For sheet metal processing businesses, every minute of downtime, every case of manual error, and every square meter of wasted workshop space eats into profits. In an industry where speed and precision directly determine market competitiveness, relying on traditional manual loading and unloading for fiber laser cutting machines has become a major bottleneck. The Automatic Loading and Unloading System for Fiber Laser Cutting Machine emerges as a targeted solution to these pain points—it integrates intelligent storage, automated material handling, and precise control into a single ecosystem, turning fragmented, labor-dependent operations into smooth, 24/7 unmanned production lines.

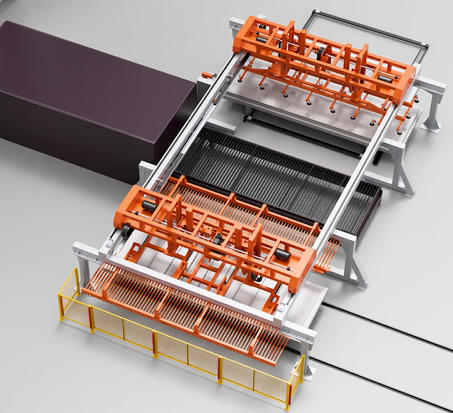

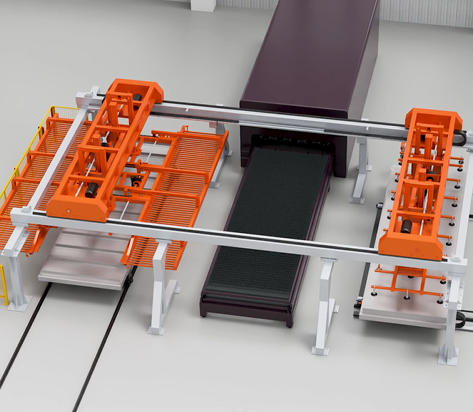

Unlike standalone accessories that only address one part of the workflow, this system is a fully integrated unit built from complementary components, each optimized to work in tandem. At its foundation is a three-dimensional storage warehouse—a space-saving solution that replaces messy, floor-hogging material piles with organized, vertical storage. Supporting this warehouse are a double-sided gantry truss and two specialized manipulators: a loading truss manipulator for moving raw materials and an unloading truss manipulator for handling finished sheets. Rounding out the system are a double-layer finished material truck (for efficient transport of end products), a PLC control system (the “brain” that coordinates all movements), and seamless integration with fiber laser cutting machines—creating a closed-loop production cycle with zero manual handoffs.

One of the most impactful benefits of this system is its ability to unlock the full potential of fiber laser cutting machines, including popular models like Fiber Laser Fly Speed, Fly Pro, Wind, and Mach. These machines are designed for high-speed cutting, but their efficiency is often limited by how quickly materials can be loaded and unloaded. The Automatic Loading and Unloading System eliminates this limitation by ensuring an uninterrupted material flow: its combination loading/unloading device uses soft suction cups to securely grip raw sheets (preventing surface damage) and retractable rakes to gently remove finished parts—no more waiting for operators to manually haul heavy materials.

The speed of this material exchange is a game-changer. With a cycle time of just 65 seconds, the system ensures the laser cutting machine never sits idle between jobs. For a facility running a 10-hour shift, this translates to dozens more cutting cycles compared to manual operations—directly boosting daily output by 20-30% for high-volume orders. Even more valuable is the system’s support for unmanned operation: after programming the production schedule via the PLC control system, businesses can run the line overnight, on weekends, or during holidays without needing to assign staff. This not only cuts labor costs (often one of the largest expenses in sheet metal shops) but also lets businesses meet tight deadlines without overworking their teams.

Storage in sheet metal shops is often an afterthought, leading to cluttered floors, damaged materials, and wasted time searching for the right sheet. The three-dimensional storage warehouse in this system solves this problem head-on. It’s available in multiple specifications to match common sheet sizes: 3015mm, 4015mm, 4020mm, 6015mm, 6020mm, and 6025mm—covering everything from small precision parts to large industrial panels. Businesses can choose between 8-13 storage floors, and each floor supports either 3T or 5T of load, with the entire system handling a maximum load of 300KG to 3000KG. This means even thick steel plates or bulky aluminum sheets can be stored safely and accessed quickly—no more stacking materials on the floor where they’re prone to bending or scratching.

To keep this complex system running smoothly, it relies on two key utility parameters: air consumption and air pressure. The system uses 1.5m³ of compressed air per minute, and requires an air source pressure of 0.6-0.7Mpa. These values are carefully calibrated to ensure the suction cups maintain a strong, consistent grip (even on smooth or slightly textured surfaces) and the manipulators move with stable precision. The PLC control system ties everything together: it lets operators set up production sequences, monitor real-time status (like material levels or machine health), and troubleshoot issues via a user-friendly interface. For example, if a storage floor is low on raw material, the system sends an alert, allowing staff to restock before a shortage causes downtime.

Beyond speed and efficiency, the system also elevates the quality of finished products—a critical factor for businesses serving industries like automotive, aerospace, or medical equipment. Manual handling of sheet metal often leads to avoidable defects: operators might scratch surfaces while moving sheets, misalign materials on the cutting table (causing off-center cuts), or drop small parts (leading to bending). The Automatic Loading and Unloading System eliminates these risks: its suction cups and rakes handle materials with uniform pressure, and the PLC control ensures precise positioning (within ±1mm of accuracy). This results in cleaner cuts, fewer rejected parts, and more consistent output—helping businesses build a reputation for reliability and reducing the cost of reworking or replacing defective products.

Scalability is another key advantage that makes this system a long-term investment. As a business grows—whether by adding more laser cutting machines, expanding product lines, or increasing order volume—the system can grow with it. For instance, if a shop adds a second fiber laser cutter, they can integrate an extra loading/unloading manipulator to the existing gantry truss instead of buying an entirely new system. Similarly, if storage needs increase, additional floors can be added to the three-dimensional warehouse. This flexibility means the system doesn’t become obsolete as operations expand, providing ongoing value for years.

For small to mid-sized shops, the system also addresses the challenge of space optimization. Traditional setups require separate areas for material storage, cutting machines, and finished product staging—often taking up more floor space than necessary. The Automatic Loading and Unloading System consolidates these functions: the three-dimensional warehouse uses vertical space instead of horizontal, and the gantry truss spans over the cutting machines, eliminating the need for extra room for material transport. This frees up valuable floor space for other equipment, like additional cutting tools or assembly stations—helping small shops maximize their operational capacity without moving to a larger facility.

In conclusion, the Automatic Loading and Unloading System for Fiber Laser Cutting Machine is more than just an automation tool—it’s a strategic investment that solves the biggest pain points in sheet metal processing: downtime, labor costs, storage inefficiencies, and quality inconsistencies. By integrating smart storage, fast material handling, and precise control, it turns fiber laser cutting machines into 24/7 profit generators, whether for a small shop handling custom orders or a large manufacturer managing high-volume production. For businesses looking to stay ahead in a competitive market, this system isn’t just an upgrade—it’s a necessity to build efficiency, reduce costs, and deliver consistent quality. Investing in it means investing in a more productive, profitable, and sustainable future for your sheet metal operation.