Small to mid-sized fabrication shops face unique challenges when it comes to material storage and management. Unlike large industrial plants with unlimited resources, these shops often operate with limited floor space, tight budgets, and a small team of employees. They need storage solutions that are efficient, affordable, and easy to use—solutions that can help them improve productivity, reduce costs, and compete with larger facilities. The Smart Fixed Profile Stereo Warehouse is specifically designed to meet these needs. This cost-effective automation solution combines high-density storage, simple operation, and flexible design to provide small to mid-sized fabrication shops with the same level of efficiency and control as larger facilities, without the high cost and complexity of traditional industrial automation systems.

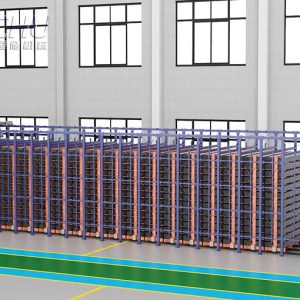

For small to mid-sized fabrication shops, every square foot of floor space is valuable. Many of these shops operate in small facilities where floor space is at a premium, making it difficult to store large volumes of long-length materials such as bars, tubes, and pipes without cluttering the production area. Traditional ground-level racking takes up valuable floor space, leaving little room for production equipment, workstations, and finished goods. The Smart Fixed Profile Stereo Warehouse solves this problem by leveraging vertical space, creating a three-dimensional storage matrix that stores more materials in less area. A typical single-tower system stands between 30 to 52 feet tall and occupies less than 300 square feet of floor space—enough to store hundreds of SKUs of material without taking over the production area. This space savings allows small to mid-sized shops to reclaim valuable floor space for additional production equipment or workstations, helping them increase productivity and grow their business.

Cost is another critical factor for small to mid-sized fabrication shops. Many automation solutions are prohibitively expensive, requiring large upfront investments that are beyond the budget of most small businesses. The Smart Fixed Profile Stereo Warehouse is designed to be cost-effective, with a competitive price point that makes it accessible to small to mid-sized shops. Unlike traditional automation systems that require complex installation and expensive maintenance, this system is easy to install and maintain, reducing long-term costs. Additionally, the system’s automation capabilities reduce labor costs by eliminating the need for manual material handling, allowing shops to do more with fewer employees. This is particularly valuable for small shops that struggle with labor shortages and high labor costs.

The Smart Fixed Profile Stereo Warehouse is also designed to be easy to use, with a user-friendly HMI that requires minimal training. Many small to mid-sized shops do not have the resources to hire specialized technicians to operate complex automation systems, so the system’s intuitive controls allow any employee to operate it with minimal training. The HMI provides clear, concise instructions for storing and retrieving materials, and it allows operators to view inventory levels, generate reports, and initiate tasks with just a few clicks. This ease of use ensures that the system can be integrated into the shop’s workflow quickly and seamlessly, without disrupting production.

Despite its simplicity, the Smart Fixed Profile Stereo Warehouse offers powerful features that rival those of more expensive industrial automation systems. The system’s automated retrieval mechanism ensures that materials are retrieved quickly and accurately, reducing retrieval time from minutes to seconds. This eliminates the need for operators to spend hours searching for materials, allowing them to focus on more value-added tasks such as production and quality control. The system’s real-time inventory tracking ensures that shop owners always know exactly what materials are on hand, preventing stockouts and overordering. This helps shops reduce inventory holding costs and minimize material waste, improving their bottom line.

Flexibility is another key benefit of the Smart Fixed Profile Stereo Warehouse for small to mid-sized fabrication shops. These shops often handle a wide range of material types and sizes, from small diameter pipes to large structural sections, and they need a storage solution that can accommodate this variety. The system’s modular design allows it to be customized to meet the unique needs of any shop, with drawers available in a wide range of sizes and weight capacities. Drawer lengths range from 10 feet to 40 feet, widths from 1.3 feet to 6.5 feet, and weight capacities between 3,300 and 11,000 pounds per drawer. This flexibility allows the system to accommodate a wide range of materials, making it suitable for shops that handle everything from custom fabrication to high-volume production.

The system can also be configured as a single tower or a double tower, depending on the shop’s storage needs and available space. Single-tower systems are ideal for small shops with limited space, while double-tower systems offer higher storage density for mid-sized shops that need to store more materials. The system can also be expanded easily as the shop grows, with additional drawers or towers added to meet increasing storage demands. This scalability ensures that the system can grow with the shop, providing long-term value and eliminating the need to replace the system as the business expands.

For small to mid-sized fabrication shops that work with multiple customers, the Smart Fixed Profile Stereo Warehouse’s inventory management features are particularly valuable. The system allows shops to track materials by customer, order, or project, ensuring that materials are reserved for specific jobs and preventing mix-ups. This is critical for shops that handle custom orders, as it ensures that the right materials are used for each job, reducing rework and improving customer satisfaction. The system can also generate detailed inventory reports, allowing shop owners to analyze material usage, identify trends, and make informed decisions about purchasing and inventory management.

Safety is another important consideration for small to mid-sized fabrication shops, which often have limited resources to invest in safety equipment and training. The Smart Fixed Profile Stereo Warehouse is designed with multiple safety features to protect operators and equipment, including emergency stop buttons, safety gates, and motion sensors. The system’s automated retrieval mechanism eliminates the need for operators to climb ladders, lift heavy materials, or work in dangerous areas, reducing the risk of workplace injuries. This not only protects employees but also reduces the risk of costly workers’ compensation claims and downtime.

