Heavy Duty Forklift Sheet Metal Storage Rack by Herochu

If you’ve ever watched a forklift operator struggle to lift a wobbling stack of steel plates—or seen a $2,000 aluminum sheet get scratched because it was leaning against a concrete wall—you know that how you store your materials matters just as much as how you cut, bend, or ship them. That’s where the Herochu Heavy Duty Forklift Sheet Metal Storage Rack comes in: not as an accessory, but as a foundational piece of your material handling strategy.

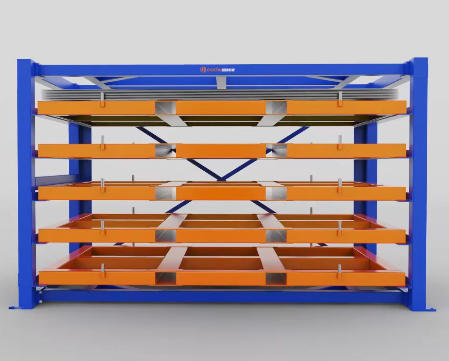

Heavy Duty Forklift Sheet Metal Storage Rack by Herochu – Precision-Built for Industrial Demands

If you’ve ever watched a forklift operator struggle to lift a wobbling stack of steel plates—or seen a $2,000 aluminum sheet get scratched because it was leaning against a concrete wall—you know that how you store your materials matters just as much as how you cut, bend, or ship them. That’s where the Herochu Heavy Duty Forklift Sheet Metal Storage Rack comes in: not as an accessory, but as a foundational piece of your material handling strategy.

Starting at $5,499, and fully compliant with CE, UE, and ISO 9001 standards, this rack is engineered from the ground up for shops, warehouses, and distribution centers that demand reliability without unnecessary complexity.

Structure That Stands Up to Real Work

Forget bolt-together kits that rattle under load. The Herochu forklift rack is fabricated from Q235B hot-rolled structural steel, known for its consistent yield strength and weld integrity. The frame isn’t just strong—it’s intelligently braced. Crossbeams and longitudinal supports are arranged in either a reinforced grid or diamond truss pattern, depending on your plate dimensions and weight profile. This design distributes stress evenly, preventing sagging or torsional twist even when loaded near capacity.

Each unit is rated for 1 to 5 metric tons, with exact specs tailored to your use case. Whether you’re moving 6mm carbon steel blanks or 12-foot composite panels, we configure beam spacing, frame depth, and reinforcement accordingly.

Critically, the base includes dual-direction forklift entry pockets—front and rear,贯通 (through-type)—machined to accept standard fork thicknesses (100–150mm). No adapters. No tilting. Just stable, centered lifting on the first try.

Designed to Protect—Not Just Hold

Material damage often starts before processing even begins. Ground contact invites moisture, dirt, and warping. Unsecured stacks shift during transport, causing edge dings or surface marring. Herochu addresses these issues proactively:

- Non-slip surfaces: Choose from vulcanized rubber strips, welded anti-slide ribs, or textured powder-coated zones to keep plates firmly in place.

- Smooth, rounded edges: All structural corners are deburred and chamfered during fabrication—protecting both your workforce and your high-value stock.

- Optional fold-down side guards: For taller or mixed-size loads, add hinged rails that lock upright during transit and fold flat when not in use—ideal for tight aisles or multi-use racks.

By keeping sheets elevated, aligned, and isolated from floor hazards, the rack preserves dimensional accuracy and surface finish—critical for industries like architectural metalwork, precision machining, or automotive trim.

Customization Without Compromise

We don’t sell “one-size-fits-most.” Your workflow is unique, so your storage should be too.

Standard platform sizes include 2000mm × 1500mm and 1200mm × 1000mm, but we routinely build to non-standard footprints—whether you’re handling oversized marine-grade plates or narrow-gauge strips for electronics housings. Need internal dividers to separate stainless from galvanized? Done. Want a specific powder coat color to match your facility coding? Included.

And because operations grow, our system is modular by design. Start with two racks today, integrate four more next quarter, and later connect them into a larger storage array—all with consistent compatibility and zero retrofitting.

