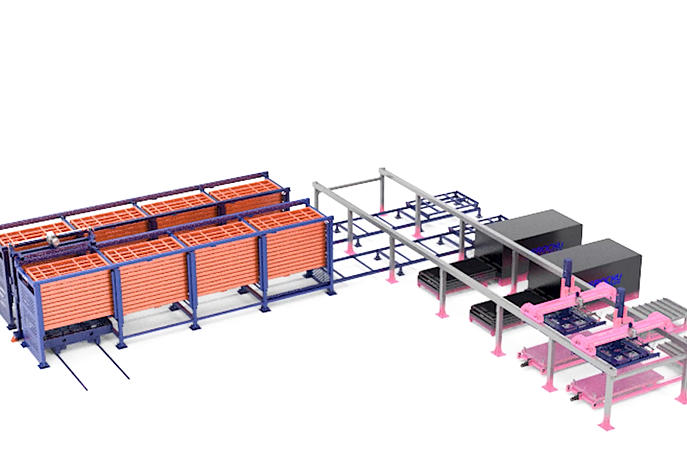

Twin-Tower, Four-Aisle Metal Plate Storage and Side-Discharge Rack System with Dual-Beam Manipulator

The trend towards unmanned factories is transforming the metal processing industry, with automation becoming the cornerstone of efficient and competitive operations. A key enabler of this transformation is the Twin-Tower, Four-Aisle Metal Plate Storage and Side-Discharge Rack System with Dual-Beam Manipulator—a fully integrated storage solution that combines advanced automation technology with a space-saving design to support seamless, unmanned production workflows. This system is specifically engineered to address the unique challenges of metal plate storage and handling, providing factories with a reliable, efficient, and cost-effective solution.

The trend towards unmanned factories is transforming the metal processing industry, with automation becoming the cornerstone of efficient and competitive operations. A key enabler of this transformation is the Twin-Tower, Four-Aisle Metal Plate Storage and Side-Discharge Rack System with Dual-Beam Manipulator—a fully integrated storage solution that combines advanced automation technology with a space-saving design to support seamless, unmanned production workflows. This system is specifically engineered to address the unique challenges of metal plate storage and handling, providing factories with a reliable, efficient, and cost-effective solution.

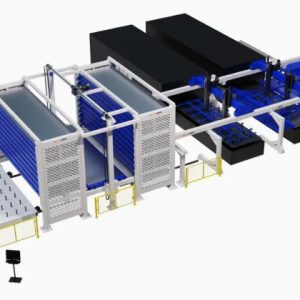

The Twin-Tower, Four-Aisle configuration is a defining feature of this rack system, offering exceptional storage capacity and accessibility. The two towers are connected by four aisles, which allow the dual-beam manipulator to move freely between storage positions, ensuring fast and efficient retrieval of materials. This configuration maximizes the use of vertical and horizontal space, enabling factories to store large volumes of metal plates without compromising on accessibility. Unlike traditional storage systems that require manual navigation between rows, this automated system ensures that every storage position is easily reachable, reducing retrieval time and improving productivity.

The side-discharge functionality of the rack system is critical for integrating with unmanned production lines. By unloading materials to the side of the rack, the system can directly feed metal plates into downstream equipment such as laser cutting machines, automatic stamping centers, robotic bending machines, and welding lines. This eliminates the need for intermediate material handling steps, reducing the risk of damage and delays. The side-discharge feature also allows for parallel operations, with the manipulator retrieving materials while the production line processes them, further improving efficiency.

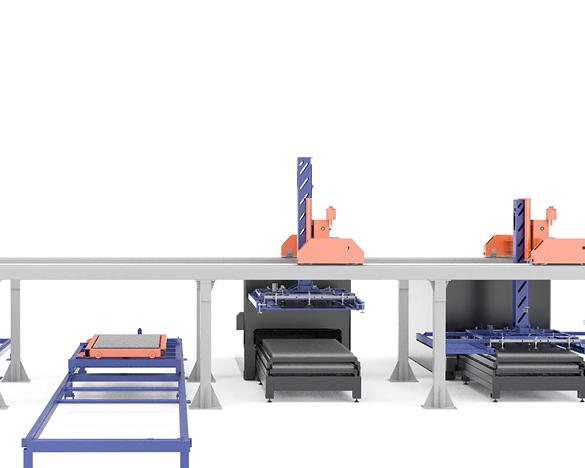

The dual-beam manipulator is the workhorse of this system, designed to handle the heavy loads and precise movements required for metal plate handling. The dual-beam design provides superior stability and lifting capacity, making it suitable for handling plates of varying sizes and weights. The manipulator is equipped with advanced grippers and sensors that ensure secure and accurate handling, reducing the risk of material slippage or damage. Controlled by a sophisticated computer system, the manipulator operates with consistent precision, eliminating the variability associated with manual handling.

