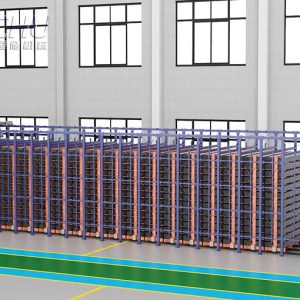

For medium and small-scale sheet metal processing enterprises, the choice of sheet metal storage system needs to balance factors such as efficiency, cost, and space utilization. Traditional manual storage methods are inefficient and cannot meet the needs of growing production, while large-scale intelligent storage systems are often expensive and have high requirements for workshop space, which are not suitable for medium and small-scale enterprises. To fill this gap, Herochu has launched the Automated Storage Rack System for Sheet Metal, a cost-effective and flexible storage solution specifically designed for medium and small-scale sheet metal processing enterprises. This system integrates the advantages of automation, simplicity, and customization, realizing the automatic storage and retrieval of sheet metal with a relatively low cost, helping medium and small-scale enterprises improve storage efficiency and reduce operational costs.

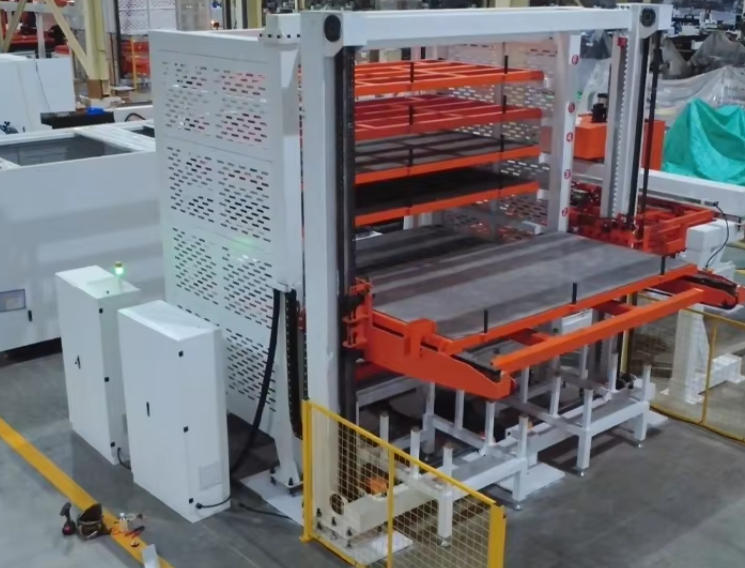

The Automated Storage Rack System for Sheet Metal is designed with simplicity and practicality in mind, while ensuring the automation level and reliability of the system. The system is made of high-quality steel, with a solid drawer-type structure and multi-level racking design, which can effectively utilize vertical space and improve storage capacity. The height of the system ranges from 5 to 15 meters, and the number of layers can be customized according to the customer’s workshop space and storage needs, which can be flexibly adapted to the limited workshop space of medium and small-scale enterprises. The movement mode of the system adopts linear guide rails and chains, which ensures the smooth and stable movement of the storage components. The CNC system uses laser scanning closed-loop positioning technology to achieve precise positioning of sheet metal, ensuring that the storage and retrieval operations are accurate and efficient.

One of the core advantages of the Automated Storage Rack System for Sheet Metal is its cost-effectiveness. Compared with large-scale intelligent three-dimensional storage systems, this system has a more reasonable price, which is more in line with the budget of medium and small-scale enterprises. At the same time, the system adopts a modular design, which is convenient for installation and later expansion. Enterprises can choose the appropriate number of modules according to their current production scale, and add modules when the production scale expands, avoiding the waste of resources caused by one-time large investment. Herochu, as a factory direct sales manufacturer, does not charge design fees and provides customized proposals for free, further reducing the investment cost of enterprises.

The automation function of the system is simple and efficient, which can meet the basic storage needs of medium and small-scale enterprises. The system is equipped with a double-column lifting mechanism for automatic loading and unloading; the motor drives the feeding tray and sheet metal to lift through multiple rows of chains, and the pushing mechanism on the lifting machine hooks one side of the feeding tray to realize the automatic entry and exit of sheet metal. This automatic loading and unloading process eliminates the need for manual handling and forklift operation, reducing labor costs and avoiding the risk of sheet metal damage. The system can be connected to common processing equipment such as laser cutting machines and automatic turret punch presses, realizing automatic material supply, which helps improve the efficiency of the processing equipment and reduce the waiting time for materials.

In terms of inventory management, the Automated Storage Rack System for Sheet Metal provides a simple and practical intelligent solution. The system can be connected to the enterprise’s basic ERP system to realize real-time monitoring of inventory. Every time sheet metal is stored or retrieved, the system automatically records the relevant information, and the inventory data is updated in real time. Enterprise managers can check the inventory status of sheet metal through the control interface, including the quantity, type, and location of materials. This function helps enterprises grasp the inventory dynamics in a timely manner, avoid material shortages or overstocks, and optimize inventory management. Although the inventory management function is not as complex as that of large-scale scheduling centers, it fully meets the basic inventory management needs of medium and small-scale enterprises.

The system also has strong flexibility and customization capabilities. It supports both open and closed storage modes; the closed mode can protect sheet metal from dust and moisture, while the open mode is convenient for daily access. The per-layer loading capacity is 3t/5t, which can meet the storage needs of most sheet metal materials used by medium and small-scale enterprises. The color of the rack can be chosen from orange, blue, or customized colors, which can be matched with the enterprise’s workshop environment. The specification of the system can be customized according to the customer’s workshop layout and storage needs. Herochu’s professional technical team will design the most suitable solution according to the actual situation of the customer, ensuring that the system can be perfectly integrated into the enterprise’s production process.

The application scenarios of the Automated Storage Rack System for Sheet Metal are mainly medium and small-scale sheet metal processing enterprises, such as small and medium-sized hardware factories, electrical equipment workshops, sheet metal processing workshops, and other enterprises with small to medium volume sheet metal storage needs. For example, in a small hardware processing factory, the system can store various types of steel sheets and copper sheets, realizing classified storage and automatic retrieval, which improves the efficiency of material access and reduces the labor intensity of workers. In an electrical equipment workshop, the system can store sheet metal shells of different specifications, providing a reliable material guarantee for the production of electrical products. The system’s simple operation, low maintenance cost, and high reliability make it an ideal choice for medium and small-scale enterprises.

Choosing Herochu’s Automated Storage Rack System for Sheet Metal is a wise choice for medium and small-scale enterprises to improve storage efficiency and reduce costs. Herochu is a professional manufacturer of automatic metal storage systems with rich experience in producing and selling storage equipment for medium and small-scale enterprises. The company has a complete after-sales service system, providing installation guidance, commissioning, and maintenance services to ensure that customers can use the system smoothly. The factory direct sales price and free design proposal enable enterprises to obtain high-quality automatic storage solutions at a lower cost. In addition, Herochu’s products adopt standard export packaging, which can meet the needs of enterprises with export-oriented production. With the support of this system, medium and small-scale enterprises can gradually realize the automation of sheet metal storage, improve production efficiency, and enhance their competitiveness in the market.