Drawer-Type Sheet Metal Racks for Modern Manufacturing Facilities

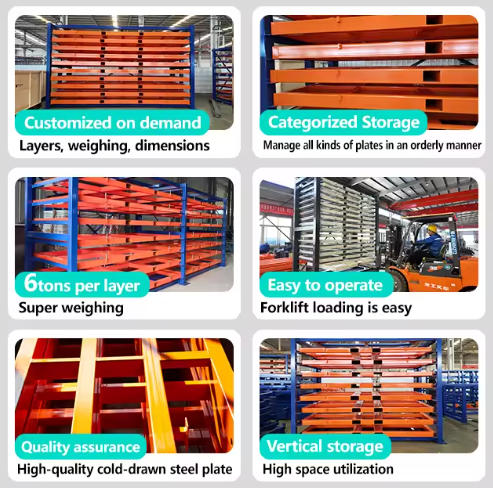

Industrial storage of sheet metal presents a fundamental challenge that impacts production efficiency, workplace safety, and material integrity. Traditional stacking methods create inaccessible inventories, cause surface damage, and consume valuable floor space. The drawer-type sheet metal rack directly addresses these operational pain points through an engineered solution that combines heavy-duty construction with intelligent accessibility.

The Ultimate Guide to Drawer-Type Sheet Metal Racks for Modern Manufacturing Facilities

Industrial storage of sheet metal presents a fundamental challenge that impacts production efficiency, workplace safety, and material integrity. Traditional stacking methods create inaccessible inventories, cause surface damage, and consume valuable floor space. The drawer-type sheet metal rack directly addresses these operational pain points through an engineered solution that combines heavy-duty construction with intelligent accessibility.

Core Design Philosophy

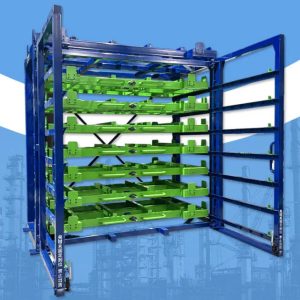

At its foundation, the drawer-type sheet metal rack employs a structural metal frame supporting independent drawer units on each level. These aren’t simple sliding shelves—they’re precision-engineered systems utilizing either roller mechanisms or heavy-duty slide rails designed specifically for industrial loads. The distinction matters. Standard shelving collapses under the weight of steel sheets; these racks accommodate up to 20 tons per individual layer. A twelve-meter extended design isn’t merely about vertical height—it’s about creating a storage ecosystem where materials remain accessible without vertical stacking.

Manual and Electric Operation Modes

Operational flexibility defines the user experience. For manual handling, the system requires minimal physical effort—a controlled hand crank movement sets the drawer in motion, gliding smoothly along its rails without jamming or slipping. This mechanical advantage proves crucial when operators retrieve materials multiple times per shift. For facilities prioritizing automation, electric operation provides fingertip control through a single remote button. This dual-mode capability means the rack adapts to your workflow rather than forcing workflow changes to accommodate equipment limitations.

Load Capacity Engineering

The specification table reveals the engineering depth:

-

HC-B3015-63: 3-ton capacity per layer, 3×1.5m surface area, six customizable layers

-

HC-B4015-65: 5-ton capacity, 4×1.5m dimensions, six layers

-

HC-B4020-68: 8-ton capacity, 4×2m surface area, six layers

-

HC-B6020-610: 10-ton capacity, 6×2m surface area, six layers

These aren’t theoretical maximums—they’re tested ratings with built-in safety margins. The 20-ton ultra-strong capacity mentioned for specialized configurations comes from reinforced guide rails and frame structures that distribute weight across multiple load points. This prevents the rail deformation common in inferior systems.

Dimensional Intelligence

Overall dimensions show careful planning: 3505×2280×2000mm for smaller units scaling up to 6505×2280×2500mm for maximum capacity models. The depth remains consistent at 2280mm—an ergonomic sweet spot allowing operator access without overreach. Height varies based on vertical space requirements. This standardization simplifies facility planning while the customizable length and width accommodate specific material dimensions.

