Automatic Loading and Unloading Systems for Fiber Laser Cutting Machines

In the competitive world of sheet metal fabrication, the integration of Automatic Loading and Unloading Systems with Fiber Laser Cutting Machines has become a game-changer. These sophisticated systems are designed to maximize productivity, minimize downtime, and reduce labor costs by automating material handling processes. As the industry shifts towards Industry 4.0 standards, the demand for intelligent and efficient manufacturing solutions has never been higher.

In the competitive world of sheet metal fabrication, the integration of Automatic Loading and Unloading Systems with Fiber Laser Cutting Machines has become a game-changer. These sophisticated systems are designed to maximize productivity, minimize downtime, and reduce labor costs by automating material handling processes. As the industry shifts towards Industry 4.0 standards, the demand for intelligent and efficient manufacturing solutions has never been higher.

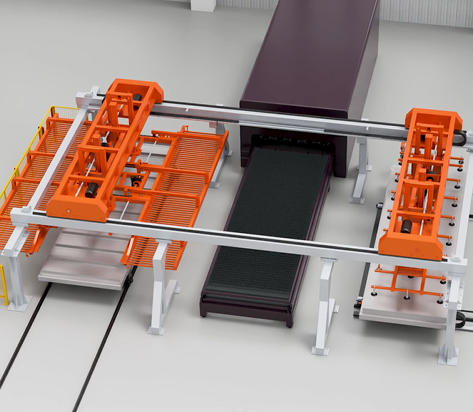

Core Components of an Automated Production Unit

Three-Dimensional Storage Warehouse

The foundation of any automated system is its storage capacity. The three-dimensional storage warehouse serves as the central hub for raw material inventory management. With capacities ranging from 8 to 13 floors and load per layer from 3T to 5T, these warehouses optimize space utilization while ensuring quick access to materials.

Double-Sided Gantry Truss System

The gantry truss acts as the backbone of material transportation. The double-sided design allows for simultaneous loading and unloading operations, significantly improving workflow efficiency. Made from high-strength aluminum alloys, these trusses offer durability while maintaining lightweight characteristics.

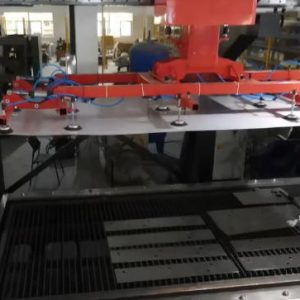

Loading and Unloading Truss Manipulators

These intelligent robotic arms are equipped with specialized end-effectors:

Suction cups for raw material handling

Rakes for finished sheet removal

Vacuum generators for secure material grip

Double-Layer Finished Material Truck

An innovative feature of these systems is the double-layer finished material truck, which doubles the storage capacity for cut parts without increasing footprint. This design is particularly beneficial for high-volume production environments.

PLC Control System

The brain of the operation, the PLC control system coordinates all movements with precision timing. It interfaces with the laser cutting machine’s CNC system to ensure seamless material flow and production synchronization.

Technical Specifications and Performance Metrics

Machine Configurations

Available in multiple size options:

3015/4015/4020/6015/6020/6025mm work areas

adaptable to various production scales

Material Handling Capabilities

Maximum load capacity: 300KG-3000KG

Air consumption: 1.5m³/min

Air source requirements: 0.6-0.7Mpa

Precision and Speed

Positioning accuracy: ±1mm

Repeatability: ±1mm

Maximum speed: 25m/min

Scope of work: 3200mm-5200mm

Electrical Specifications

Rated voltage: 220v 50hz/60hz

Air supply pressure: 0.55mPa

Machine weight: 1000kg

Advanced Features and Benefits

Enhanced Productivity

The system’s fast material exchange time of 65 seconds ensures minimal downtime between cutting cycles. This optimization allows for:

Increased machine utilization rates

Reduced idle time

Higher overall equipment effectiveness (OEE)

Intelligent Material Management

Integration with laser cutting machines enables:

