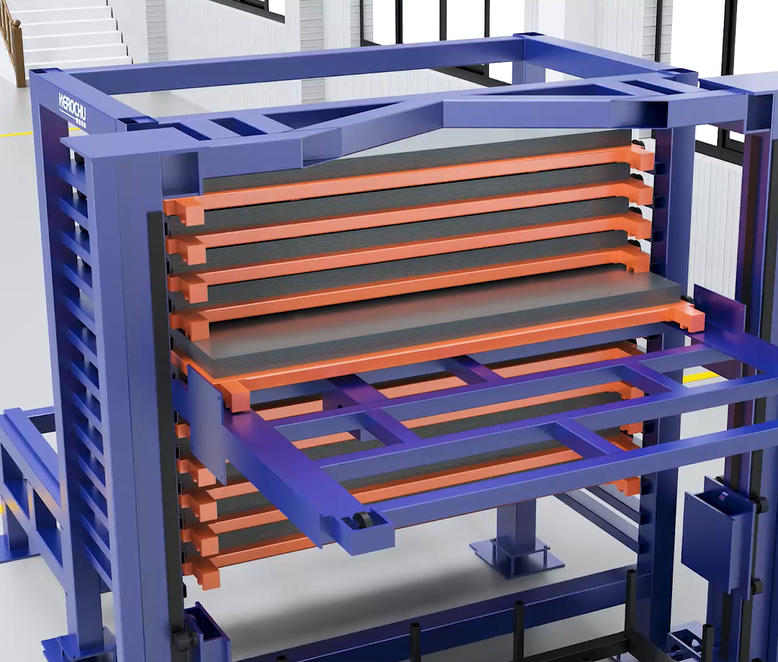

Heavy Duty Forklift Board Storage Rack

The backbone of the Herochu Forklift Board Rack lies in its meticulously engineered main frame, constructed from high-strength Q235B hot-rolled steel. This material choice ensures exceptional load-bearing capacity, with each rack capable of supporting weights ranging from 1 to 5 tons, depending on the configuration. The crossbeams and longitudinal beams are strategically welded into a grid or diamond-shaped structure, providing a stable platform that prevents plate displacement during handling. This design not only enhances safety but also ensures consistent performance under demanding conditions.

Herochu Heavy Duty Forklift Board Storage Rack: The Ultimate Workshop Solution for Efficient Plate Storage

In today’s fast-paced industrial landscape, where efficiency and safety are paramount, the Herochu Heavy Duty Forklift Board Storage Rack emerges as a transformative solution for workshops across manufacturing, warehousing, and logistics sectors. This innovative storage system is meticulously designed to handle a diverse array of materials—including steel, aluminum, wood, and plastic plates—with unparalleled durability and adaptability. Priced competitively starting at $5,499, this rack isn’t just a storage accessory; it’s a strategic investment that redefines operational workflows, minimizes downtime, and maximizes productivity.

Structural Characteristics: Engineering Excellence for Heavy-Duty Applications

Main Frame Design: Strength Meets Precision

The backbone of the Herochu Forklift Board Rack lies in its meticulously engineered main frame, constructed from high-strength Q235B hot-rolled steel. This material choice ensures exceptional load-bearing capacity, with each rack capable of supporting weights ranging from 1 to 5 tons, depending on the configuration. The crossbeams and longitudinal beams are strategically welded into a grid or diamond-shaped structure, providing a stable platform that prevents plate displacement during handling. This design not only enhances safety but also ensures consistent performance under demanding conditions.

The rack’s bottom features forklift fork holes, typically designed as front and rear types, with heights optimized for standard forklift forks (usually between 100-150mm). This thoughtful incorporation facilitates quick and seamless picking and handling, significantly reducing operational bottlenecks and enhancing overall workflow efficiency.

Anti-Slip and Protective Design: Safety First

Safety is non-negotiable in industrial environments, and the Herochu Forklift Board Rack excels in this regard. The surface of the plate or crossbeam is equipped with anti-slip rubber pads, strip-shaped protrusions, or welded guard strips. These features work in tandem to prevent plates from sliding or shifting during transportation, ensuring a secure hold even on uneven surfaces. Additionally, the edges are rounded off to eliminate sharp corners, protecting both operators and the surface of the plates from scratches or injuries. This emphasis on safety not only reduces workplace accidents but also prolongs the lifespan of the stored materials.

Customizable Structure: Tailored to Your Needs

Recognizing that every workshop has unique requirements, the Herochu Forklift Board Rack offers unparalleled customization options. The frame length and width can be tailored to accommodate various plate sizes, including common specifications like 2000mm×1500mm or 1200mm×1000mm. For added versatility, some models come with foldable guardrails or fences, which fix the plates firmly in place and prevent tipping during handling. This adaptability makes the rack suitable for a wide range of applications, from small-scale operations to large industrial facilities, ensuring seamless integration into existing workflows.

