Heavy-Duty Drawer Type Plate Shelves Warehouse Rack System for Industrial Metal Storage – 3-Ton Capacity per Layer

The modern manufacturing and warehousing landscape demands storage solutions that maximize efficiency while maintaining absolute safety standards. Our heavy-duty drawer type plate shelves warehouse rack system represents a significant advancement in industrial storage technology, specifically engineered for facilities handling large quantities of sheet metal, steel plates, and heavy-duty materials. This innovative Drawer-type sheet rack combines robust construction with intelligent design, offering unprecedented access to stored materials while optimizing valuable floor space.

The modern manufacturing and warehousing landscape demands storage solutions that maximize efficiency while maintaining absolute safety standards. Our heavy-duty drawer type plate shelves warehouse rack system represents a significant advancement in industrial storage technology, specifically engineered for facilities handling large quantities of sheet metal, steel plates, and heavy-duty materials. This innovative Drawer-type sheet rack combines robust construction with intelligent design, offering unprecedented access to stored materials while optimizing valuable floor space.

At the core of this system’s exceptional performance lies its remarkable load-bearing capacity. Each layer of this Warehouse Rack supports up to 3 tons of weight, with customized configurations available to handle loads ranging from 3 to 20 tons per tier. This Heavy-duty drawer-type panel storage rack transforms how businesses approach material organization, eliminating the dangerous and time-consuming practice of stacking plates directly on warehouse floors. The multilayer design typically features 5 to 8 layers of storage, effectively multiplying your usable storage area without requiring facility expansion.

The engineering excellence begins with material selection. The main structural components utilize Q235B high-quality carbon steel, a material specifically chosen for its superior strength-to-weight ratio and excellent performance in corrosive industrial environments. This grade of steel provides the foundational durability needed for continuous heavy-duty operations while resisting the degradation common in manufacturing settings exposed to moisture, chemicals, and temperature fluctuations. Unlike standard storage systems that may warp or fail under sustained heavy loads, this drawer-type architecture maintains structural integrity year after year.

Manufacturing precision ensures every joint and connection point exceeds industry standards. The frame employs CO2 shielded welding technology, creating fusion-welded joints that distribute stress evenly across the structure. This welding method produces cleaner, stronger connections than traditional arc welding, eliminating weak points that could compromise safety. Each weld undergoes inspection by certified quality control technicians, ensuring compliance with ISO9001 standards before proceeding to the next production phase. The result is a seamless monolithic structure that behaves as a single unit under load, rather than a collection of connected components.

The revolutionary aspect of this system is its steel slide rail technology, which enables the smooth, full extension of each drawer. Unlike conventional roller-based systems that can bind or require frequent maintenance, these precision-engineered steel rails allow operators to extend drawers completely even when loaded to maximum capacity. This complete extension capability means workers can access materials at the back of the drawer as easily as those at the front, dramatically reducing material handling time and improving workflow efficiency. The sliding mechanism requires minimal force to operate, reducing worker fatigue and the risk of strain injuries during daily operations.

Surface protection represents another critical advantage. The entire structure receives a powder coated finish that significantly enhances rust and corrosion resistance. This electrostatically applied coating creates a uniform barrier that adheres tightly to the steel surface, far superior to conventional paint applications. The powder coating process involves curing at high temperatures, creating a hard, durable finish that resists chipping, scratching, and chemical exposure. For facilities in harsh environments or those handling corrosive materials, this protection layer extends the rack’s functional lifespan by preventing the oxidation that leads to structural weakening.

The versatility of size configurations makes this system adaptable to virtually any facility layout. Standard dimensions include 25001300mm, 30001500mm, 4000x2000mm, and 6000*2000mm platforms, with each layer typically measuring 2.5 to 6 meters in length. This range accommodates everything from small fabrication shops to large-scale manufacturing plants. The cantilever main sub rack form provides exceptional stability, distributing weight through vertical columns while leaving the front of each drawer completely unobstructed for easy loading and unloading with forklifts or overhead cranes.

Application scenarios for this drawer-type architecture span multiple industries. Electronics and electrical appliance manufacturers use these racks to store pressed metal components and enclosures. Machinery manufacturers organize raw steel sheets, cut parts, and work-in-progress materials. The automotive industry relies on these systems for body panel storage and just-in-time delivery organization. Logistics and distribution centers handling metal products benefit from the dense storage capacity and easy retrieval. Even specialized sectors like railway equipment manufacturing, petrochemical processing, and textile machinery production find these racks indispensable for managing heavy, bulky materials.