Automatic material storage management

Smart retrieval based on cutting schedules

Real-time inventory tracking

Mechanical Advantages

Standard parallel cylinder design reduces wear on transmission parts

Extended equipment lifespan due to optimized mechanical components

Flexible positioning capabilities for diverse material sizes

Operational Flexibility

Vertical and horizontal adaptability for various production layouts

Support for small parts cutting with precision handling

Compatibility with electric vehicles for smart factory integration

Control System Innovations

Bus system architecture for enhanced communication

Absolute value motors for precise positioning

Strong anti-interference capabilities

No need for return to origin after startup

Faster transmission speeds

Standard teach pendant for easy programming

Remote control functionality

System Integration and Expansion Options

Multi-Beam Loading and Unloading Rack

The self-developed new frame structure supports:

Double beam configurations

Multi-beam arrangements for enhanced load capacity

Slider guide rail transmission for synchronized production

Unattended Operation Capabilities

By integrating with tower silos and material storage systems, the solution enables:

24/7 continuous production

Reduced labor requirements

Improved workplace safety

Multi-Equipment Support

A single loading and unloading system can manage operations for multiple cutting machines, providing:

Space optimization in workshops

Energy efficiency through centralized control

Reduced operational costs

Industry Applications and Use Cases

Automotive Manufacturing

High-volume sheet metal processing

Precision component production

Just-in-time manufacturing support

Aerospace Components

Large-scale panel cutting

Complex geometry processing

Quality-critical applications

Architectural Metalwork

Customized facade elements

Structural components

Ornamental metalwork

Electronics Enclosures

Small parts production

High-precision cutting

Clean room compatible operations

Implementation Considerations

Factory Layout Optimization

Space requirements for integrated systems

Material flow planning

Workstation ergonomics

Power and Air Supply Needs

Electrical infrastructure assessment

Compressed air system requirements

Backup power considerations

Maintenance Requirements

Preventive maintenance schedule

Wear parts replacement

System calibration procedures

Training Needs

Operator training programs

Maintenance technician training

System integration specialists

Future Trends and Innovations

Smart Factory Integration

IoT connectivity for real-time monitoring

Predictive maintenance capabilities

AI-driven production optimization

Hybrid Material Handling

Multi-material processing capabilities

Adaptive end-effector technology

Automated quality inspection integration

Sustainability Features

Energy recovery systems

Recycled material handling

Carbon footprint reduction strategies

Conclusion

The Automatic Loading and Unloading System represents the forefront of innovation in sheet metal fabrication technology. By seamlessly integrating with Fiber Laser Cutting Machines, these systems offer unparalleled productivity gains, operational efficiency, and quality improvements. As manufacturing continues to evolve towards complete automation, these solutions will become increasingly essential for competitive production environments. The investment in such systems not only enhances current production capabilities but also future-proofs operations against industry advancements.

Factory

Hot Selling Machines

-

Heavy Duty Sheet Metal Storage Racks

Intelligent Production Line CNC Automated Storage Rack: Precision Meets Automation

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drawer-Style Sliding Sheet Metal Storage Rack – Efficient & Safe Material Handling

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Design for Steel Plate Storage with Heavy Duty Drawer Type Sheet Metal Rack Storage System

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Rack for Heavy Plates and Molds: Durable, Efficient Storage for Industrial Applications

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drive-In Pallet Rack Alternative: Space-Saving Drawer-Type Sheet Metal Storage with Automated Retrieval Compatibility

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Drawer Type Plate Shelves Warehouse Rack System for Industrial Metal Storage – 3-Ton Capacity per Layer

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Warehouse Storage System: Customizable Solutions for Metal Plate & Industrial Storage

Read moreRated 0 out of 5 -

Automated Storage Systems

Smart Fixed Profile Stereo Warehouse: Cost-Effective Automation for Small to Mid-Sized Fabrication Shops

Read moreRated 0 out of 5

Related products

Related products

-

Sheet Metal Handling Equipment

Heavy-Duty Rotary Loading Robot for 100KG/200KG/300KG – The Ultimate Solution for Industrial Plate Handling

Read moreRated 0 out of 5 -

Sheet Metal Handling Equipment

Laser Cutting with Gantry Loading and Unloading System of Smart Laser Automation

Read moreRated 0 out of 5