Innovative Material Handling Solutions: The Servo Swing Arm Manipulator for CNC Operations

Material handling is a critical aspect of industrial production, and the Servo Swing Arm Manipulator stands out as a innovative solution for CNC machine environments. This article explores the features, benefits, and technical aspects of this advanced robotic arm, designed to streamline loading and unloading processes.

Material handling is a critical aspect of industrial production, and the Servo Swing Arm Manipulator stands out as a innovative solution for CNC machine environments. This article explores the features, benefits, and technical aspects of this advanced robotic arm, designed to streamline loading and unloading processes.

Introduction to the Servo Swing Arm Manipulator

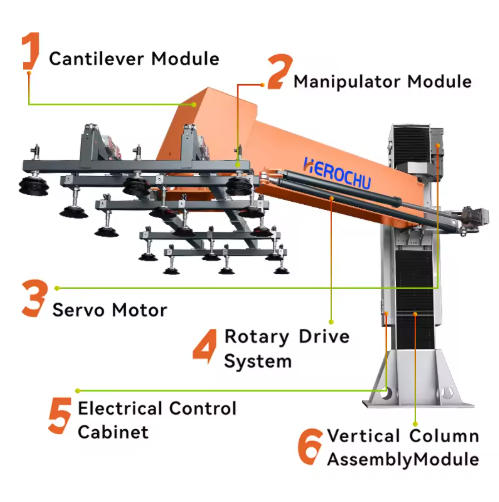

The Servo Swing Arm Handling Manipulator is a cutting-edge device engineered to enhance material handling efficiency. Its servo-driven technology ensures precise control over movements, making it ideal for intricate CNC operations. The swing arm design allows for a wide range of motion, enabling seamless interaction with various workpieces.

Core Features and Advantages

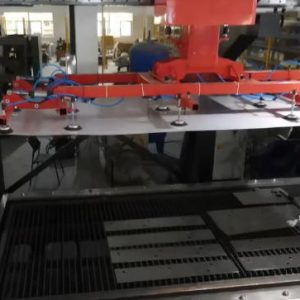

- Automated Loading and Unloading Manipulator for CNC Machine: This robot excels in feeding raw materials into CNC machines and retrieving finished products, reducing manual intervention and improving accuracy.

- Material Handling, Loading and Unloading: Optimized for smooth material flow, the manipulator minimizes delays and ensures consistent production rates.

- Servo Driven Swing Arm Robot Arm for Handling Industrial Automation: The servo motor provides exceptional control, allowing for delicate handling of materials without sacrificing speed.

- Advanced Compound Servo Swing Arm Robot for Loading and Unloading: Incorporating multiple servo systems enhances performance, offering greater flexibility in handling diverse materials and shapes.

Detailed Technical Specifications

- Maximum Load: 100KG-500KG, catering to a broad spectrum of industrial needs.

- Skip Load: 3T, ensuring robustness for heavy-duty applications.

- Air Consumption: 1.5m³/min, optimized for energy efficiency.

- Air Source: 0.6-0.7Mpa, compatible with standard industrial air systems.

Model HC-RM3015 In-Depth Analysis

- Payload Capacity: 200 kg, ideal for medium-scale operations.

- Reach: 2000 mm, providing extensive coverage within the work area.

- Feeding Plate Thickness: 1-20mm, accommodating various material thicknesses.

- Maximum Plate Weight: 1000kg, suitable for handling large and heavy sheets.

- Maximum Feeding Format: 3000*1500mm, ensuring compatibility with standard sheet sizes.

- Minimum Feeding Format: 1250*1250mm, offering flexibility for smaller components.

- Transport Package: Container, facilitating easy and secure shipping.

- Specification: Customizable, allowing tailored solutions for specific industrial needs.

- Trademark: Herochu, a brand synonymous with quality and innovation.

- Origin: China, reflecting the country’s advanced manufacturing capabilities.

- Production Capacity: 10000set/Year, demonstrating scalability and reliability.

