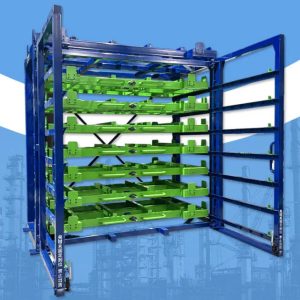

Custom Storage Rack for 6-Meter Plates and Heavy Loads

This operational challenge requires a structural response. Herochu Custom Storage Racks for 6-Meter Plates and Heavy Loads are engineered specifically for this reality. We transform the chaotic geometry of oversized inventory into an organized system that protects your material investment while optimizing workflow efficiency. Starting at $5,499, this custom solution redefines heavy-duty storage through intelligent design and precision engineering.

Herochu Custom Storage: A Blueprint for Heavy-Duty Material Management

Every workshop has its hidden geometries. For structural fabricators and industrial manufacturers, this geometry is defined by oversized materials—6-meter mild steel plates, architectural aluminum extrusions, and heavy-gauge alloy sheets that refuse to conform to standard storage solutions. The common industry practice of floor stacking or makeshift racking creates a cascade of inefficiencies: inaccessible inventory, material degradation, and dangerous working conditions. When your materials weigh thousands of kilograms and span over six meters, conventional shelving systems become not just inadequate, but a liability.

This operational challenge requires a structural response. Herochu Custom Storage Racks for 6-Meter Plates and Heavy Loads are engineered specifically for this reality. We transform the chaotic geometry of oversized inventory into an organized system that protects your material investment while optimizing workflow efficiency. Starting at $5,499, this custom solution redefines heavy-duty storage through intelligent design and precision engineering.

The Physics of Oversized Storage: A Structural Analysis

The challenge of storing 6-meter materials extends beyond simple space considerations. When heavy plates rest on uneven surfaces or inadequate supports, they experience differential loading that leads to permanent deformation. This warping becomes immediately apparent during precision cutting operations, causing laser nozzle collisions, plasma cutter deflection, and compromised dimensional accuracy. Similarly, beams and extrusions stored without proper lateral support develop twists and bows that require costly straightening before fabrication.

Our engineering approach addresses these material dynamics at the structural level. Each custom rack functions as a continuous support system designed to maintain material integrity throughout the storage cycle. By distributing weight evenly across the entire length of the material, we eliminate the stress concentrations that cause deformation. This isn’t merely storage—it’s preservation of material flatness and dimensional stability, ensuring that what goes into the rack comes out ready for precision fabrication.

Architecture of Strength: Engineering Principles in Practice

The difference between adequate and exceptional storage lies in the details of construction. Our custom racks incorporate several critical design elements that distinguish them from standard industrial shelving:

Load-Bearing Architecture: Utilizing high-grade Q235B steel with a minimum yield strength of 235 MPa, we construct frames that function as integrated structural systems rather than simple storage containers. The crossbeam configuration follows engineered load paths that channel weight directly to reinforced vertical supports, preventing the rack deflection that compromises long-term stability.

Dynamic Access Systems: For facilities requiring frequent material selection, our roll-out drawer systems employ industrial-grade bearing mechanisms rated for continuous heavy-duty use. These aren’t standard drawer slides but engineered carriage systems that maintain alignment and smooth operation under extreme loads. The result is safe, effortless access to even the heaviest plates without forklift assistance.

Modular Configurability: Unlike fixed-dimension shelving, our custom approach allows for compartmentalization based on material profiles. A single rack might incorporate sections for 6-meter plates alongside dedicated spaces for shorter stock, beams, or specialized materials. This tailored organization eliminates wasted space while creating logical inventory groupings that match production workflows.

From Raw Materials to Refined Systems: The Customization Process

The true value of custom storage emerges during the design phase. Our process begins with a comprehensive analysis of your operational requirements:

Material Profiling: We document every material type, dimension, weight, and handling frequency. This includes understanding not just current inventory but anticipated future needs, ensuring the system accommodates business growth.

Spatial Integration: Our designers evaluate your facility’s unique characteristics—overhead crane clearances, column spacing, floor load capacities, and traffic patterns. The final design optimizes storage density while maintaining necessary access corridors and safety zones.

Workflow Synchronization: We analyze how materials move through your facility from receiving to fabrication to shipping. The storage system becomes an active component in this flow, positioned to minimize handling and reduce transit distances between storage and workstations.

This collaborative design process ensures the final installation functions as an extension of your production environment rather than an afterthought.

The Operational Mathematics: Calculating Return on Investment

Quantifying the benefits of a custom storage system reveals compelling financial returns across multiple dimensions:

Space Reclamation: By converting horizontal floor stacks into vertical storage towers, facilities typically recover 40-60% of previously unusable floor space. This reclaimed area can accommodate additional workstations, equipment, or material staging zones, effectively increasing production capacity without facility expansion.

Labor Efficiency: The average fabricator spends 15-20 minutes locating and extracting a specific plate from floor stacks. Our organized systems reduce this to under 5 minutes—a 75% reduction in retrieval time that compounds across hundreds of annual retrievals, representing thousands of recovered labor hours.

Material Preservation: Eliminating warping, edge damage, and surface contamination from floor storage directly preserves material value. For facilities handling premium alloys or pre-finished materials, this preservation alone can justify the system investment within 12-18 months.

