Intelligent Sheet Metal Storage System FAQ and Specification Guide

Considering an Intelligent Sheet Metal Storage System is a significant step towards automation. It’s natural to have detailed questions about feasibility, cost, and compatibility. This comprehensive FAQ and specification guide is designed to answer your most pressing questions, clarify key technical details, and help you understand how to move forward with a solution tailored precisely to your factory’s needs. From pricing to integration, we cover the essentials to inform your decision.

Considering an Intelligent Sheet Metal Storage System is a significant step towards automation. It’s natural to have detailed questions about feasibility, cost, and compatibility. This comprehensive FAQ and specification guide is designed to answer your most pressing questions, clarify key technical details, and help you understand how to move forward with a solution tailored precisely to your factory’s needs. From pricing to integration, we cover the essentials to inform your decision.

Frequently Asked Questions (FAQ)

Q: How do we get an accurate price for a sheet metal storage tower?

A: We provide customized automatic sheet metal storage system quotes based on your specific requirements. To give you an accurate price and technical proposal, we need the following details:

-

Material Details: The type of sheets you store (steel, aluminum, etc.), along with the max thickness and max width.

-

Production Integration: What kind of machine do you want to connect? Our automated storage warehouse is highly flexible. It can integrate not only with laser cutting machines, plate shearing machines, and turret punch presses but also with virtually any other sheet metal processing machine.

-

Factory Layout: Providing your available factory site space (length, width, height clearance) is crucial. Our engineering team will design a layout that maximizes your storage density and workflow efficiency within your existing footprint.

Q: Is the system only for laser cutting shops?

A: Absolutely not. While integrating with a Laser Cutting Machine is a common and highly effective application, the system’s utility is far broader. It is an Intelligent Plate Storage Unit Smart Warehouse Rack that can serve as the central hub for various processes:

-

Feeding and retrieving from automated punching centers.

-

Supplying blanks to a robotic press brake cell.

-

Managing inventory for a shearing line.

-

Storing raw materials and finished products for welding or assembly lines.

Its design is flexible independent of manufacturer, meaning it can be adapted to work with equipment from any major brand.

Q: What are the core benefits in simple terms?

A: The benefits are clear and impactful:

-

Saves Space: Utilizes vertical height, freeing up floor space.

-

Saves Time & Labor: Automates material handling to improve manufacturing process.

-

Improves Safety: Removes workers from hazardous material movement.

-

Protects Material: Prevents damage to expensive plates.

-

Improves Management: Offers easy and clear production management through software.

Q: How is the system controlled?

A: It is controlled by a Programmable Logic Controller (PLC) and an intuitive touch-screen Human-Machine Interface (HMI). This allows for classified visual management of plates. For advanced planning, it can also connect to your factory’s MES or ERP system for seamless production scheduling and inventory tracking.

Detailed System Specifications

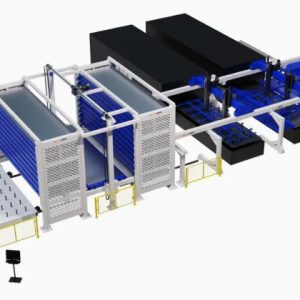

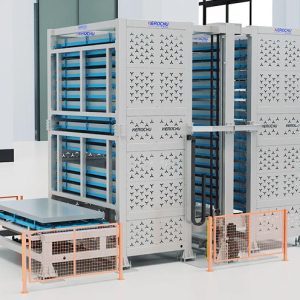

Here is a breakdown of standard specifications for our Automatic Sheet Metal Storage Unit:

-

Functionality: Enables centralized storage of plates, automatic weight detection, automatic warehousing, and automatic retrieval.

-

Standard Compatible Sheet Sizes (mm): 3015, 4015, 4020, 6015, 6020, 6025. Custom sizes are available.

-

Number of Floors (Layers): Configurable, typically ranging from 8 to 13 layers, depending on ceiling height and capacity needs.

-

Load Capacity per Layer: 3 Tons or 5 Tons options, ensuring handling of heavy steel plates.

-

Movement Mechanism: Linear guide rail + chain for smooth, high-precision horizontal movement.

-

Transmission Mode: Chain drive for robust and reliable power transfer.

-

Vertical Lifting Speed: 9 meters per minute for efficient access to all layers.

-

Inlet/Outlet (Horizontal) Speed: 12 meters per minute for fast material transfer.

-

Plate Support: Various optional selection support systems (rollers, forks, padded clamps) are available to suit different material types and prevent damage.

Conclusion

Implementing an Intelligent Sheet Metal Storage System is a customized process, but the principles and benefits are universal. By providing detailed information about your materials, machines, and space, you enable our engineering team to design a solution that will effectively ensure product quality, improve production efficiency, and reduce production costs in your specific operation. This FAQ and spec guide is the first step in exploring how automation can transform your warehouse and production flow.

Factory

Hot Selling Machines

-

Heavy Duty Sheet Metal Storage Racks

Intelligent Production Line CNC Automated Storage Rack: Precision Meets Automation

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drawer-Style Sliding Sheet Metal Storage Rack – Efficient & Safe Material Handling

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Design for Steel Plate Storage with Heavy Duty Drawer Type Sheet Metal Rack Storage System

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Rack for Heavy Plates and Molds: Durable, Efficient Storage for Industrial Applications

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drive-In Pallet Rack Alternative: Space-Saving Drawer-Type Sheet Metal Storage with Automated Retrieval Compatibility

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Drawer Type Plate Shelves Warehouse Rack System for Industrial Metal Storage – 3-Ton Capacity per Layer

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Warehouse Storage System: Customizable Solutions for Metal Plate & Industrial Storage

Read moreRated 0 out of 5 -

Automated Storage Systems

Smart Fixed Profile Stereo Warehouse: Cost-Effective Automation for Small to Mid-Sized Fabrication Shops

Read moreRated 0 out of 5

Related products

Related products

-

Automation Sheet Metal Material Warehouse

Automatic Sheet Metal Storage & Retrieval System (AS/RS) – Automated Loading Unloading Racks

Read moreRated 0 out of 5 -

Automation Sheet Metal Material Warehouse

Metal Sheet Warehouse Rack Solution

Read moreRated 0 out of 5 -

Automation Sheet Metal Material Warehouse

Maximizing Efficiency with Dual-Tower Automated Storage Solutions

Read moreRated 0 out of 5 -

Automation Sheet Metal Material Warehouse

Double-Tower Sheet Material Automated Storage and Retrieval System

Read moreRated 0 out of 5