Material handling inefficiencies plague industries relying on flat stock. Furniture manufacturers waste hours locating specific wood panels. Building material distributors struggle with damaged drywall and warped plywood. Metal fabricators face safety hazards from unstable sheet stacks. Drawer style board shelving fundamentally restructures these operations through layered, independent storage access.

Industry-Specific Storage Challenges

Furniture production demands rapid access to multiple material types—MDF, particle board, plywood, solid wood panels—often in identical dimensions but different specifications. Traditional vertical stacking makes bottom layers inaccessible without moving everything above. This creates a domino effect: workers avoid using optimally sized pieces because retrieval takes too long, instead cutting larger, more accessible sheets and generating excess scrap.

Building material warehouses face similar issues multiplied by volume. A typical distribution center stocks drywall, cement board, insulation panels, and composite sheeting. Stacking these materials causes compression damage to lower layers. Drywall corners crush easily under weight. Cement board develops stress fractures. The result is material waste rates exceeding 8-10% in poorly organized facilities.

Metal processing shops encounter additional hazards. Steel sheets, especially large formats like 6×2 meters, become unstable when stacked more than one meter high. Forklift operators risk tip-overs when retrieving sheets from mid-stack. Workers face pinch-point injuries when manually separating stacked metal. Drawer style board shelving eliminates these hazards by providing individual access points for each material type and size.

Mechanical Operation Principles

Each drawer unit operates on precision rollers or heavy-duty slide rails rated for specific loads. The HC-B3015-63 model’s 3-ton capacity suits medium-density materials like plywood and MDF. The HC-B6020-610’s 10-ton rating handles steel plate storage. This engineering specificity ensures smooth operation under realistic loads—not theoretical maximums that fail in daily use.

The hand crank mechanism provides mechanical advantage through a worm gear reduction system. Operators rotate the crank with minimal force; the gear system translates this into controlled drawer movement. For heavier loads, electric motors drive the mechanism via chain or belt drive systems, maintaining consistent speed regardless of drawer weight.

Customization for Material Characteristics

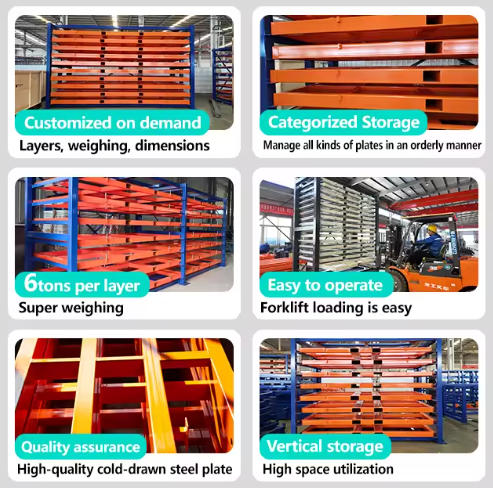

Layer customization based on material thickness proves essential. Furniture manufacturers storing 18mm and 25mm panels require different layer spacing than metal shops handling 2mm and 10mm sheet steel. The system accommodates this through adjustable mounting points on the frame uprights. Facilities can specify six layers for uniform materials or increase to eight layers for varied thicknesses.

Size customization follows practical formulas. Standard practice adds 500mm to both length and width beyond the maximum material dimensions. This tolerance prevents edge damage during loading and provides finger space for manual adjustment. A warehouse storing 2440×1220mm sheets would specify a 2940×1720mm drawer surface—ensuring adequate clearance without wasted space.

Safety Engineering Integration

Anti-pinch design features include physical gaps between drawer edges and frame members. Some implementations use recessed handle designs that prevent finger placement in closing paths. These aren’t afterthoughts—they’re engineered into the rail mounting system during manufacturing. Each drawer includes a mechanical stop preventing complete extraction unless deliberately released, protecting operators and materials from accidental drops.

The transparent label sleeve system enables visual management without opening drawers. Operators identify contents by material type, thickness, quantity, and job assignment. This reduces search time and prevents mispulls. In busy facilities, color-coding label backgrounds by material type creates instant recognition—blue for steel, green for aluminum, yellow for wood products.

Integration with Material Handling Equipment

While the system’s primary advantage is forklift-independent operation, it complements powered equipment for heavy loads. Gantry cranes position large steel plates onto extended drawers. The drawer front includes reinforced lips that support loads during partial extension, allowing crane operators to lower materials directly onto the drawer surface.

For upper layers beyond comfortable reach, matching ladder trucks provide safe access. These platform trucks lock to the rack frame, stabilizing the climbing surface. Platform height adjusts to drawer level, eliminating dangerous stretching or overreaching. This combination transforms vertical storage from a safety liability into an accessible asset.

Facility Implementation Results

A case study from a Midwest furniture manufacturer illustrates real impact. This facility stored 80,000 board feet of panel stock across 2,000 square meters. After installing drawer style board shelving, they condensed storage to 800 square meters while improving retrieval times by 65%. Material damage rates dropped from 12% to under 2%. Labor costs for material handling decreased by $45,000 annually—paying for the system in fourteen months.

Building material distributors report similar gains. A Texas-based supplier reduced sheet goods waste from 9% to 1.5% after implementing the system. The ability to store different drywall types in accessible drawers prevented the “stack search” damage that previously destroyed 15-20 sheets weekly. Their ROI realization period was eleven months.

Specification Matching for Application

Selecting the correct model requires analyzing material dimensions and weight. The HC-B4015-65 handles 4×1.5m sheets at 5 tons per layer—ideal for standard plywood and MDF storage. The HC-B4020-68’s 4×2m surface and 8-ton capacity suits metal fabrication shops handling large-format steel. The HC-B6020-610 serves heavy industrial applications with 6×2m sheets and 10-ton loads.

Customization extends beyond standard models. Facilities with unique requirements—such as extra-wide composite panels or unusually thick plate stacks—receive engineered solutions. The base frame design scales through reinforced uprights and upgraded rail systems, maintaining the same operational principles at higher load ratings.