The fully automated operation of the Twin-Tower, Four-Aisle Metal Plate Storage and Side-Discharge Rack System with Dual-Beam Manipulator is what truly empowers unmanned factories. The system is integrated with a central computer control system that manages all aspects of storage, retrieval, and material flow. When materials arrive, they are placed on the loading positioning table, where the system automatically identifies and aligns them. The dual-beam manipulator then transports the plates to the appropriate storage position in the twin towers, and the computer records all relevant data in a digital inventory system. This eliminates the need for manual inventory management, reducing errors and improving traceability.

When production requires specific materials, the computer system uses the inventory data to locate the plates and instruct the manipulator to retrieve them. The manipulator then unloads the plates to the side of the rack, where they are transported directly to the production line. This fully automated process ensures that materials are delivered to the production line exactly when needed, minimizing downtime and maximizing productivity. The system also supports batch processing and quick changeovers, allowing factories to switch between different product types with ease.

Space saving is a significant advantage of this rack system. By utilizing vertical space and optimizing the layout with four aisles, the system can store more materials in a smaller footprint compared to traditional storage methods. This is particularly important for factories that are looking to expand their production capacity without investing in additional floor space. The compact design also makes it easier to integrate the system with existing production equipment, reducing the cost and time of installation.

Integration with MES and other factory automation systems further enhances the capabilities of this rack system. The MES system provides real-time data on production schedules, equipment status, and inventory levels, allowing the rack system to adjust its operations dynamically. For example, if a production line requires an urgent delivery of materials, the system can prioritize the retrieval of those plates, ensuring that production is not delayed. This integration also enables predictive maintenance, with the system monitoring the performance of the dual-beam manipulator and other components to identify potential issues before they cause downtime.

Safety is a top priority in the design of this system. The automated operation minimizes human interaction with heavy metal plates, reducing the risk of workplace accidents. The system features multiple safety mechanisms, including overload protection, emergency stop buttons, safety barriers, and real-time monitoring. The four-aisle design also ensures that the manipulator has clear paths of movement, reducing the risk of collisions. Additionally, the system’s computer control system can detect and respond to potential safety hazards quickly, ensuring that operations are always safe.

The Twin-Tower, Four-Aisle Metal Plate Storage and Side-Discharge Rack System with Dual-Beam Manipulator is suitable for a wide range of metal processing applications, including automotive, aerospace, construction, and electronics manufacturing. It can handle various types of metal plates, including stainless steel, aluminum, copper, and carbon steel, making it a versatile solution for different industries. The system’s modular design allows for customization, so it can be tailored to meet the specific needs of each factory, whether it’s a small workshop or a large-scale unmanned facility.

In conclusion, the Twin-Tower, Four-Aisle Metal Plate Storage and Side-Discharge Rack System with Dual-Beam Manipulator is a critical component for factories looking to embrace the future of unmanned metal processing. Its advanced automation, space-saving design, side-discharge functionality, and integration with factory systems make it a powerful tool for improving efficiency, reducing costs, and enhancing safety. By investing in this system, factories can position themselves at the forefront of the industry, ready to meet the demands of the modern manufacturing landscape.

Factory

Hot Selling Machines

-

Heavy Duty Sheet Metal Storage Racks

Intelligent Production Line CNC Automated Storage Rack: Precision Meets Automation

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drawer-Style Sliding Sheet Metal Storage Rack – Efficient & Safe Material Handling

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Design for Steel Plate Storage with Heavy Duty Drawer Type Sheet Metal Rack Storage System

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Rack for Heavy Plates and Molds: Durable, Efficient Storage for Industrial Applications

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drive-In Pallet Rack Alternative: Space-Saving Drawer-Type Sheet Metal Storage with Automated Retrieval Compatibility

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Drawer Type Plate Shelves Warehouse Rack System for Industrial Metal Storage – 3-Ton Capacity per Layer

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Warehouse Storage System: Customizable Solutions for Metal Plate & Industrial Storage

Read moreRated 0 out of 5 -

Automated Storage Systems

Smart Fixed Profile Stereo Warehouse: Cost-Effective Automation for Small to Mid-Sized Fabrication Shops

Read moreRated 0 out of 5

Related products

Related products

-

Automation Sheet Metal Material Warehouse

Multi-Tower Automated Storage Systems

Read moreRated 0 out of 5 -

Automation Sheet Metal Material Warehouse

Maximizing Efficiency with Dual-Tower Automated Storage Solutions

Read moreRated 0 out of 5 -

Automation Sheet Metal Material Warehouse

Intelligent Automated Industrial Pipe Storage Warehouse

Read moreRated 0 out of 5 -

Automation Sheet Metal Material Warehouse

Automated Vertical Storage for Bars and Tubes

Read moreRated 0 out of 5