Dual‑Tower Sheet Metal Storage Warehouse

As global competition intensifies and customer demands grow more complex, metal fabricators face mounting pressure to do more with less: less space, less labor, less waste, and less time. The Dual‑Tower Sheet Metal Storage Warehouse answers this challenge head-on by reimagining how sheet metal is stored, accessed, and managed throughout the production lifecycle. This isn’t just another rack—it’s a fully integrated, intelligent storage ecosystem engineered for the realities of modern fabrication.

Dual‑Tower Sheet Metal Storage Warehouse – The Future of High-Density, Automated Racking for Metal Fabricators

As global competition intensifies and customer demands grow more complex, metal fabricators face mounting pressure to do more with less: less space, less labor, less waste, and less time. The Dual‑Tower Sheet Metal Storage Warehouse answers this challenge head-on by reimagining how sheet metal is stored, accessed, and managed throughout the production lifecycle. This isn’t just another rack—it’s a fully integrated, intelligent storage ecosystem engineered for the realities of modern fabrication.

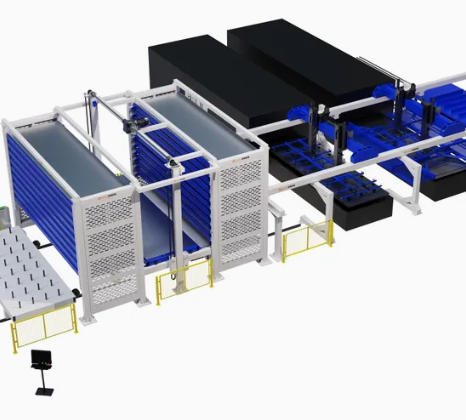

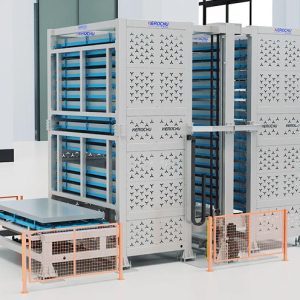

At its foundation, the system leverages a dual-tower vertical lift design that doubles usable storage capacity without increasing floor occupancy. By placing two high-bay towers side by side with a shared retrieval mechanism, the configuration achieves 68 discrete storage positions in just 280 square feet. Each position supports up to 6,600 lbs, enabling total system capacity of over 224 tons—an unprecedented density for sheet metal storage. This capability allows shops to consolidate raw material inventories that would otherwise require multiple aisles of static racking or off-site warehousing.

The engineering behind the Dual‑Tower Sheet Metal Storage Warehouse reflects years of field-tested refinement. Movement is handled by a chain-driven lift carriage running along industrial-grade linear guide rails, ensuring smooth, vibration-free operation even under maximum load. The vertical travel speed of 9 meters per minute—paired with a 12 m/min inlet/outlet speed—ensures rapid material turnover, critical in high-mix environments where job changeovers happen hourly. Unlike older VLMs that suffer from slow acceleration or mechanical lag, this system maintains consistent performance across thousands of cycles.

Crucially, the system accommodates a wide spectrum of sheet formats. Whether your workflow involves 4′ x 8′ aluminum sheets for architectural panels, 5′ x 10′ stainless for food processing equipment, or 6′ x 12′ carbon steel plates for heavy machinery, the storage bays can be configured accordingly. Optional plate support systems—including edge guides, anti-slip pads, and segmented cradles—ensure stability during both storage and transit, protecting delicate finishes and preventing warping in thin-gauge materials.

But perhaps the greatest transformation occurs on the shop floor. Operators no longer waste time searching for materials, waiting for forklifts, or risking injury while maneuvering heavy sheets. Instead, they initiate a retrieval with a button press and receive the exact plate they need—delivered cleanly, safely, and at an ideal working height. This not only boosts morale but also enhances throughput: studies show that ergonomic material delivery can reduce setup times by up to 40%.

From a safety standpoint, the system is a game-changer. Manual sheet handling often involves awkward postures, pinch points, and uncontrolled sliding—all leading causes of musculoskeletal disorders. Forklift operations introduce additional risks: collisions, tip-overs, and visibility blind spots. The Dual‑Tower system eliminates both scenarios by enclosing the entire process within a secure, automated structure. Compliance with ISO 13857 (safety of machinery) and ANSI MH27.1 (VLM standards) is built into the design, giving EHS managers peace of mind.

Moreover, the system supports sustainability goals. By maximizing vertical space, it reduces the need for warehouse expansions—which in turn lowers construction-related emissions and land use. Efficient material handling also minimizes energy consumption compared to repeated forklift trips. And because fewer sheets are damaged or scrapped, raw material utilization improves, aligning with circular economy principles.

For businesses evaluating automation, scalability matters. The Dual‑Tower model is ideal for mid-to-large operations, but a single-tower version offers identical technology in a smaller form factor—perfect for job shops, prototyping labs, or facilities with lower ceilings. Both variants share the same control architecture, making future upgrades straightforward.

In an industry where margins are tight and agility is essential, the Dual‑Tower Sheet Metal Storage Warehouse delivers more than convenience—it delivers competitive advantage. It transforms raw material storage from a passive cost center into an active enabler of lean, safe, and responsive manufacturing. As automation becomes less a luxury and more a baseline expectation, this system stands as a benchmark in Automated Warehouse Racking Solutions for the metalworking world.

Factory

Hot Selling Machines

-

Heavy Duty Sheet Metal Storage Racks

Intelligent Production Line CNC Automated Storage Rack: Precision Meets Automation

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drawer-Style Sliding Sheet Metal Storage Rack – Efficient & Safe Material Handling

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Design for Steel Plate Storage with Heavy Duty Drawer Type Sheet Metal Rack Storage System

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Rack for Heavy Plates and Molds: Durable, Efficient Storage for Industrial Applications

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drive-In Pallet Rack Alternative: Space-Saving Drawer-Type Sheet Metal Storage with Automated Retrieval Compatibility

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Drawer Type Plate Shelves Warehouse Rack System for Industrial Metal Storage – 3-Ton Capacity per Layer

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Warehouse Storage System: Customizable Solutions for Metal Plate & Industrial Storage

Read moreRated 0 out of 5 -

Automated Storage Systems

Smart Fixed Profile Stereo Warehouse: Cost-Effective Automation for Small to Mid-Sized Fabrication Shops

Read moreRated 0 out of 5

Related products

Related products

-

Automation Sheet Metal Material Warehouse

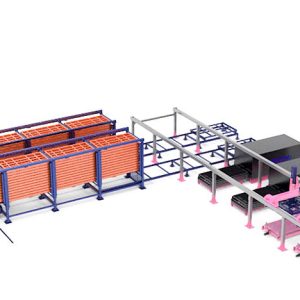

Twin-Tower, Four-Aisle Metal Plate Storage and Side-Discharge Rack System with Dual-Beam Manipulator

Read moreRated 0 out of 5 -

Automation Sheet Metal Material Warehouse

Intelligent Sheet Metal Storage System FAQ and Specification Guide

Read moreRated 0 out of 5 -

Automation Sheet Metal Material Warehouse

Customized Steel Electric Telescopic Automatic Loading and Unloading System

Read moreRated 0 out of 5 -

Automation Sheet Metal Material Warehouse

Double-Tower Sheet Material Automated Storage and Retrieval System

Read moreRated 0 out of 5