Facility managers evaluating storage investments must quantify operational costs against capital expenditure. Roll-out sheet metal racks demonstrate clear financial advantages over conventional stacking, but understanding the complete cost picture requires examining direct and indirect savings.

Hidden Costs of Traditional Stacking

Sheet metal storage using floor stacking creates expenses beyond obvious floor space usage. Material damage represents the most significant hidden cost. Pressure marks from upper sheets emboss lower layers, rendering them unsuitable for visible applications. Surface scratches occur when workers slide sheets from stacks. Edge damage happens during retrieval attempts. Combined, these issues waste 8-15% of inventory value annually in typical shops.

Labor inefficiency compounds damage costs. Retrieving a single sheet from mid-stack requires:

- Locating the correct stack (5-10 minutes)

- Moving obstructing materials (10-20 minutes)

- Extracting the target sheet (5-15 minutes)

- Restacking removed materials (10-20 minutes)

This 30-65 minute process requires two workers for safety. At $35 per hour fully loaded labor cost, each retrieval costs $35-$76 in wages alone. Facilities performing ten retrievals daily spend $350-$760 daily, $91,000-$197,000 annually, just accessing stored materials.

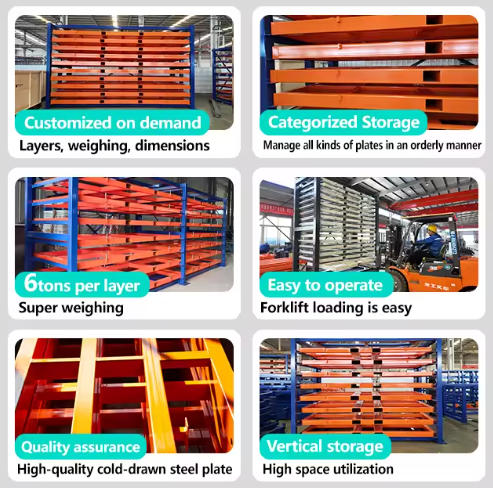

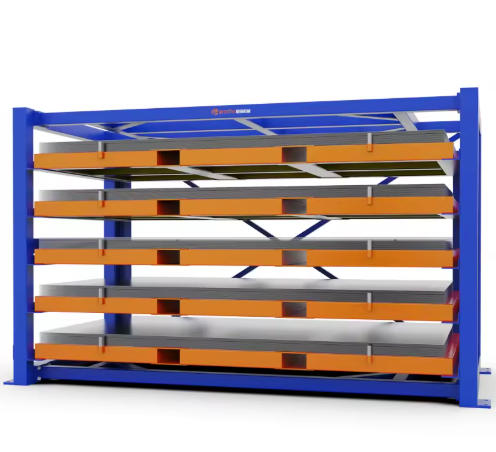

Space utilization inefficiency extends facility costs. Stacked sheet storage with aisle access requires 12-15 square meters per ton of material. Roll-out sheet metal racks reduce this to 4-5 square meters per ton—a 65% space savings. For a facility storing 200 tons, this frees 1,400-2,000 square meters. At typical industrial lease rates of $8-12 per square meter monthly, this represents $134,000-$288,000 annual rent savings or capacity for additional production equipment.

Direct Benefits Quantification

Roll-out sheet metal racks eliminate vertical stacking pressure. Material damage rates drop to under 2%, representing direct inventory savings. For a facility holding $500,000 in sheet metal inventory, reducing waste from 12% to 2% saves $50,000 annually in material costs alone.

Retrieval time reduction delivers immediate labor savings. Operators access materials in 1-3 minutes versus 30-65 minutes—90-95% time reduction. The same facility performing ten daily retrievals now spends $4-$8 daily, reducing annual labor costs from $91,000-$197,000 to $1,040-$2,080. This $89,000-$195,000 annual saving often exceeds the equipment investment cost.

Forklift operation reduction generates secondary savings. Traditional sheet retrieval requires forklift transport from storage to processing area. Drawer systems position materials at or near processing stations, reducing forklift travel by 70-80%. This cuts fuel consumption, tire wear, and maintenance costs while improving facility safety.

ROI Calculation Framework

Initial investment varies by configuration:

- Manual HC-B3015-63: $8,000-$12,000

- Electric HC-B6020-610: $25,000-$35,000

- Complete system with six units and accessories: $60,000-$120,000

Annual savings calculation:

- Material waste reduction: $30,000-$75,000 (typical range)

- Labor cost reduction: $89,000-$195,000

- Space optimization value: $67,000-$144,000 (half the rent savings, as some aisle space remains)

- Equipment wear reduction: $5,000-$10,000

Total annual savings: $191,000-$424,000

Payback period: $120,000 investment ÷ $191,000 annual savings = 0.63 years (7.5 months) to $60,000 investment ÷ $424,000 savings = 0.14 years (1.7 months). Realistic payback periods range from 6-18 months depending on facility size and throughput.

Comparative Performance Metrics

Space efficiency:

- Traditional stacking: 0.08 tons per square meter

- Roll-out racks: 0.25 tons per square meter

- Improvement: 212% density increase

Labor productivity:

- Traditional: 1-2 retrievals per worker hour

- Roll-out: 20-30 retrievals per worker hour

- Improvement: 1,500-2,000%

Material accessibility:

- Traditional: 30-60% of inventory readily accessible

- Roll-out: 95-100% inventory accessible within 3 minutes

- Improvement: 58-233% accessibility gain

Implementation Timeline and Disruption

Installation typically requires 2-3 days per unit, including foundation preparation and anchoring. Facilities can phase implementation, installing one or two units while maintaining traditional storage for remaining inventory. This staged approach eliminates operational disruption while allowing staff training and process adjustment.

Material transfer from old to new storage occurs during normal operations. Teams move materials as needed for production, gradually populating the drawer system. This “pull” migration prevents the chaos of mass transfer while immediately demonstrating efficiency gains to operators.

Integration with Existing Infrastructure

Facilities with overhead cranes integrate roll-out racks seamlessly. The extended drawer positions materials within crane reach, eliminating forklift staging. For shops without cranes, the system’s independence from powered handling equipment becomes a primary advantage—operators manually retrieve sheets up to the per-layer weight limit without equipment rental or fuel costs.

Hand crank and forklift sheet metal storage equipment configurations serve mixed environments. Manual crank handles routine retrievals; forklifts remain available for heavy plate handling exceeding drawer capacity. This hybrid approach optimizes equipment utilization—forklifts handle tasks requiring their capabilities while routine access occurs without tying up expensive equipment.

Long-Term Value Proposition

Asset depreciation benefits apply. Storage equipment qualifies for accelerated depreciation schedules, providing tax advantages. The system’s twenty-year service life delivers value long after ROI realization. Resale value remains strong—well-maintained units retain 40-60% of purchase price after ten years, as the robust construction withstands industrial environments.

Scalability supports business growth. Additional units integrate with existing installations, creating modular storage complexes. Standardized dimensions ensure new units match current inventory management systems. As production expands, storage capacity expands proportionally without facility relocation.

Performance Monitoring Metrics

Successful implementations track:

- Retrieval time per sheet (target: under 3 minutes)

- Material damage incidents (target: under 2%)

- Labor hours dedicated to material handling (target: 50% reduction)

- Floor space utilization per ton stored (target: under 5 square meters)

Monthly performance reviews against these metrics validate investment value and identify optimization opportunities. Facilities achieving these targets typically exceed projected ROI by 15-25%.