Workshop Transformation Benefits

Material retrieval efficiency improves dramatically when operators access specific sheets without moving entire stacks. Consider a typical scenario: a fabrication shop stores stainless steel, aluminum, and mild steel sheets for different jobs. With categorized drawer storage, a worker pulls the designated drawer, retrieves the required sheet, and closes it within thirty seconds. The same operation using traditional methods requires locating the correct stack, shifting materials above it, extracting the sheet (often with forklift assistance), then restacking—consuming fifteen to twenty minutes and involving multiple personnel.

Surface damage reduction provides another measurable benefit. Stacked sheets develop scratches, dents, and pressure marks from the weight above them. Drawer storage eliminates vertical pressure entirely. Each sheet lies flat on its drawer surface, protected from contact with other materials. For high-value metals like brushed aluminum or pre-painted steel, this protection translates directly into reduced waste and improved product quality.

Floor space optimization creates secondary advantages. Consolidating sheet storage into vertical drawer units frees floor area for production equipment or workflow expansion. A facility storing 100 tons of sheet metal traditionally requires approximately 400 square meters of floor space with access aisles. Drawer-type sheet metal racks reduce this footprint by 60-70% while improving material accessibility.

Implementation Considerations

Installation requires evaluating floor load capacity. The HC-B6020-610 model, fully loaded with 10 tons per layer across six layers, concentrates 60 tons in a 6.5×2.3 meter footprint. This demands reinforced flooring in older facilities. Electrical requirements for motorized units remain minimal—standard 220V single-phase power suffices, though three-phase connections optimize performance for continuous operation.

Integration with existing material handling equipment enhances utility. While the system eliminates forklift dependency for basic retrieval, overhead cranes and gantry systems work seamlessly with extended drawers for heavy plate manipulation. The design accommodates this workflow through reinforced drawer fronts that support loads during partial extension.

Maintenance and Longevity

The heavy-duty slide rails require quarterly inspection of lubrication points and alignment. Quality systems use sealed bearing rollers requiring minimal maintenance beyond visual checks. Frame integrity inspections occur annually, focusing on weld points and bolt tension. Properly maintained units operate reliably for fifteen to twenty years in demanding environments.

Return on Investment Reality

Most facilities achieve ROI within eighteen to twenty-four months through combined savings: labor reduction (40-50% fewer man-hours for material handling), damage reduction (15-20% decrease in sheet waste), and space optimization (avoiding facility expansion costs). The electric operation option adds approximately 15% to initial cost but delivers additional savings in high-throughput environments.

Factory

Hot Selling Machines

-

Heavy Duty Sheet Metal Storage Racks

Intelligent Production Line CNC Automated Storage Rack: Precision Meets Automation

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drawer-Style Sliding Sheet Metal Storage Rack – Efficient & Safe Material Handling

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Design for Steel Plate Storage with Heavy Duty Drawer Type Sheet Metal Rack Storage System

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Rack for Heavy Plates and Molds: Durable, Efficient Storage for Industrial Applications

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drive-In Pallet Rack Alternative: Space-Saving Drawer-Type Sheet Metal Storage with Automated Retrieval Compatibility

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Drawer Type Plate Shelves Warehouse Rack System for Industrial Metal Storage – 3-Ton Capacity per Layer

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Warehouse Storage System: Customizable Solutions for Metal Plate & Industrial Storage

Read moreRated 0 out of 5 -

Automated Storage Systems

Smart Fixed Profile Stereo Warehouse: Cost-Effective Automation for Small to Mid-Sized Fabrication Shops

Read moreRated 0 out of 5

Related products

Related products

-

Heavy Duty Sheet Metal Storage Racks

High-Density Heavy Duty Steel Plate Shelving Rack

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Industrial Multi-Layer Sheet Metal Storage Rack

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy Duty Shelves Built for Sheet Metal—Not Afterthoughts

Read moreRated 0 out of 5