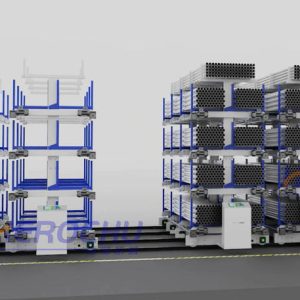

New Type Pipe Storage Cantilever Racking System – High-Load Storage for Steel Tubes & Profiles in Modern Warehouses

The evolution of industrial storage has always been driven by the need to accommodate larger, heavier, and more diverse materials – and steel tubes and profiles are no exception. Modern warehouses require storage solutions that are not only robust and high-load capable but also flexible, efficient, and aligned with the latest engineering standards. Herochu’s New Type Pipe Storage Cantilever Racking System is engineered to meet these demands, offering a cutting-edge storage solution for steel tubes and profiles that combines innovative design, superior performance, and adaptability to modern industrial workflows. As a dedicated manufacturer of storage systems for steel tubes and profiles, we have reimagined cantilever racking to deliver exceptional value to businesses seeking to optimize their storage operations.

Factory

Hot Selling Machines

-

Heavy Duty Sheet Metal Storage Racks

Intelligent Production Line CNC Automated Storage Rack: Precision Meets Automation

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drawer-Style Sliding Sheet Metal Storage Rack – Efficient & Safe Material Handling

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Design for Steel Plate Storage with Heavy Duty Drawer Type Sheet Metal Rack Storage System

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Rack for Heavy Plates and Molds: Durable, Efficient Storage for Industrial Applications

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drive-In Pallet Rack Alternative: Space-Saving Drawer-Type Sheet Metal Storage with Automated Retrieval Compatibility

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Drawer Type Plate Shelves Warehouse Rack System for Industrial Metal Storage – 3-Ton Capacity per Layer

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Warehouse Storage System: Customizable Solutions for Metal Plate & Industrial Storage

Read moreRated 0 out of 5 -

Automated Storage Systems

Smart Fixed Profile Stereo Warehouse: Cost-Effective Automation for Small to Mid-Sized Fabrication Shops

Read moreRated 0 out of 5

Related products

Related products

-

Heavy Duty Cantilever Racking System

Steel Tube Storage Racks & Cantilever Racks

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Rail Type Telescopic Cantilever Shelves for Profile Steel Pipe Storage

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Hand-Operated Telescoping Cantilever Shelving – Flexible, Adaptable Warehouse Storage

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Maximize Storage Efficiency with a Heavy Duty 5+1Layer Steel Cantilever Rack

Read moreRated 0 out of 5