Innovative Heavy-Duty Sheet Material Storage Racks

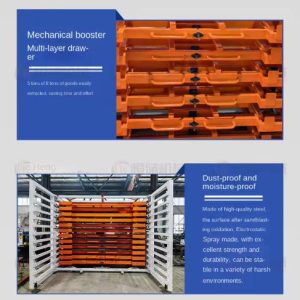

The Heavy-Duty Drawer-Type Sheet Rack is a marvel of modern engineering, designed to provide workers with fingertip control over large-sized plates. This system eliminates the need for cumbersome forklifts or manual lifting, significantly reducing labor intensity and minimizing the risk of material damage. By allowing plates to be pulled out directly, workers can access any sheet with ease, streamlining workflows and enhancing productivity.

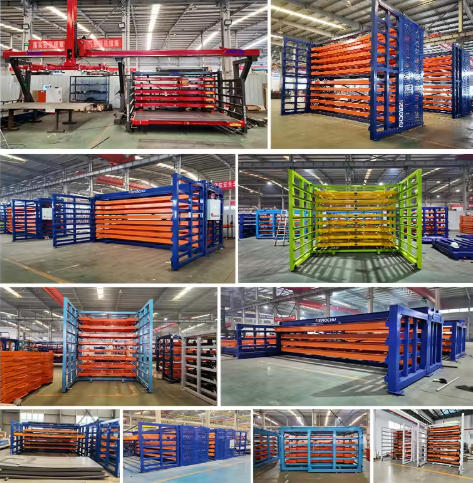

In industries where sheet materials like metal, plastic, or composite plates are central to operations, efficient storage isn’t just about organization—it’s about productivity, safety, and cost-effectiveness. Traditional storage methods often fall short, leading to wasted space, material damage, and operational bottlenecks. Enter the game-changing realm of heavy-duty sheet material storage racks, designed to revolutionize how businesses manage their inventory. This article delves into four advanced storage solutions, each tailored to address specific industrial needs while maximizing space utilization and operational efficiency.

Heavy-Duty Drawer-Type Sheet Rack: Precision Engineering for Direct Access

Overview

The Heavy-Duty Drawer-Type Sheet Rack is a marvel of modern engineering, designed to provide workers with fingertip control over large-sized plates. This system eliminates the need for cumbersome forklifts or manual lifting, significantly reducing labor intensity and minimizing the risk of material damage. By allowing plates to be pulled out directly, workers can access any sheet with ease, streamlining workflows and enhancing productivity.

Key Features

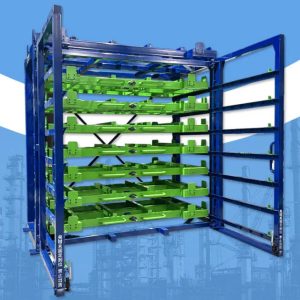

- Fingertip Control: Workers can effortlessly pick and place large-sized plates, reducing physical strain and improving efficiency.

- Space Optimization: The drawer system maximizes space utilization, fitting more sheets into a smaller footprint compared to traditional methods.

- Enhanced Safety: By eliminating the need for heavy machinery in tight spaces, the system reduces the risk of workplace accidents.

- Durability: Constructed from high-strength materials, the rack withstands heavy loads and frequent use, ensuring long-term reliability.

Applications

Ideal for industries such as automotive manufacturing, aerospace, and construction, where large sheets of metal or composite materials are routinely handled. Companies like XYZ Automotive have reported a 30% reduction in material handling time after implementing this system.

Customization Options

Available in various sizes and configurations, the drawer-type sheet rack can be tailored to specific plate dimensions and load requirements. For instance, the HC-B2015-62 model accommodates 2000x150mm plates, while the HB-B3015-65 model is designed for 3000x1500mm sheets.

Factory

Hot Selling Machines

-

Heavy Duty Sheet Metal Storage Racks

Intelligent Production Line CNC Automated Storage Rack: Precision Meets Automation

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drawer-Style Sliding Sheet Metal Storage Rack – Efficient & Safe Material Handling

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Design for Steel Plate Storage with Heavy Duty Drawer Type Sheet Metal Rack Storage System

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Rack for Heavy Plates and Molds: Durable, Efficient Storage for Industrial Applications

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drive-In Pallet Rack Alternative: Space-Saving Drawer-Type Sheet Metal Storage with Automated Retrieval Compatibility

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Drawer Type Plate Shelves Warehouse Rack System for Industrial Metal Storage – 3-Ton Capacity per Layer

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Warehouse Storage System: Customizable Solutions for Metal Plate & Industrial Storage

Read moreRated 0 out of 5 -

Automated Storage Systems

Smart Fixed Profile Stereo Warehouse: Cost-Effective Automation for Small to Mid-Sized Fabrication Shops

Read moreRated 0 out of 5

Related products

Related products

-

Heavy Duty Sheet Metal Storage Racks

Revolutionize Material Handling with Forklift-Compatible Sheet Metal Racks

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

High-Density Sheet Metal Shelf Warehouse Solution

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy Duty Flat Products Storage Racks

Read moreRated 0 out of 5