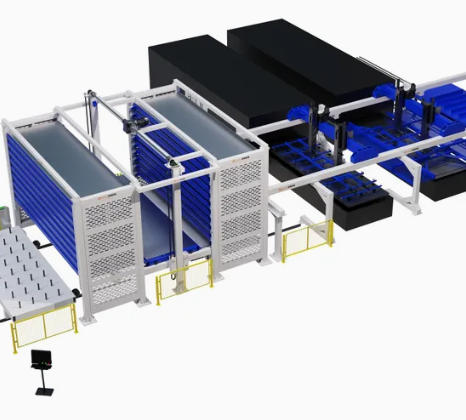

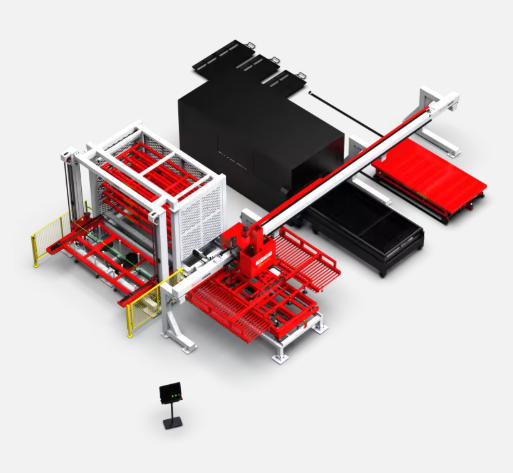

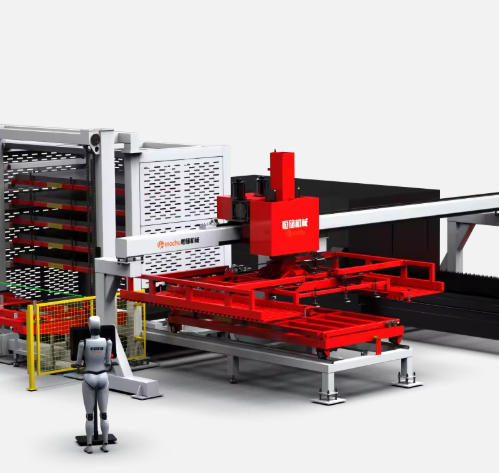

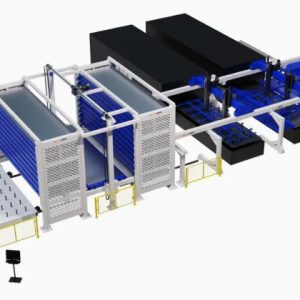

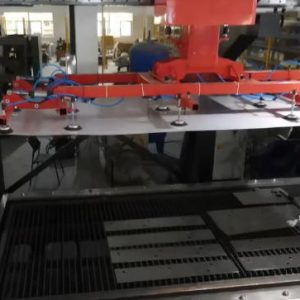

Gantry Loading System for Fiber Laser and Cutting Lines

The Gantry loading system for Fiber laser and cutting lines represents a perfect synergy between advanced material handling and cutting-edge laser technology. This integration offers several distinct advantages

Gantry Loading System for Fiber Laser and Cutting Lines: Optimizing Production

System Integration with Fiber Laser Technology

The Gantry loading system for Fiber laser and cutting lines represents a perfect synergy between advanced material handling and cutting-edge laser technology. This integration offers several distinct advantages:

Enhanced Cutting Precision: The stability of the gantry system allows Fiber lasers to operate at their full potential, delivering clean, accurate cuts even in high-speed operations.

Increased Throughput: By eliminating manual loading and unloading times, production cycles are significantly reduced, leading to higher output rates.

Material Versatility: The system can handle a wide range of materials, from thin gauge sheets to thick stainless steel plates, with equal efficiency.

Improved Safety: Automated material handling reduces operator exposure to potential hazards, creating a safer work environment.

Key Features for Fiber Laser Applications

Adaptive Vacuum Technology: The system features intelligent vacuum control that automatically adjusts based on material type and surface conditions, ensuring optimal grip without causing damage.

Dynamic Load Balancing: Advanced algorithms distribute weight evenly across the gantry structure, preventing overloading and ensuring smooth operation even with heavy materials.

Real-Time Monitoring: Integrated sensors provide continuous feedback on system performance, allowing for immediate adjustments to maintain optimal cutting conditions.

Seamless Integration with Cutting Software: The system works in harmony with CAD/CAM software, enabling precise material positioning based on cutting patterns.

Factory

Hot Selling Machines

-

Heavy Duty Sheet Metal Storage Racks

Intelligent Production Line CNC Automated Storage Rack: Precision Meets Automation

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drawer-Style Sliding Sheet Metal Storage Rack – Efficient & Safe Material Handling

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Design for Steel Plate Storage with Heavy Duty Drawer Type Sheet Metal Rack Storage System

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Rack for Heavy Plates and Molds: Durable, Efficient Storage for Industrial Applications

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drive-In Pallet Rack Alternative: Space-Saving Drawer-Type Sheet Metal Storage with Automated Retrieval Compatibility

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Drawer Type Plate Shelves Warehouse Rack System for Industrial Metal Storage – 3-Ton Capacity per Layer

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Warehouse Storage System: Customizable Solutions for Metal Plate & Industrial Storage

Read moreRated 0 out of 5 -

Automated Storage Systems

Smart Fixed Profile Stereo Warehouse: Cost-Effective Automation for Small to Mid-Sized Fabrication Shops

Read moreRated 0 out of 5

Related products

Related products

-

Sheet Metal Handling Equipment

Innovative Material Handling Solutions: The Servo Swing Arm Manipulator for CNC Operations

Read moreRated 0 out of 5 -

Sheet Metal Handling Equipment

Gantry Robot Auto Load System for Laser Cutter

Read moreRated 0 out of 5