The system’s design also protects materials from damage, which is critical for small shops that cannot afford to waste expensive materials. The drawers are designed to hold materials securely, preventing movement and damage during storage and retrieval. Open-bottom drawers allow swarf, coolant, and debris to fall through, keeping materials clean and free from contaminants. Closed-side drawers are available for round stock, preventing roll-off and ensuring that materials remain secure. All components of the system are constructed from high-quality steel that is resistant to corrosion and wear, ensuring long-term reliability even in harsh shop environments.

Seamless integration with existing shop equipment is essential for small to mid-sized fabrication shops, which often have limited resources to invest in new equipment. The Smart Fixed Profile Stereo Warehouse is designed to integrate with a wide range of shop equipment, including CNC saws, laser cutters, and machining centers. The system can connect to these machines via Ethernet/IP, Profinet, or Modbus, allowing them to signal the system when materials are needed. This integration ensures that materials are delivered to the machines exactly when needed, reducing downtime and improving productivity. The system can also integrate with basic inventory management software, eliminating manual data entry and reducing errors.

To understand the real-world impact of the Smart Fixed Profile Stereo Warehouse for small to mid-sized fabrication shops, let’s look at a case study from a small custom fabrication shop. The shop had 5 employees and operated in a 5,000-square-foot facility, storing over 100 SKUs of steel and aluminum bars, pipes, and tubes across 8 ground-level racks. The shop’s operators were spending 15–20 minutes per shift searching for materials, and mispicks were common, leading to costly rework and delays. The shop also struggled with limited floor space, making it difficult to add new production equipment. After installing a single-tower Smart Fixed Profile Stereo Warehouse, the shop saw dramatic improvements: retrieval time dropped to under 90 seconds, mispicks were eliminated, and the floor space previously occupied by racking was reclaimed for a new CNC router. This led to a 25% increase in productivity, a 15% reduction in material waste, and a 20% improvement in on-time delivery rates. The shop was also able to take on more custom orders, increasing revenue by 30%.

Another case study comes from a mid-sized fabrication shop that specializes in structural steel fabrication. The shop had 15 employees and operated in a 10,000-square-foot facility, storing over 200 SKUs of structural steel sections across 15 ground-level racks. The shop was struggling with labor costs and inefficiency, with operators spending hours moving materials with forklifts and manually updating inventory records. After installing a double-tower Smart Fixed Profile Stereo Warehouse, the shop reduced labor costs by 25%, eliminated forklift usage for material retrieval, and improved inventory accuracy to 100%. The shop also freed up floor space for a new welding station, increasing production capacity by 20%.

The Smart Fixed Profile Stereo Warehouse also offers long-term value for small to mid-sized fabrication shops. Its durable construction ensures that it will last for years, providing a long-term return on investment. Its modular design allows for easy expansion, so the system can grow with the shop as it expands. Its low maintenance requirements reduce long-term costs, and its energy-efficient design reduces utility costs. Additionally, the system’s automation capabilities help shops stay competitive by improving productivity and reducing costs, allowing them to compete with larger facilities.

At [Manufacturer Name], we understand the unique challenges facing small to mid-sized fabrication shops, and we are committed to providing cost-effective, easy-to-use storage solutions that help them succeed. As a direct manufacturer with over 15 years of experience, we have the expertise to design and build custom Smart Fixed Profile Stereo Warehouse systems that meet the specific needs of your shop. Our team of engineers will work with you to assess your storage requirements, design a tailored solution, and provide on-site installation and debugging to ensure that your system operates smoothly from day one.

We offer complimentary design services and detailed product information to help you make an informed decision. Whether you need a single-tower system for a small shop or a double-tower system for a mid-sized shop, we have the capabilities to deliver. There is no minimum order quantity, and we offer competitive pricing and flexible payment options to make the system accessible to small businesses. To get a quote or learn more about the Smart Fixed Profile Stereo Warehouse, click the “Get a Quote” button on our website or contact our sales team today.

Our manufacturing facility is located in Jiyang Industrial Park, Jinan, Shandong, China, where we use advanced production equipment and strict quality control processes to ensure that every system we produce meets the highest standards. Our quality assurance program includes ISO9001 certification, CE certification for all exports, rigorous load testing, and a team of 40+ technical engineers who provide professional support. We are proud to serve small to mid-sized fabrication shops around the world, including in the USA, South Korea, Russia, Qatar, Mexico, South Africa, Egypt, and Lebanon, and we are committed to delivering products that exceed their expectations.

In summary, the Smart Fixed Profile Stereo Warehouse is the perfect storage solution for small to mid-sized fabrication shops looking to improve efficiency, reduce costs, and grow their business. Its space-saving design, cost-effective automation, easy-to-use controls, and flexible configuration make it accessible and valuable for shops of all sizes. By investing in this system, you can reclaim floor space, reduce labor costs, eliminate mispicks, and improve inventory management, providing you with the competitive edge you need to succeed in today’s market. Don’t let limited resources hold your shop back—choose the Smart Fixed Profile Stereo Warehouse and take your material management to the next level.