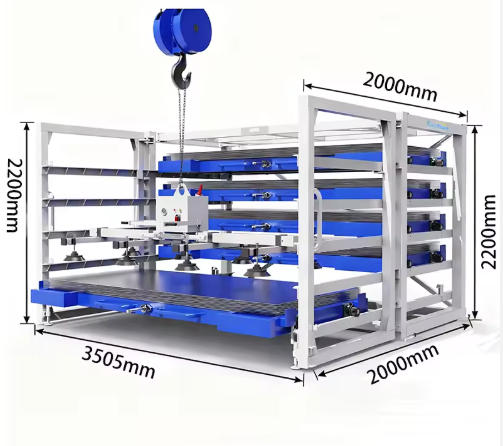

Metal Sheet Forklift Rack

Efficient material handling begins long before the first cut is made on a laser table—it starts with how raw sheet metal is received, stored, and staged for production. The Metal Sheet Forklift Rack addresses this foundational need with a rugged, intelligent design that replaces outdated, inefficient practices like floor stacking or disposable wooden pallets.Built to withstand the daily rigors of heavy industrial use, this rack features a reinforced pallet structure capable of supporting up to 5 metric tons of sheet material. Each unit is constructed from high-strength steel with welded joints and anti-slip surfaces, ensuring sheets remain stable during lifting, transport, and storage. Unlike wood—which splinters, warps, and absorbs moisture—the metal rack delivers consistent performance year after year, even in humid or outdoor-adjacent environments.

Metal Sheet Forklift Rack – Engineered for Durability, Safety, and Space Optimization

Efficient material handling begins long before the first cut is made on a laser table—it starts with how raw sheet metal is received, stored, and staged for production. The Metal Sheet Forklift Rack addresses this foundational need with a rugged, intelligent design that replaces outdated, inefficient practices like floor stacking or disposable wooden pallets.

Built to withstand the daily rigors of heavy industrial use, this rack features a reinforced pallet structure capable of supporting up to 5 metric tons of sheet material. Each unit is constructed from high-strength steel with welded joints and anti-slip surfaces, ensuring sheets remain stable during lifting, transport, and storage. Unlike wood—which splinters, warps, and absorbs moisture—the metal rack delivers consistent performance year after year, even in humid or outdoor-adjacent environments.

A key innovation lies in its forklift-friendly geometry. Integrated fork pockets are precisely positioned to align with standard forklift tines, allowing secure, balanced lifting without additional rigging or slings. This not only speeds up material movement but also reduces the risk of accidental drops. Combined with the single-operator use capability, facilities can cut labor requirements while maintaining—or even improving—throughput.

The rack’s modular design accommodates common sheet sizes used across global industries:

- 2440×1220mm (standard plywood/metal sheet size)

- 3000×1500mm (common in European fabrication)

- 3600×1500mm (used in structural and architectural applications)

Each configuration is tested for optimal load distribution. For example, the 3600mm model supports 3,000 kg per drawer with 15 layers spaced 150mm apart—ideal for thick-gauge steel or stainless sheets. Crucially, all models adhere to the 4,000mm maximum sheet length rule, preventing mid-span sag during forklift handling. This engineering discipline reflects a deep understanding of real-world physics, not just theoretical capacity.

Beyond strength, the system prioritizes workflow intelligence. Sheets are stored horizontally in clearly separated compartments, eliminating contact between layers that could cause scratching or burring—critical for pre-painted or coated metals. Color-coded frames (blue/white, black/red, etc.) further aid visual management, helping workers quickly identify material types or project batches.

Applications span multiple sectors:

- Industrial equipment manufacturers use it to stage raw materials before CNC punching.

- Construction suppliers organize rebar mesh and roofing panels.

- Heavy machinery builders rely on it for storing large base plates prior to welding.

Perhaps most compelling is the rack’s role in safety compliance. By keeping sheets elevated off the floor and contained within rigid boundaries, it eliminates tripping hazards and uncontrolled edge exposure. The dual-side access also means operators don’t need to walk around unstable stacks—reducing ergonomic strain and accident potential.

In an era where OSHA standards and insurance premiums hinge on workplace safety records, investing in a purpose-built Metal Sheet Forklift Rack is both a practical and strategic decision. It transforms chaotic stockrooms into orderly, efficient, and compliant storage zones—proving that smart storage is the unsung hero of industrial excellence.

Factory

Hot Selling Machines

-

Heavy Duty Sheet Metal Storage Racks

Intelligent Production Line CNC Automated Storage Rack: Precision Meets Automation

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drawer-Style Sliding Sheet Metal Storage Rack – Efficient & Safe Material Handling

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Design for Steel Plate Storage with Heavy Duty Drawer Type Sheet Metal Rack Storage System

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Rack for Heavy Plates and Molds: Durable, Efficient Storage for Industrial Applications

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drive-In Pallet Rack Alternative: Space-Saving Drawer-Type Sheet Metal Storage with Automated Retrieval Compatibility

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Drawer Type Plate Shelves Warehouse Rack System for Industrial Metal Storage – 3-Ton Capacity per Layer

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Warehouse Storage System: Customizable Solutions for Metal Plate & Industrial Storage

Read moreRated 0 out of 5 -

Automated Storage Systems

Smart Fixed Profile Stereo Warehouse: Cost-Effective Automation for Small to Mid-Sized Fabrication Shops

Read moreRated 0 out of 5

Related products

Related products

-

Heavy Duty Sheet Metal Storage Racks

High-Density Heavy Duty Steel Plate Shelving Rack

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Revolutionize Material Handling with Forklift-Compatible Sheet Metal Racks

Read moreRated 0 out of 5