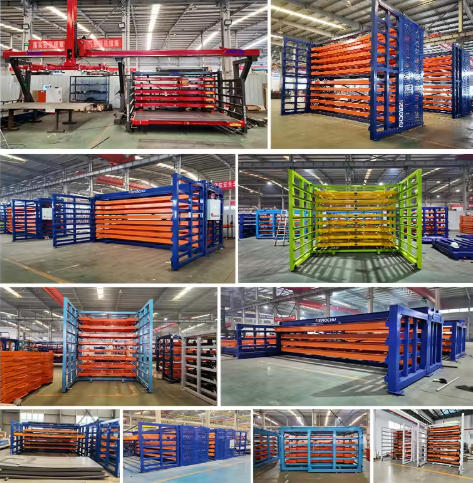

Sheet metal storage systems provide comprehensive solutions for organizing and efficiently storing sheet metal materials in industrial settings. These systems are designed to enhance accessibility, improve inventory management, and maximize space utilization, offering a reliable and efficient storage option for businesses.

Design Features

- Classified Storage: The systems support classified storage of different pipes and sheet metal types, ensuring clear quantity tracking and easy identification of materials.

- Vertical Space Utilization: By storing materials vertically, these systems optimize available space, increasing storage capacity without requiring additional floor area.

- Efficient Material Handling: The drawer-style design and sleepers on pallets facilitate easy access and precise placement of materials, streamlining handling processes.

Quality Advantages

- High-Quality Materials: Components are made from premium carbon steel, ensuring durability and long service life under heavy usage.

- Robust Construction: CO2 shielding welding is used to reinforce frame joints, enhancing structural integrity and preventing weak points.

- Corrosion Protection: Plastic spraying and blackening treatments provide effective protection against rust and corrosion, extending the lifespan of the equipment.

- Precision Components: Travel wheels and shafts are precision-turned from 45# steel, ensuring smooth operation and reducing maintenance needs.

- Rigorous Testing: Each system undergoes comprehensive load testing before deployment, ensuring safety and reliability under operational conditions.

R&D Advantages

- Advanced Design Tools: Utilizing 3D software and simulation technology, the design process is optimized for efficiency and accuracy, with products undergoing detailed finite element stress analysis.

- Specialized Divisions: The company’s Board and Tube Storage Division and Intelligent Storage Division focus on developing innovative solutions tailored to specific industrial needs.

- Expert Engineering Team: With a team of over 20 professionals, including six engineers, the company ensures continuous innovation and high-quality product development.

Benefits

- Improved Inventory Management: Classified storage and clear quantity tracking enhance inventory control, reducing confusion and improving management efficiency.

- Increased Storage Capacity: Vertical space utilization allows for more materials to be stored in a smaller footprint, optimizing warehouse space.

- Enhanced Operational Efficiency: Easy access and efficient material handling features reduce handling time and labor costs, boosting overall productivity.

- Reliable Performance: The robust construction and rigorous testing ensure safe and reliable operation, minimizing risks in industrial environments.

By implementing these advanced heavy-duty steel racking solutions, businesses can significantly enhance their sheet metal storage capabilities, improve operational efficiency, and achieve better inventory management. These systems offer a blend of durability, customization, and innovation, making them ideal for modern industrial applications.