Integration with existing production workflows represents a key design consideration. These racks work seamlessly alongside laser cutting machines, shearing equipment, and CNC cutting systems. Operators can stage materials adjacent to processing stations, reducing travel distance and handling time. The automated retrieval compatibility means these systems can serve as manual-access storage today while providing the foundation for future automation upgrades. As facilities evolve toward smart manufacturing, the robust construction and precise alignment of these racks support robotic access systems and automated material handling equipment.

Jinan Hengchu Storage Machinery Manufacturing Co., Ltd. brings over 15 years of specialized experience to every rack system produced. As a direct manufacturer with a modern 10,000-square-meter facility located in Jiyang Industrial Park, Jinan, Shandong, China, the company maintains complete control over the production process from raw material inspection to final shipment. This vertical integration ensures consistent quality and allows for rapid customization without the delays common when working through distributors or intermediaries.

The quality assurance process involves multiple validation steps. A dedicated team of over 40 technical engineers oversees professional debugging and installation support, ensuring each system performs as designed. The quality control department operates under strict ISO9001 protocols, with every component traceable through production batch numbers. All export products carry CE certification, demonstrating compliance with European safety and performance standards. Before shipment, each rack undergoes rigorous load testing that verifies structural safety and reliability under real-world conditions. This testing includes static load verification, drawer extension cycle testing, and structural deformation measurement under maximum rated loads.

Installation and ongoing support complete the value proposition. While the system arrives with comprehensive assembly documentation, many customers opt for professional on-site installation services. Experienced technicians travel to facilities worldwide—including locations in the USA, South Korea, Russia, Qatar, Mexico, South Africa, Egypt, and Lebanon—to ensure proper assembly, alignment, and operation. This service includes load testing at installation, operator training, and establishment of maintenance schedules. The professional after-sales team remains available for consultation, troubleshooting, and future expansion planning.

For businesses concerned about customization, the options are extensive. Color customization allows the racks to match corporate branding or facility color-coding systems. Layer height adjustments accommodate specific material dimensions. Capacity modifications can increase per-layer loading to match unusual requirements. The company offers complimentary design services, creating detailed drawings and 3D models that integrate with your facility layout. This design phase considers workflow patterns, equipment placement, safety clearances, and future expansion possibilities, delivering efficient, tailored solutions without design fees.

The absence of wheels on this model ensures maximum stability. Unlike mobile rack systems that can shift under load or during drawer operation, this stationary design anchors securely to the floor, creating a permanent storage infrastructure that becomes part of the facility’s structural organization. This stability proves especially important when using overhead cranes or forklifts to place multi-ton sheets onto the extended drawers. The rack remains absolutely rigid, preventing dangerous movement that could endanger workers or damage materials.

Health and safety benefits extend beyond the obvious stability advantages. By organizing materials in dedicated drawers, facilities eliminate the trip hazards associated with stacked plates and sheets. The controlled extension mechanism prevents sudden drawer movement that could cause crushing injuries. The ergonomic design places materials at optimal heights, reducing bending and lifting injuries. In facilities where employee safety is paramount, these racks demonstrate management’s commitment to providing equipment that protects the workforce while enhancing productivity.

From a financial perspective, the investment returns manifest in multiple ways. The space optimization allows businesses to postpone or eliminate costly facility expansions. Improved material handling efficiency reduces labor hours per job, lowering operational costs. The prevention of material damage—from stacking, moisture exposure, or improper handling—preserves material value and reduces waste. The durability ensures a decade or more of service life, amortizing the initial investment over many years of reliable operation.

The drawer type configuration also supports inventory management and traceability. Each drawer can be designated for specific material grades, thicknesses, or project assignments. Labeling systems integrate with the powder-coated surface, allowing for clear identification. This organization reduces the time spent searching for specific materials and prevents costly errors from using incorrect stock. In quality-controlled environments, this traceability supports audit requirements and material certification tracking.

Environmental considerations factor into both the manufacturing process and long-term operation. The powder coating process emits negligible volatile organic compounds compared to traditional painting. The steel construction is fully recyclable at end-of-life, supporting corporate sustainability initiatives. The extended service life means fewer replacement cycles, reducing the environmental impact associated with manufacturing and transportation of replacement equipment.

For procurement professionals evaluating storage solutions, the supply chain advantages are clear. Direct manufacturing eliminates markup from distributors, providing competitive pricing. The CE and ISO certifications satisfy most corporate and governmental purchasing requirements. The ability to order single units or small quantities allows pilot installations before committing to facility-wide deployment. The transparent pricing structure, provided through detailed quotes that include product images, specifications, and videos, facilitates informed decision-making and budget approval.

