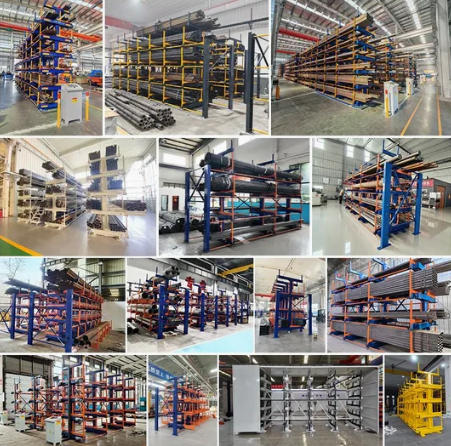

As a specialized cantilever rack manufacturer in China, we’ve developed revolutionary telescopic cantilever shelves to address persistent material storage issues. These rail-type long material storage racks represent a paradigm shift in how industries manage profiles, pipes, bars, and other elongated items. Our solutions combine engineering precision with practical innovation to create storage systems that are both efficient and adaptable.

Technical Specifications and Design

Core Structural Components

The telescopic cantilever metal sheet warehouse storage rack system integrates several key elements:

- Column pieces: The foundational vertical supports

- Fixed arms: Stationary structural components

- Movable arms: Adjustable extensions for material placement

- Stabilizing rods: Ensure structural rigidity during operation

- Transmission rods: Facilitate movement between arms

- Control end kits: Manage the extension/retraction process

Operational Classification

Our product line offers two distinct operational modes:

- Manual telescopic cantilever frame: Operated through mechanical controls requiring human input

- Electric telescopic cantilever frame: Automated system with motorized extension capabilities

Structural Engineering

The framework is constructed by assembling multiple column pieces with stabilizing rods. Each column unit features both fixed and movable arm components. When integrated, these create a comprehensive bracket structure capable of securely holding various long materials. This modular design allows for customized configurations based on specific storage requirements.

Advanced Storage Methodologies

Three-dimensional Storage Implementation

- Conceptual Foundation: By transitioning from traditional ground-level stacking to vertical storage using available height, we create a three-dimensional storage environment that maximizes space utilization.

- Operational Advantages: This approach delivers:

- Significant improvement in storage efficiency

- Reduced required storage area

- Lower overall storage costs

- Elimination of traditional stacking limitations

- Enhanced material accessibility

Visual Management System Integration

- Definition and Purpose: Visual management employs intuitive visual cues – including color coding and clear labeling – to organize storage activities. This method enhances productivity through immediate visual recognition.

- Industry Challenges: Many facilities struggle with:

- Material classification difficulties due to mixed storage

- Overcrowding leading to obscured labels

- Inefficient retrieval processes

- Increased labor requirements

- Extended material handling times

- Our Innovative Solution: The telescopic cantilever system addresses these issues by:

- Implementing compartmentalized storage

- Allowing independent access to each section

- Maintaining clear labeling for every storage unit

- Resulting in faster retrieval times

- Reducing personnel involvement

- Delivering a “fast, accurate, economical” storage experience

Independent Layer Access Technology

- Traditional Storage Problems: Conventional methods often result in:

- Mixed storage of different material types

- Difficulty in locating specific items

- Inefficient picking processes

- Limited access to lower-level materials

- Increased risk of material damage

- Our Breakthrough Approach: The system features:

- Multiple independent storage layers

- Classified storage by material type

- Easy access to all items regardless of position

- Improved warehouse circulation efficiency

- Enhanced picking accuracy

- Reduced material handling time

Low Access Channel Requirements

- Conventional Warehouse Limitations: Traditional design typically requires:

- Dedicated access channels between shelves

- Significant space allocation for forklift operations

- Height restrictions for equipment access

- Increased operational costs

- Our Space-saving Innovation: The telescopic cantilever system enables:

- Vertical storage and retrieval operations

- Minimal space requirements (only telescopic channels and personnel standing areas)

- Elimination of high-level access channels (above 6 meters)

- Substantial storage area savings

- Reduced operational costs

Material Protection Features

Comprehensive Safeguarding System

- Ground Storage Issues: Traditional methods often lead to:

- Material loss due to improper handling

- Rust formation from ground contact

- Deformation from improper stacking

- Increased material waste

- Our Protective Solutions: The system provides:

- Multiple movable arm structures with side guards

- Layered independent storage

- Enhanced material protection

- Reduced material damage

- Prevention of loss from improper handling

- Improved material integrity

Industry Applications and Benefits

Broad Industrial Use

The telescopic cantilever frame is extensively utilized in:

- Machinery manufacturing industry: For storing various metal components

- Pipe and profile manufacturing industry: Ideal for long-form product storage

- General long material storage: Suitable for all types of profiles, pipes, and bars

Customized Solutions

As a leading cantilever rack manufacturer in China, we offer:

- Tailored designs for specific material types

- Custom configurations based on facility dimensions

- Specialized solutions for unique industrial requirements

- Comprehensive technical support

Why Our Solutions Stand Out

- Space Optimization: Maximizes vertical space utilization

- Operational Efficiency: Improves material handling processes

- Cost Reduction: Lowers storage expenses through smart design

- Material Protection: Ensures product integrity during storage

- Flexibility: Adaptable to various material types and sizes

- Innovation: Incorporates latest storage technology advancements

- Quality: Built to rigorous manufacturing standards

Conclusion

As a professional cantilever rack manufacturer in China, we’ve developed innovative telescopic cantilever shelves that redefine long material storage. Our rail-type long material storage rack systems offer comprehensive benefits including three-dimensional storage capability, visual management enhancements, independent layer access, minimal space requirements, and superior material protection. These features make our products indispensable for modern manufacturing and processing facilities seeking to optimize their storage operations.

For industries dealing with profiles, pipes, bars, and other long materials, our telescopic cantilever shelves represent the future of efficient, cost-effective, and space-saving storage solutions. Contact us today to discover how our innovative storage systems can transform your material handling operations.