Core Functions and Advantages: Elevating Operational Efficiency

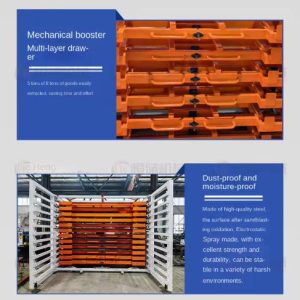

Efficient Loading and Unloading: Revolutionizing Workflows

One of the standout features of the Herochu Forklift Board Rack is its ability to revolutionize loading and unloading processes. When used in conjunction with forklifts, it enables mechanized handling, drastically reducing reliance on manual labor. Compared to traditional methods, this approach can save over 70% in labor costs, making it especially beneficial for long-distance transportation of heavy plates. Moreover, the rack allows for direct stacking of the plate frame along with the plates, eliminating the need for repeated loading and unloading. This not only enhances efficiency but also minimizes material loss and damage, ensuring cost-effective operations.

Flexible and Adaptable to Various Scenarios: Versatility at Its Best

The versatility of the Herochu Forklift Board Rack makes it indispensable across multiple industries. In the manufacturing sector, it serves as an ideal solution for temporary storage of plates in workshops and during process turnover. For instance, it facilitates seamless transfer from cutting machines to processing equipment, ensuring smooth workflow continuity. In warehousing and logistics, the rack can be combined with shelves to achieve vertical storage of plates, optimizing space utilization. Alternatively, it can be placed directly on the ground as a temporary storage tool, offering flexibility in storage arrangements. In building materials markets, the rack enhances service efficiency by enabling quick loading and unloading for customers, allowing them to select plates on-site with ease. This adaptability ensures that the rack remains a valuable asset in diverse operational contexts.

Protecting Plate Quality: Ensuring Longevity

Maintaining the integrity of your plates is crucial, and the Herochu Forklift Board Rack excels in this regard. The flat surface of the frame ensures that plates are not exposed to ground contact, thereby preventing scratches, deformation, or moisture damage. For organizations dealing with multiple plate specifications, the partitioned design of the rack allows for simultaneous storage of various types, eliminating the need for mixed placement and reducing the risk of collision-related damage. This focus on quality protection ensures that your materials remain in pristine condition, ready for immediate use.

Low Cost and High Durability: Smart Investment

Despite its advanced features, the Herochu Forklift Board Rack is incredibly cost-effective, especially when compared to customized shelves. Its simple structure and low manufacturing cost make it an attractive option for small and medium-sized enterprises looking to enhance their storage capabilities without breaking the bank. The rack’s surface is treated with powder coating, galvanizing, or electroplating, providing strong corrosion resistance and extending its service life to 5-10 years. This durability ensures long-term value, making it a smart investment for any operation.

Certification and Quality Assurance: Trusted Performance

Quality is non-negotiable, and the Herochu Forklift Board Storage Rack is CE, UE, and ISO 9001 certified. These certifications attest to the rack’s compliance with international safety and quality standards, giving you peace of mind that you’re investing in a product that meets the highest benchmarks. Whether you’re in a bustling manufacturing facility or a dynamic logistics hub, you can trust the Herochu Forklift Board Rack to deliver consistent and reliable performance.

Conclusion: A Strategic Upgrade for Your Workshop

The Herochu Heavy Duty Forklift Board Storage Rack is more than just a storage solution; it’s a transformative tool designed to enhance efficiency, safety, and cost-effectiveness in your operations. With its robust construction, customizable features, and wide-ranging applications, it’s tailored to meet the diverse needs of manufacturing, warehousing, logistics, and building materials industries. By investing in this rack, you’re not only optimizing your storage capabilities but also future-proofing your operations against evolving challenges. Embrace the Herochu Forklift Board Storage Rack and experience the difference it can make in your workshop today.

Factory

Hot Selling Machines

-

Heavy Duty Sheet Metal Storage Racks

Intelligent Production Line CNC Automated Storage Rack: Precision Meets Automation

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drawer-Style Sliding Sheet Metal Storage Rack – Efficient & Safe Material Handling

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Design for Steel Plate Storage with Heavy Duty Drawer Type Sheet Metal Rack Storage System

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Rack for Heavy Plates and Molds: Durable, Efficient Storage for Industrial Applications

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drive-In Pallet Rack Alternative: Space-Saving Drawer-Type Sheet Metal Storage with Automated Retrieval Compatibility

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Drawer Type Plate Shelves Warehouse Rack System for Industrial Metal Storage – 3-Ton Capacity per Layer

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Warehouse Storage System: Customizable Solutions for Metal Plate & Industrial Storage

Read moreRated 0 out of 5 -

Automated Storage Systems

Smart Fixed Profile Stereo Warehouse: Cost-Effective Automation for Small to Mid-Sized Fabrication Shops

Read moreRated 0 out of 5

Related products

Related products

-

Heavy Duty Sheet Metal Storage Racks

Industrial Multi-Layer Sheet Metal Storage Rack

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy Duty Forklift aluminum plates storage equipment

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

High-Density Sheet Metal Shelf Warehouse Solution

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy Duty Shelves Built for Sheet Metal—Not Afterthoughts

Read moreRated 0 out of 5