The Ultimate Solution for Organized Metal Storage

In today’s competitive industrial landscape, optimizing warehouse space and improving operational efficiency are critical to maintaining profitability. Heavy Duty roll out sheet metal storage racks represent a revolutionary approach to material handling that addresses these challenges head-on. These innovative storage systems offer a perfect blend of flexibility, durability, and accessibility, making them indispensable for modern fabrication shops and manufacturing facilities.

Modular Design for Changing Needs

One of the standout features of roll out sheet metal storage racks is their inherently flexible and modular design. Unlike traditional static shelving systems, these dynamic storage solutions can adapt seamlessly to evolving business requirements. Whether your operation is experiencing growth, seasonal fluctuations, or product line changes, roll out sheet metal storage systems provide the adaptability needed to keep pace with your business without requiring costly infrastructure upgrades.

The modular nature of these racks allows for easy reconfiguration as storage needs change. Drawers can be added or removed, configurations can be adjusted, and the system can be expanded or reduced in size – all without compromising structural integrity or performance. This future-proof design ensures that your investment in storage infrastructure remains relevant and valuable for years to come.

Safety and Accessibility Improvements

By removing materials from floor space and elevating them onto dedicated storage racks, these systems create a significantly safer work environment. Floor clutter is eliminated, reducing trip hazards and improving overall workplace safety. The ergonomic design of roll out sheet metal storage racks ensures that materials remain accessible while maintaining safe working conditions.

These dynamic systems are engineered to deliver products to pickers in an efficient manner, eliminating the need for strenuous lifting or awkward reaching. Workers can access materials at optimal heights, reducing physical strain and minimizing the risk of workplace injuries. This ergonomic advantage translates into improved productivity and reduced workers’ compensation claims.

Space Optimization Benefits

Heavy Duty sheet metal Warehouse Storage solutions offer an organized, dense, and accessible system for large and heavy items. The vertical orientation of these racks maximizes available floor space, allowing businesses to store more materials in less area. This vertical density is particularly beneficial for facilities operating in high-cost real estate markets or those with limited available space.

Our standard design accommodates up to 12 drawers, providing ample storage capacity while maintaining easy access to individual components. The intelligent layout ensures that frequently used items are within easy reach while less commonly accessed materials are stored in less prime locations – all without sacrificing accessibility when needed.

Customization Options

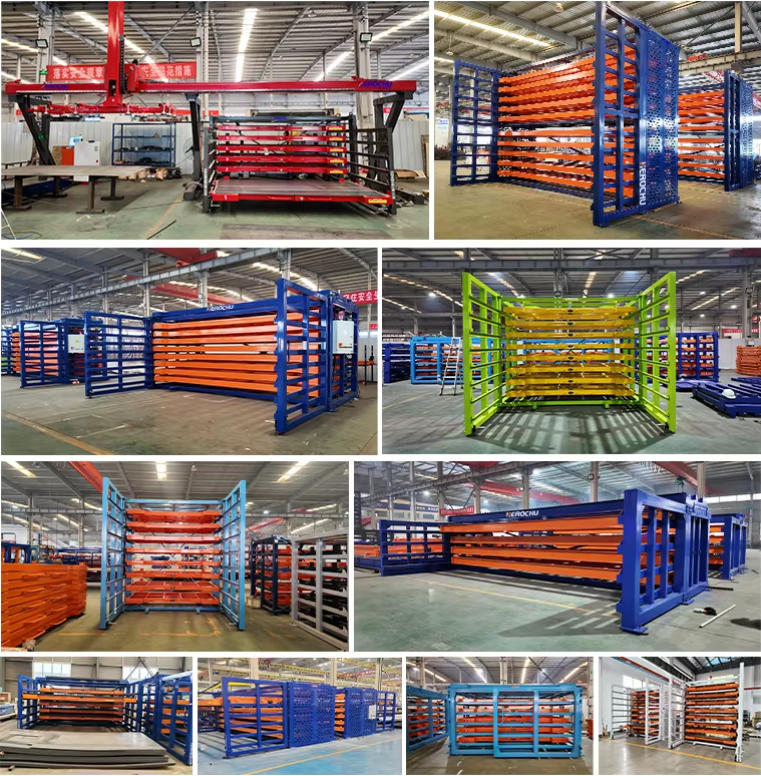

Recognizing that every facility has unique storage requirements, our roll out sheet metal racks are completely customizable. Businesses can choose from a wide variety of configurations to precisely match their material handling needs. Whether you’re storing large steel plates, smaller metal components, or a combination of materials, there’s a configuration that will work perfectly for your operation.