The global installation experience means the manufacturer understands diverse operational requirements across different regions. Installations in the USA emphasize OSHA compliance and integration with American-standard handling equipment. European installations focus on CE marking and workspace ergonomics. Middle East projects address extreme temperature conditions and corrosion from environmental factors. This international experience translates into robust design that performs reliably regardless of location or operating conditions.

When considering expansion, the modular nature of these systems simplifies the process. Additional bays connect seamlessly to existing installations, maintaining alignment and load distribution. The consistent design means spare parts remain available years after initial installation, protecting the long-term investment. The manufacturer maintains detailed records of each installation, allowing for precise replication or modification as business needs evolve.

In summary, this heavy-duty drawer type plate shelves warehouse rack system delivers industrial-strength storage that transforms material handling operations. The combination of massive load capacity, precision engineering, corrosion protection, and intelligent design creates a storage infrastructure that supports safety, efficiency, and growth. For any facility handling heavy sheet materials, this system represents not just equipment, but a strategic investment in operational excellence.

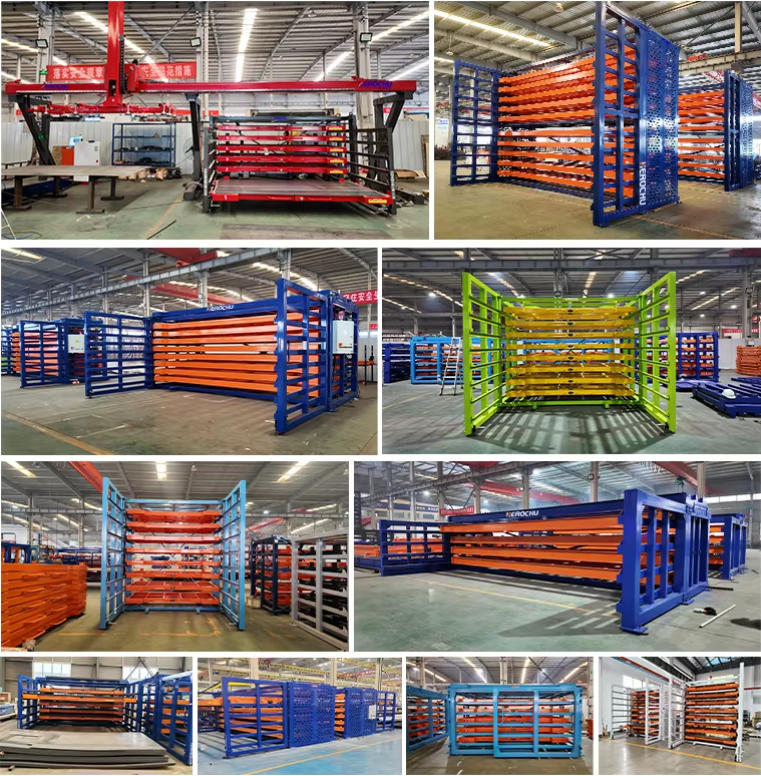

Factory

Hot Selling Machines

-

Heavy Duty Sheet Metal Storage Racks

Intelligent Production Line CNC Automated Storage Rack: Precision Meets Automation

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drawer-Style Sliding Sheet Metal Storage Rack – Efficient & Safe Material Handling

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Design for Steel Plate Storage with Heavy Duty Drawer Type Sheet Metal Rack Storage System

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Rack for Heavy Plates and Molds: Durable, Efficient Storage for Industrial Applications

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drive-In Pallet Rack Alternative: Space-Saving Drawer-Type Sheet Metal Storage with Automated Retrieval Compatibility

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Drawer Type Plate Shelves Warehouse Rack System for Industrial Metal Storage – 3-Ton Capacity per Layer

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Warehouse Storage System: Customizable Solutions for Metal Plate & Industrial Storage

Read moreRated 0 out of 5 -

Automated Storage Systems

Smart Fixed Profile Stereo Warehouse: Cost-Effective Automation for Small to Mid-Sized Fabrication Shops

Read moreRated 0 out of 5

Related products

Related products

-

Heavy Duty Sheet Metal Storage Racks

Industrial Multi-Layer Sheet Metal Storage Rack

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Custom Storage Rack for 6-Meter Plates and Heavy Loads

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy Duty Forklift steel plates Storage Rack

Read moreRated 0 out of 5