Safety Enhancement: Organized storage dramatically reduces the forklift maneuvering, material shifting, and precarious access that contribute to workplace incidents. The resulting reduction in downtime, insurance costs, and regulatory compliance issues delivers ongoing financial benefits.

Industry-Specific Applications: Beyond General Storage

The versatility of custom storage solutions extends across multiple industrial sectors:

Structural Steel Fabrication: Storing beams, channels, and heavy plate up to 8 meters in length with weight capacities exceeding 8,000 kg per level. Specialized configurations accommodate irregular shapes while maintaining structural integrity.

Architectural Metals: Dedicated systems for finished materials like anodized aluminum, pre-painted panels, and specialty glass that require scratch-free handling and segregated storage to prevent surface damage.

Heavy Equipment Manufacturing: Solutions for oversized plate stock used in machinery bases, crane components, and industrial enclosures where material flatness directly impacts final assembly tolerances.

Aerospace and Defense: Secure storage configurations for high-value alloys with chain-of-custody controls and environmental protection features.

Integration with Modern Manufacturing Systems

Today’s industrial storage solutions must interface seamlessly with broader production systems. Our custom racks incorporate features that support technological integration:

Inventory Management Compatibility: Design elements that facilitate barcode/RFID tagging and automated inventory tracking systems, creating real-time visibility into material location and availability.

Material Handling Synchronization: Engineering that accommodates automated retrieval systems, overhead crane access points, and forklift interface standards, ensuring the storage system functions as an integrated component in automated material flow.

Scalability and Reconfiguration: Modular construction principles that allow system expansion or reconfiguration as production needs evolve, protecting your investment against changing business requirements.

Engineering Certification and Quality Assurance

Every Herochu Custom Storage System carries the validation of CE, UE, and ISO 9001 certifications. This certification framework ensures:

-

Structural calculations verified by independent engineering review

-

Manufacturing processes following documented quality control protocols

-

Materials traceability from source to finished installation

-

Safety factors exceeding industry standards for heavy industrial applications

This certification framework provides not just compliance but verifiable assurance of system performance and durability.

From Installation to Optimization: The Implementation Process

Our service extends beyond fabrication to complete system implementation:

Pre-Installation Planning: Detailed site preparation guidelines, foundation requirements, and utility coordination to ensure seamless installation.

Professional Installation: Factory-trained technicians who assemble, level, and secure the complete system, verifying all components meet specification requirements.

Operator Training: Comprehensive instruction on safe loading procedures, weight distribution principles, and maintenance protocols specific to your configuration.

Post-Installation Support: Ongoing technical support, scheduled maintenance inspections, and engineering consultations for future modifications.

The Strategic Perspective: Storage as Competitive Advantage

In competitive manufacturing environments, efficiency advantages compound. The organization, accessibility, and preservation provided by custom storage systems create measurable competitive differentiation:

Reduced Lead Times: Immediate access to materials accelerates production scheduling and improves responsiveness to urgent orders.

Enhanced Quality Control: Protected materials maintain specifications throughout storage, reducing rework and improving final product quality.

Professional Presentation: Organized storage areas impress clients and auditors, demonstrating operational excellence that builds business credibility.

Scalable Operations: Systems designed with growth in mind accommodate business expansion without disruptive storage reorganizations.

Conclusion: The Foundation of Efficient Fabrication

The relationship between material management and manufacturing efficiency is direct and measurable. Disorganized storage creates friction at every production stage, while organized systems create fluid workflows that amplify overall productivity. Herochu Custom Storage Racks represent more than a capital purchase—they constitute infrastructure investment that delivers continuous returns through operational improvement.

For fabricators and manufacturers working with oversized, heavy materials, the storage question is fundamental. We provide the engineered solution that transforms this fundamental requirement from a persistent challenge into a structured advantage.

Begin transforming your material management today. Contact our engineering team to schedule a facility assessment and receive a customized proposal that addresses your specific operational requirements and material profiles.

Factory

Hot Selling Machines

-

Heavy Duty Sheet Metal Storage Racks

Intelligent Production Line CNC Automated Storage Rack: Precision Meets Automation

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drawer-Style Sliding Sheet Metal Storage Rack – Efficient & Safe Material Handling

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Design for Steel Plate Storage with Heavy Duty Drawer Type Sheet Metal Rack Storage System

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Rack for Heavy Plates and Molds: Durable, Efficient Storage for Industrial Applications

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drive-In Pallet Rack Alternative: Space-Saving Drawer-Type Sheet Metal Storage with Automated Retrieval Compatibility

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Drawer Type Plate Shelves Warehouse Rack System for Industrial Metal Storage – 3-Ton Capacity per Layer

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Warehouse Storage System: Customizable Solutions for Metal Plate & Industrial Storage

Read moreRated 0 out of 5 -

Automated Storage Systems

Smart Fixed Profile Stereo Warehouse: Cost-Effective Automation for Small to Mid-Sized Fabrication Shops

Read moreRated 0 out of 5

Related products

Related products

-

Heavy Duty Sheet Metal Storage Racks

Revolutionize Material Handling with Forklift-Compatible Sheet Metal Racks

Read moreRated 0 out of 5