Where It Delivers Tangible Value

This rack isn’t theoretical—it’s proven across sectors where efficiency and material integrity directly impact profitability:

- Metal Fabrication: Use it as a mobile buffer between cutting, bending, and welding stations. Load once, move seamlessly—eliminating double-handling and reducing cycle time.

- Warehousing & Logistics: Deploy as standalone ground storage near dispatch bays, or pair with pallet racking for vertical stacking. Forklift operators can move entire batches in one lift.

- Building Materials Retail: Display full sheets securely for customer selection—no more unstable leaning stacks or floor clutter. Improves safety, speeds service, and cuts damage-related returns.

- Heavy Machinery OEMs: Store wear plates, base frames, or structural components near assembly lines without blocking workflow or risking collapse.

One Midwest job shop reported a 71% reduction in handling labor and a near-elimination of surface damage claims within eight months of switching to Herochu racks. Their payback period? Under a year.

Built to Last—Without Constant Upkeep

Durability isn’t just about load ratings—it’s about resisting corrosion, impact, and daily wear. Every Herochu rack undergoes a three-stage surface treatment process:

- Alkaline cleaning and phosphate conversion coating for superior adhesion

- Electrostatic powder coating (or optional hot-dip galvanizing for outdoor/coastal use)

- High-temperature curing to create a chip-resistant, UV-stable finish

The result? A service life of 5 to 10 years, even in humid, oily, or chemically active environments. Compare that to untreated or lightly painted racks that rust, flake, or require repainting every 18 months.

And because there are no moving parts, hydraulics, or electronics, maintenance is straightforward: occasional visual checks and routine cleaning are all that’s needed.

Choosing the Right Rack—Without the Guesswork

When evaluating forklift-compatible storage, ask these key questions:

- Is the stated load capacity based on real-world testing—not just theoretical math?

- Do the fork pockets align with my existing forklift fleet?

- Can I modify dimensions without paying premium engineering fees?

- Are quality certifications backed by auditable processes?

At Herochu, we provide detailed CAD drawings, load validation reports, and virtual layout simulations before you place an order. Transparency isn’t a feature—it’s standard practice.

Final Word: Stop Managing Chaos. Start Moving with Control.

In high-turnover industrial environments, disorganized storage isn’t just messy—it’s expensive. Lost time. Damaged inventory. Safety near-misses. The Herochu Heavy Duty Forklift Sheet Metal Storage Rack turns those pain points into performance advantages: faster throughput, cleaner materials, safer floors, and scalable infrastructure.

Certified. Custom-fit. Built for the long haul. And priced from $5,499 to deliver immediate ROI.

Don’t just store your sheets—secure, organize, and mobilize them with purpose.

Herochu—engineered storage for serious operations.

Factory

Hot Selling Machines

-

Heavy Duty Sheet Metal Storage Racks

Intelligent Production Line CNC Automated Storage Rack: Precision Meets Automation

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drawer-Style Sliding Sheet Metal Storage Rack – Efficient & Safe Material Handling

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Design for Steel Plate Storage with Heavy Duty Drawer Type Sheet Metal Rack Storage System

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Rack for Heavy Plates and Molds: Durable, Efficient Storage for Industrial Applications

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drive-In Pallet Rack Alternative: Space-Saving Drawer-Type Sheet Metal Storage with Automated Retrieval Compatibility

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Drawer Type Plate Shelves Warehouse Rack System for Industrial Metal Storage – 3-Ton Capacity per Layer

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Warehouse Storage System: Customizable Solutions for Metal Plate & Industrial Storage

Read moreRated 0 out of 5 -

Automated Storage Systems

Smart Fixed Profile Stereo Warehouse: Cost-Effective Automation for Small to Mid-Sized Fabrication Shops

Read moreRated 0 out of 5

Related products

Related products

-

Heavy Duty Sheet Metal Storage Racks

Heavy Duty Steel Plate Warehouse Shelving Systems

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy Duty Forklift steel plates Storage Rack

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Roll Out Drawer Storage Rack – The End of “Where’s That Sheet?”

Read moreRated 0 out of 5