Heavy Duty Drawer Type Sheet Metal Racks – Maximize Floor Efficiency Without Sacrificing Access

In metal fabrication, every square foot counts—and so does every minute of machine uptime. Yet too many shops still rely on floor stacking, static pallet racks, or makeshift shelving to store sheet metal, creating bottlenecks that slow production, increase labor costs, and raise safety risks. The solution? Herochu’s Heavy Duty Drawer Type Sheet Metal Racks—engineered storage systems that combine industrial strength with full-access roll-out functionality.

In metal fabrication, every square foot counts—and so does every minute of machine uptime. Yet too many shops still rely on floor stacking, static pallet racks, or makeshift shelving to store sheet metal, creating bottlenecks that slow production, increase labor costs, and raise safety risks. The solution? Herochu’s Heavy Duty Drawer Type Sheet Metal Racks—engineered storage systems that combine industrial strength with full-access roll-out functionality.

Standing at a standard 84 inches (7 feet) tall, these all-welded steel racks are built to handle the rigors of daily use in high-volume environments. Each drawer supports up to 5,500 lbs (2.5 metric tons) and extends 100% on four precision roller bearings, giving operators complete visibility and access to every sheet—no digging, no shifting, no wasted time.

Why Traditional Racking Falls Short

Conventional warehouse shelving often forces a trade-off: either store material densely (but lose accessibility) or keep it accessible (but waste space). Forklift-dependent systems add another layer of complexity—requiring dedicated drivers, wide aisles, and careful coordination during material changeovers. In contrast, Herochu’s drawer racks can be loaded and unloaded using an overhead crane, eliminating the need for floor-level equipment and shrinking aisle widths by up to 40%.

This is especially valuable when positioning a rack directly beside critical machinery like laser cutters, turret punches, shears, or press brakes. With sheets pre-staged and instantly reachable, machine downtime during material swaps drops dramatically—sometimes by more than half.

Built for Real-World Demands

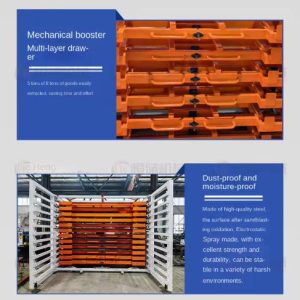

Every Herochu drawer rack features:

- All-welded steel construction for structural integrity under heavy cyclic loads

- Optional steel decking for added support on thinner or perforated sheets

- Powder-coated finish for corrosion and scratch resistance in oily or humid shop environments

- Integrated pull-out mechanism requiring minimal force, even at full capacity

Standard models like the HC-B3015-63 (3m x 1.5m, 6 layers, 3T) and HC-B6020-66 (6m x 2m, 6 layers, 6T) accommodate plate sizes from 2000×1500 mm up to 6000×2000 mm, with inter-layer clearances ranging from 150 mm to 390 mm—enough room to store multiple thicknesses without contact damage.

The bottom drawer sits 355 mm above ground, allowing easy access for cranes or lifters, while the top shelf reaches just under 2.2 meters, keeping everything within safe ergonomic reach or crane range.

Customization That Fits Your Workflow

Need a non-standard width? A specific color for zone identification? Higher load capacity per layer? Herochu offers full customization on dimensions, layer count (typically 4–8 shelves), load rating (up to 6 metric tons per drawer), and surface treatment. Whether you’re storing stainless steel blanks, aluminum composites, or galvanized roofing panels, we’ll configure a system that matches your material flow—not the other way around.

Safety, Space, and Speed—All in One

By moving sheet storage off the floor and into vertical, roll-out drawers, shops gain:

- Reduced manual handling injuries (no more bending, dragging, or lifting heavy sheets)

- Faster material retrieval (full extension = instant access)

- Smaller footprint (store 6+ material types in under 3 m²)

- Better housekeeping (no scattered offcuts or unstable stacks)

Backed by CE and ISO certifications, and manufactured in our Jinan facility with strict quality controls, every Herochu drawer rack is tested under full load before shipment.

For fabricators serious about lean operations, this isn’t just storage—it’s a strategic upgrade.

Factory

Hot Selling Machines

-

Heavy Duty Sheet Metal Storage Racks

Intelligent Production Line CNC Automated Storage Rack: Precision Meets Automation

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drawer-Style Sliding Sheet Metal Storage Rack – Efficient & Safe Material Handling

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Design for Steel Plate Storage with Heavy Duty Drawer Type Sheet Metal Rack Storage System

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Rack for Heavy Plates and Molds: Durable, Efficient Storage for Industrial Applications

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drive-In Pallet Rack Alternative: Space-Saving Drawer-Type Sheet Metal Storage with Automated Retrieval Compatibility

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Drawer Type Plate Shelves Warehouse Rack System for Industrial Metal Storage – 3-Ton Capacity per Layer

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Warehouse Storage System: Customizable Solutions for Metal Plate & Industrial Storage

Read moreRated 0 out of 5 -

Automated Storage Systems

Smart Fixed Profile Stereo Warehouse: Cost-Effective Automation for Small to Mid-Sized Fabrication Shops

Read moreRated 0 out of 5

Related products

Related products

-

Heavy Duty Sheet Metal Storage Racks

High-Density Sheet Metal Shelf Warehouse Solution

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sheet Metal Racking System That Works as Hard as Your Team

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy Duty Drawer Type Sheet Metal Shelves – The Smart Alternative to Floor Stacking

Read moreRated 0 out of 5