The customization options extend beyond basic layout – businesses can specify drawer sizes, load capacities, and special features based on their specific materials and workflow requirements. Should your needs change over time, these storage systems can be easily modified, ensuring long-term adaptability to your evolving business environment.

Industry Applications

Due to their high level of customization, roll out sheet metal storage racks find applications across diverse industries. These systems are particularly well-suited for aerospace, consumer electronics, industrial manufacturing, defense/military, and automotive sectors. The ability to store flat products, weapons, or parts that are handled with a bridge crane (rather than a lift truck) makes these racks indispensable in specialized manufacturing environments.

Material Compatibility

While designed specifically for metal storage, these versatile systems can accommodate a wide range of materials beyond traditional sheet metal. Alloy steel, aluminum, copper, stainless steel, and even non-metallic materials like polypro, ABS, nylon, acrylic, wood, and glass can be stored efficiently using these innovative storage solutions. This broad material compatibility makes roll out sheet metal storage systems valuable assets in diverse manufacturing settings.

Corrosion Protection and Durability

The Corrosion Protected & Powder Coated Steel Rack System offers long-lasting performance in various industrial environments. The powder-coated finish provides enhanced resistance against rust and corrosion, significantly extending the lifespan of the storage equipment even in harsh conditions.

This protective coating ensures optimal performance for laser cutting metal sheet storage applications, where precision and cleanliness are paramount. The smooth surface allows for easy material handling and prevents contamination of stored metal sheets.

Structural Design Advantages

The Multilayer Structural Design of these storage systems ensures efficient use of vertical space for optimal organization. By stacking storage layers vertically, businesses can maximize their available footprint while maintaining easy access to stored materials.

The Skeletal Structure provides robust stability and durability for heavy loads, ensuring safe operation even under maximum capacity conditions. This structural integrity is maintained across the 2.5-6m layer length options, offering versatile configuration possibilities for different warehouse layouts and material dimensions.

Forklift Compatibility

These storage systems are designed for Easy Forklift Loading, incorporating features that facilitate smooth material handling. The open design and strategic placement of support beams allow for easy access by forklift operators, significantly improving material transfer efficiency between storage and production areas.

About the Manufacturer

Jinan Hengchu Storage Machinery Manufacturing Co., Ltd. is a professional manufacturer of storage equipment that integrates R&D, production, sales, installation, and service. With over 15 years of industry experience, we’ve established ourselves as experts in heavy-duty storage solutions.

Our comprehensive product lineup includes laser-cut metal shelves, drawer-type metal shelves, telescopic cantilever metal shelves, heavy-duty metal and pipe material shelves, and automatic loading and unloading metal material warehouses. These products are designed to work seamlessly with laser cutting machines, shearing machines, cutting machines, and other metal processing equipment.

Industry Applications

Our storage solutions are widely applied across numerous industries including electronics and electrical appliances, mechanical manufacturing, medicine and health, logistics and distribution, automobiles, food, railways, petrochemicals, and textiles. The versatility and reliability of our products have earned them widespread favor among users in these diverse sectors.

Comprehensive Services

We offer exclusive one-on-one service to ensure each customer receives personalized attention and tailored solutions. Our services include free design drawings to help visualize the optimal storage configuration for your facility, on-site installation by trained professionals, and access to a dedicated professional after-sales team for ongoing support and maintenance.

Frequently Asked Questions

Can I request a custom size or color? Absolutely. We offer complimentary design services and deliver efficient, tailored solutions to meet your specific requirements. Our customization options ensure you get exactly what you need for your unique storage challenges.

Are you a manufacturer or distributor? We are a direct manufacturer with extensive experience in designing and producing high-quality storage solutions. This direct relationship allows us to maintain strict quality control and offer competitive pricing.

Is there a minimum order quantity? No. We welcome orders of any size, starting from a single unit. Whether you’re outfitting a small fabrication shop or a large industrial facility, we can accommodate your needs.

How do I provide my storage rack requirements? Simply share the type, dimensions, and quantity of materials you plan to store, along with any other specific needs. Our team will develop a professional storage solution tailored to your operation. Alternatively, you can leave your contact details for a personalized consultation with our experts.