Roll Out Cantilever Racking & Telesscopic Cantilever Pipe Rack

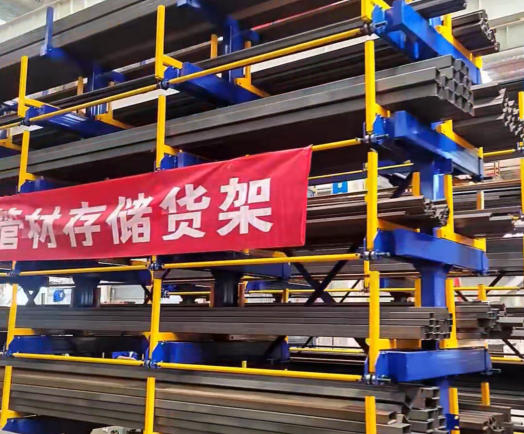

When it comes to storing pipes and other long cylindrical materials, businesses need a storage solution that is not only efficient and space-saving but also ensures easy access and safe handling. Two such solutions that have gained immense popularity in the industrial sector are Roll out cantilever racking and Telesscopic Cantilever Pipe Rack. These two storage systems work together as a dynamic duo, providing businesses with a comprehensive solution for storing pipes of all sizes and lengths.

When it comes to storing pipes and other long cylindrical materials, businesses need a storage solution that is not only efficient and space-saving but also ensures easy access and safe handling. Two such solutions that have gained immense popularity in the industrial sector are Roll out cantilever racking and Telesscopic Cantilever Pipe Rack. These two storage systems work together as a dynamic duo, providing businesses with a comprehensive solution for storing pipes of all sizes and lengths.

Roll out cantilever racking is specifically designed to make the storage and access of long materials such as pipes, bar stock, angle irons, and rollers a breeze. Unlike traditional storage methods where materials are stored in fixed positions, roll out cantilever racking features shelves that can roll out, allowing workers to easily access materials stored at the back of the rack. This eliminates the need to move materials in front to reach the ones behind, saving valuable time and reducing the risk of material damage.

One of the key advantages of roll out cantilever racking is its ability to increase work efficiency. With the roll-out feature, materials can be loaded and unloaded quickly, reducing the time spent on material handling. This is particularly beneficial for businesses that need to move materials frequently, such as manufacturing facilities and construction sites. Additionally, the organized storage provided by roll out cantilever racking makes it easy for workers to quickly identify and locate the pipes they need, further improving productivity.

Space utilization is another major benefit of roll out cantilever racking. By utilizing vertical space and the roll-out feature, businesses can store more pipes in the same amount of space compared to traditional storage methods. The racks can be stacked vertically, and the roll-out shelves allow for deeper storage, meaning that more pipes can be stored on each layer. This not only saves floor space but also reduces the need for additional storage racks, resulting in cost savings.

The solid structure of roll out cantilever racking ensures that it can handle heavy loads, with some models capable of supporting up to 5000kgs per layer. This means that even the heaviest pipes can be stored securely without the risk of rack collapse. Additionally, the racks are designed to be handled by cranes, eliminating the need for wider aisles. This makes it easier to maneuver cranes and other material handling equipment within the warehouse, further improving efficiency.

Complementing roll out cantilever racking is the Telesscopic Cantilever Pipe Rack, a specialized storage system designed specifically for storing pipes. The telescopic feature of this rack allows the arms to extend outward, providing easy access to pipes stored at the back of the rack. This is particularly useful for businesses that store a large number of pipes of different lengths, as it allows for easy sorting and access.

The Telesscopic Cantilever Pipe Rack offers several unique advantages. One of the most notable is its ability to accommodate pipes of various lengths. The telescopic arms can be adjusted to fit different pipe lengths, making it a versatile solution for businesses that deal with a wide range of pipe sizes. Additionally, the rack’s design ensures that pipes are stored securely, reducing the risk of damage during storage and handling.

Another benefit of the Telesscopic Cantilever Pipe Rack is its ease of operation. Many models come with an electrically driven system, powered by a PLC frequency conversion control system. This ensures smooth and precise operation, allowing workers to extend and retract the arms with ease. The PLC control system also provides real-time feedback on the status of the rack, making it easy to monitor and maintain.

When used together, roll out cantilever racking and Telesscopic Cantilever Pipe Rack provide a comprehensive storage solution for pipes. Roll out cantilever racking is ideal for storing pipes that need to be accessed frequently, as the roll-out shelves allow for quick and easy access. The Telesscopic Cantilever Pipe Rack, on the other hand, is perfect for storing pipes of different lengths, as the telescopic arms can be adjusted to fit each pipe’s specific length.

To illustrate the capabilities of these two storage systems, let’s take a look at some standard models. For roll out cantilever racking, the HC-G6053S model is a single-unit rack with a storage sheet size of 6000mm, a loading capacity of 2 tons per layer, and 3+1 layers, resulting in a total loading capacity of 8 tons per rack. The HC-G6053D, a double-unit rack, offers a loading capacity of 3 tons per layer and 4+1 layers, with a total loading capacity of 25 tons per rack. For larger storage needs, the HC-G9055S and HC-G9055D models provide storage sheet sizes of 9000mm and 12000mm, with loading capacities of 5 tons and 6 tons per layer, and total loading capacities of 35 tons and 42 tons per rack.

For the Telesscopic Cantilever Pipe Rack, similar models are available, with customized options to meet specific pipe storage needs. The racks can be designed to accommodate pipes of different diameters and lengths, with adjustable telescopic arms to ensure a perfect fit. The loading capacity of these racks is also impressive, with some models capable of supporting up to 5000kgs per layer, ensuring that even the heaviest pipes can be stored safely.

In conclusion, Roll out cantilever racking and Telesscopic Cantilever Pipe Rack are two essential storage solutions for businesses dealing with pipes and other long cylindrical materials. They work together to provide a efficient, space-saving, and safe storage solution that helps to improve work efficiency, reduce costs, and enhance workplace safety. By investing in these two storage systems, businesses can streamline their pipe storage operations and achieve long-term success in today’s competitive industrial market.

Factory

Hot Selling Machines

-

Heavy Duty Sheet Metal Storage Racks

Intelligent Production Line CNC Automated Storage Rack: Precision Meets Automation

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drawer-Style Sliding Sheet Metal Storage Rack – Efficient & Safe Material Handling

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Design for Steel Plate Storage with Heavy Duty Drawer Type Sheet Metal Rack Storage System

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Rack for Heavy Plates and Molds: Durable, Efficient Storage for Industrial Applications

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drive-In Pallet Rack Alternative: Space-Saving Drawer-Type Sheet Metal Storage with Automated Retrieval Compatibility

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Drawer Type Plate Shelves Warehouse Rack System for Industrial Metal Storage – 3-Ton Capacity per Layer

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Warehouse Storage System: Customizable Solutions for Metal Plate & Industrial Storage

Read moreRated 0 out of 5 -

Automated Storage Systems

Smart Fixed Profile Stereo Warehouse: Cost-Effective Automation for Small to Mid-Sized Fabrication Shops

Read moreRated 0 out of 5

Related products

Related products

-

Heavy Duty Cantilever Racking System

Roll-Out Telescopic Cantilever Rack for Streamlined Operations

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Telescopic Cantilever Pipe Racks for Modern Industrial Warehousing

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

High-Capacity Electric Telescopic Cantilever Shelves for Efficient Storage

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Hand-Operated Telescoping Cantilever Shelving – Flexible, Adaptable Warehouse Storage

Read moreRated 0 out of 5