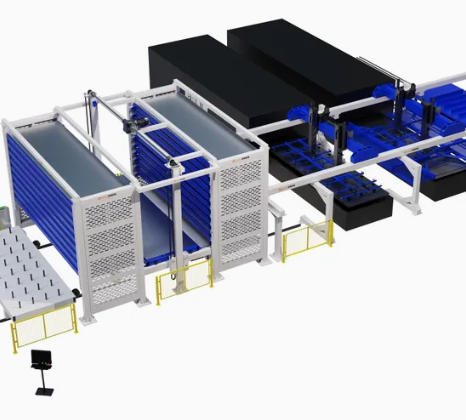

Gantry Robot Auto Load System for Laser Cutter

The Gantry Robot Auto Load System for Laser Cutter integrates several critical components to form a complete automated sheet metal production unit:

- Laser Cutting Machine with Composite Truss Manipulator: The core processing unit equipped with loading and unloading capabilities.

- Double-Layer Electric Exchange Material Car: Enables continuous material supply without interrupting production.

- CNC Control System: The brain of the operation, coordinating all movements and processes.

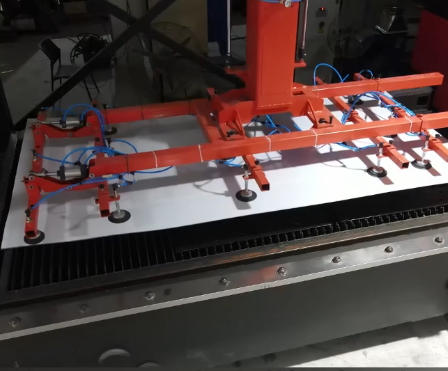

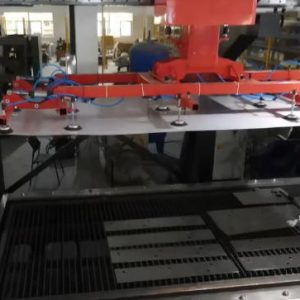

- Vacuum Control System: Ensures secure grip and precise handling of materials.

- Advanced Sensors and Vision Systems: For real-time monitoring and quality control.

Gantry Robot Auto Load System for Laser Cutter: A Comprehensive Solution

System Architecture and Components

The Gantry Robot Auto Load System for Laser Cutter integrates several critical components to form a complete automated sheet metal production unit:

- Laser Cutting Machine with Composite Truss Manipulator: The core processing unit equipped with loading and unloading capabilities.

- Double-Layer Electric Exchange Material Car: Enables continuous material supply without interrupting production.

- CNC Control System: The brain of the operation, coordinating all movements and processes.

- Vacuum Control System: Ensures secure grip and precise handling of materials.

- Advanced Sensors and Vision Systems: For real-time monitoring and quality control.

Technical Specifications

| Parameter | Value Range |

|---|---|

| Working Area (mm) | 3015/4015/4020/4025 |

| Maximum Load (kg) | 100-500 |

| Skip Load Capacity (t) | Up to 3 |

| Air Consumption (m³/min) | 1.5 |

| Air Source Pressure (Mpa) | 0.6-0.7 |

Operational Workflow

- Material Preparation: Sheets are selected, cleaned, and placed on the loading platform.

- Tool Assembly: specialized loading and unloading tools are installed and verified.

- Automated Loading: The system precisely grabs and transports materials to the cutting area.

- Cutting Process: Operators monitor progress through a comprehensive control system.

- Automated Unloading: Finished products are moved to the unloading area with care.

- Quality Inspection: Final verification of dimensional accuracy and cutting quality.

Factory

Hot Selling Machines

-

Heavy Duty Sheet Metal Storage Racks

Intelligent Production Line CNC Automated Storage Rack: Precision Meets Automation

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drawer-Style Sliding Sheet Metal Storage Rack – Efficient & Safe Material Handling

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Design for Steel Plate Storage with Heavy Duty Drawer Type Sheet Metal Rack Storage System

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Rack for Heavy Plates and Molds: Durable, Efficient Storage for Industrial Applications

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drive-In Pallet Rack Alternative: Space-Saving Drawer-Type Sheet Metal Storage with Automated Retrieval Compatibility

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Drawer Type Plate Shelves Warehouse Rack System for Industrial Metal Storage – 3-Ton Capacity per Layer

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Warehouse Storage System: Customizable Solutions for Metal Plate & Industrial Storage

Read moreRated 0 out of 5 -

Automated Storage Systems

Smart Fixed Profile Stereo Warehouse: Cost-Effective Automation for Small to Mid-Sized Fabrication Shops

Read moreRated 0 out of 5

Related products

Related products

-

Sheet Metal Handling Equipment

Heavy-Duty Rotary Loading Robot for 100KG/200KG/300KG – The Ultimate Solution for Industrial Plate Handling

Read moreRated 0 out of 5 -

Sheet Metal Handling Equipment

Innovative Material Handling Solutions: The Servo Swing Arm Manipulator for CNC Operations

Read moreRated 0 out of 5 -

Sheet Metal Handling Equipment

Steel Plate Material Handling Equipment for Modern Manufacturing

Read moreRated 0 out of 5