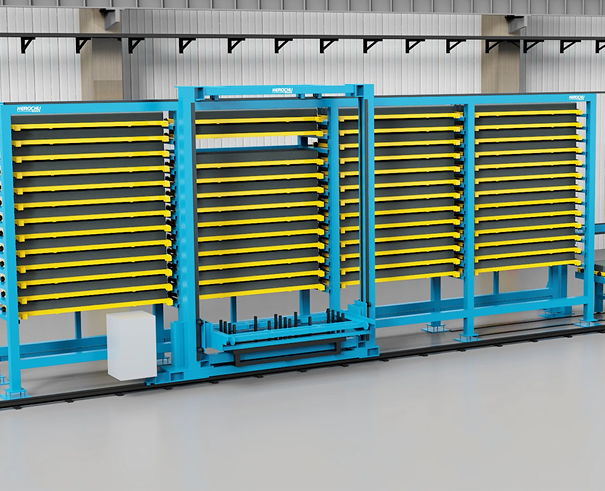

Four-Row Metal Plate Storage Rack

In today’s fast-paced metal fabrication and manufacturing environments, efficiency isn’t just a goal—it’s a necessity. One of the most overlooked yet impactful upgrades you can make is investing in a four-row metal plate storage rack. Designed specifically for heavy-duty sheet metal handling, this system transforms chaotic floor layouts into streamlined, high-performance workspaces.

Four-Row Metal Plate Storage Rack – Optimize Your Workshop with Smart Vertical Organization

In today’s fast-paced metal fabrication and manufacturing environments, efficiency isn’t just a goal—it’s a necessity. One of the most overlooked yet impactful upgrades you can make is investing in a four-row metal plate storage rack. Designed specifically for heavy-duty sheet metal handling, this system transforms chaotic floor layouts into streamlined, high-performance workspaces.

Why Traditional Storage Falls Short

Many shops still rely on stacking metal plates directly on the floor or using outdated A-frame racks. While these methods may seem cost-effective at first glance, they come with hidden expenses: increased risk of material damage, worker injuries, wasted time searching for specific gauges, and inefficient use of valuable floor space. Over time, these inefficiencies erode profitability and slow down production cycles.

The four-row metal plate storage rack addresses these pain points head-on by combining structural integrity with intelligent design.

Key Features That Drive Real-World Value

1. Rapid Retrieval Without Compromise

Each rack features four vertical rows of removable cassettes, allowing operators to access any sheet in seconds—without disturbing adjacent materials. This quick-access capability translates directly into higher productivity. When your team spends less time hunting for materials and more time cutting, welding, or assembling, output increases while labor costs decrease.

2. Space-Saving Vertical Architecture

Unlike horizontal stacking, which consumes large floor footprints, the four-row design leverages vertical space. This modular approach reclaims up to 60% of floor area previously lost to disorganized piles. In urban facilities or leased spaces where square footage equals dollars, this spatial efficiency is a game-changer.

3. Enhanced Safety Through Secure Containment

Every cassette is engineered from heavy-gauge steel to securely hold metal plates of varying thicknesses and dimensions. Sheets remain upright and immobilized, eliminating the risk of slippage, edge damage, or accidental falls. Additionally, clear pathways are maintained throughout the workspace, reducing trip hazards and creating a safer environment compliant with OSHA standards.

4. Organized by Size, Type, and Batch

Custom labeling options allow you to categorize cassettes by material grade (e.g., stainless steel, aluminum, carbon steel), thickness (from 16-gauge to 1-inch plate), or project-specific batches. This level of organization minimizes picking errors during production runs—a common source of costly rework.

5. Transparent Inventory Visibility

With open-front cassettes, visual stock checks become effortless. Supervisors can instantly assess inventory levels without moving materials or consulting digital logs. This transparency supports just-in-time ordering strategies, preventing both overstocking (which ties up capital) and unexpected shortages (which halt production).

Built for Long-Term ROI

While the upfront investment in a four-row metal plate storage rack may seem significant, its return on investment becomes evident within months. Consider:

- Labor savings: Reduced handling time per sheet.

- Material preservation: Less dinging, scratching, or warping extends usable life.

- Space optimization: Freed-up floor area can be repurposed for additional machinery or workflow stations.

- Scalability: Modular units can be expanded as your business grows.

Moreover, because the system uses standardized components, maintenance is minimal, and replacement parts are readily available.

Ideal Applications Across Industries

This storage solution excels in:

- Metal fabrication shops managing diverse plate inventories

- Aerospace and automotive suppliers requiring precision material handling

- Construction firms storing structural steel plates on-site

- HVAC and industrial equipment manufacturers dealing with frequent material changes

Final Thoughts

A four-row metal plate storage rack isn’t just shelving—it’s a strategic asset that enhances safety, organization, and profitability. By replacing haphazard stacking with a purpose-built vertical system, you empower your team to work smarter, faster, and safer. In an industry where margins are tight and competition fierce, such operational advantages can be the difference between stagnation and growth.

Invest in order. Invest in efficiency. Invest in a future-proof workshop with the four-row metal plate storage rack.

Factory

Hot Selling Machines

-

Heavy Duty Sheet Metal Storage Racks

Intelligent Production Line CNC Automated Storage Rack: Precision Meets Automation

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drawer-Style Sliding Sheet Metal Storage Rack – Efficient & Safe Material Handling

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Design for Steel Plate Storage with Heavy Duty Drawer Type Sheet Metal Rack Storage System

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Rack for Heavy Plates and Molds: Durable, Efficient Storage for Industrial Applications

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drive-In Pallet Rack Alternative: Space-Saving Drawer-Type Sheet Metal Storage with Automated Retrieval Compatibility

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Drawer Type Plate Shelves Warehouse Rack System for Industrial Metal Storage – 3-Ton Capacity per Layer

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Warehouse Storage System: Customizable Solutions for Metal Plate & Industrial Storage

Read moreRated 0 out of 5 -

Automated Storage Systems

Smart Fixed Profile Stereo Warehouse: Cost-Effective Automation for Small to Mid-Sized Fabrication Shops

Read moreRated 0 out of 5

Related products

Related products

-

Heavy Duty Sheet Metal Storage Racks

Heavy Duty Forklift steel plates Storage Rack

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy Duty Forklift Board Storage Rack

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy Duty Forklift Sheet Metal Storage Rack by Herochu

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sheet Metal Racking System That Works as Hard as Your Team

Read moreRated 0 out of 5