laser Cutting & Metal Fabrication Shops: Laser cutting machines require precise, fast loading of steel plates to maintain production efficiency. This system integrates seamlessly with laser cutters, delivering plates to the machine’s bed and removing cut parts—reducing idle time and ensuring consistent cutting quality. For shops handling high volumes of orders, the system’s speed (12m/min inlet/outlet) ensures quick turnaround times for customers.

- Steel Distribution Centers: Distribution centers that store and ship large quantities of steel plates benefit from the system’s ability to automate loading onto trucks or railcars. The telescopic design allows the system to reach into deep storage racks to retrieve plates, while the high load capacity (up to 6T) handles even the heaviest shipments. Integration with RFID tracking (via “one item, one code” management) also ensures accurate inventory control, reducing the risk of shipping errors.

- Automotive Manufacturing Plants: Automotive plants use steel plates to produce car bodies, frames, and components. The system’s precision and speed make it ideal for feeding plates to stamping machines or assembly lines, where even small delays can disrupt production. The system’s customization options—such as rubber-coated support pads—also protect delicate steel surfaces from scratches, ensuring the quality of automotive parts.

- Heavy Machinery Production Facilities: Facilities manufacturing construction equipment, agricultural machinery, or industrial pumps rely on thick, heavy steel plates. The system’s 6T load capacity and robust chain drive make it capable of handling these heavy loads, while the linear guide rails ensure smooth movement to prevent damage. The system’s integration with AGVs also allows plates to be moved between different production stages (e.g., welding, painting) without manual intervention.

- Aerospace Component Suppliers: Aerospace suppliers require ultra-precise handling of steel plates to meet strict quality standards. The system’s finite element-verified strength ensures it can handle lightweight yet high-strength aerospace-grade steel without bending or warping. The high-precision control system also ensures plates are positioned with millimeter accuracy—critical for producing components like aircraft frames or engine parts.

Why Choose the Customized Steel Electric Telescopic Automatic Loading and Unloading System?

In a market flooded with generic material handling solutions, this customized system stands out for three key reasons:

- Tailored to Your Needs: Unlike off-the-shelf systems that require facilities to adapt their operations, this system is designed around your specific requirements. Whether you need to handle 1-ton thin plates or 6-ton thick plates, store 3015mm or 6020mm sizes, or integrate with a laser cutter or AGV, every aspect of the system is customized to fit your workflow.

- Proven Strength & Reliability: The system’s finite element stress analysis using Simsolid and Ansys is not just a formality—it’s a commitment to durability. Every component is tested to ensure it can withstand the daily demands of your facility, reducing the risk of breakdowns and unplanned downtime. This reliability means the system will remain a productive part of your operations for years to come.

- Future-Ready Integration: As industrial facilities adopt Industry 4.0 technologies (such as IoT sensors, real-time monitoring, and AI-driven inventory management), this system is designed to keep up. It can be integrated with IoT sensors for real-time tracking of plate position and weight, as well as WMS software for automated inventory updates. This future-ready design ensures your investment remains valuable as your facility grows and evolves.

Conclusion

The Customized Steel Electric Telescopic Automatic Loading and Unloading System is more than just a material handling tool—it’s a strategic investment in the efficiency, safety, and profitability of your industrial operations. By automating the loading and unloading of steel plates, the system reduces labor costs, minimizes material waste, and speeds up production, all while delivering the flexibility to adapt to your unique needs. Backed by rigorous finite element analysis and built with high-quality components, this system offers the reliability and performance that modern industrial facilities demand.