System Integration Overview

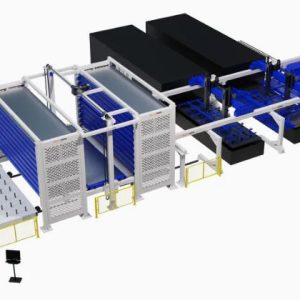

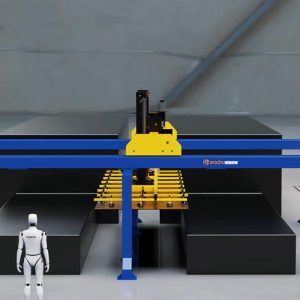

The Servo Swing Arm Manipulator is a key component of an automated sheet metal production unit. This integrated system includes:

- A laser cutting machine with a composite truss manipulator for loading and unloading.

- A double-layer electric exchange material car, enhancing material transport efficiency.

- A CNC control system, ensuring precise operation and easy integration with existing setups.

- A vacuum control system, providing secure grip during material handling.

Together, these elements form a cohesive unit that significantly boosts production efficiency while reducing operational costs.

Why Opt for this Manipulator?

- Enhanced Production Efficiency: By automating loading and unloading, the robot minimizes downtime and maximizes output.

- Cost Reduction: Reduced reliance on manual labor lowers operational expenses and decreases the risk of workplace injuries.

- Versatility: Capable of handling various materials and formats, making it suitable for diverse industrial applications.

- Customization Options: The ability to tailor specifications ensures that the robot meets specific operational requirements.

Company Background

The manufacturer operates a 16000-square-meter modern standard factory building and employs over 100 dedicated professionals. This infrastructure supports a professional service team that offers comprehensive customized services, including production, delivery, and installation guidance. The company’s commitment to quality is evident through its ISO9001 and EU CE certifications, along with strategic partnerships with renowned domestic enterprises. Additionally, it holds several technical patents and has been recognized with prestigious titles such as “AAA Credit Enterprise” and “Honest Entrepreneur”.

Packaging and Delivery Details

- Package Size: 320.00cm * 155.00cm * 155.00cm, designed for efficient storage and transport.

- Package Gross Weight: 1300.000kg, ensuring robust protection during shipping.

Conclusion

The Servo Swing Arm Manipulator is a transformative solution for material handling in CNC operations. Its advanced servo technology and swing arm design offer unmatched efficiency, precision, and versatility. By integrating this robot into your production line, you can achieve significant improvements in productivity and cost savings, positioning your business for long-term success in the competitive industrial landscape.

Factory

Hot Selling Machines

-

Heavy Duty Sheet Metal Storage Racks

Intelligent Production Line CNC Automated Storage Rack: Precision Meets Automation

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drawer-Style Sliding Sheet Metal Storage Rack – Efficient & Safe Material Handling

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Design for Steel Plate Storage with Heavy Duty Drawer Type Sheet Metal Rack Storage System

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Rack for Heavy Plates and Molds: Durable, Efficient Storage for Industrial Applications

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drive-In Pallet Rack Alternative: Space-Saving Drawer-Type Sheet Metal Storage with Automated Retrieval Compatibility

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Drawer Type Plate Shelves Warehouse Rack System for Industrial Metal Storage – 3-Ton Capacity per Layer

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Warehouse Storage System: Customizable Solutions for Metal Plate & Industrial Storage

Read moreRated 0 out of 5 -

Automated Storage Systems

Smart Fixed Profile Stereo Warehouse: Cost-Effective Automation for Small to Mid-Sized Fabrication Shops

Read moreRated 0 out of 5

Related products

Related products

-

Sheet Metal Handling Equipment

Gantry Loading System for Fiber Laser and Cutting Lines

Read moreRated 0 out of 5 -

Sheet Metal Handling Equipment

Automatic Storage System Steel Metal Plate Gantry Loading Unloading Robot Manipulator

Read moreRated 0 out of 5 -

Sheet Metal Handling Equipment

Steel Plate Material Handling Equipment for Modern Manufacturing

Read moreRated 0 out of 5