Maximizing Efficiency with Dual-Tower Automated Storage Solutions

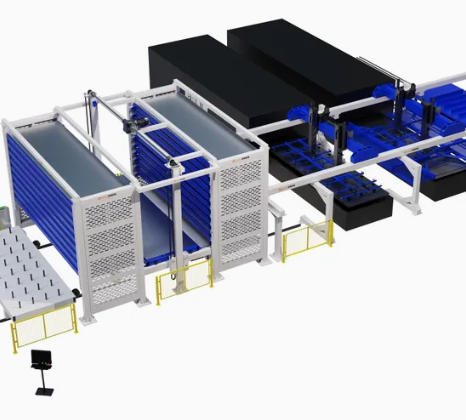

The Dual-Tower configuration fundamentally reimagines industrial storage by utilizing vertical space that traditional systems leave underutilized. While conventional static racks require expansive floor areas for material access and forklift maneuvering, the automated system consolidates storage into a compact footprint. Each tower functions as a high-density storage unit, with materials stacked vertically and accessed through precise automated retrieval.

In today’s competitive manufacturing landscape, optimizing material handling processes is crucial for maintaining productivity and profitability. The Dual-Tower Sheet Material Automated Storage and Retrieval System represents a paradigm shift in industrial storage, offering innovative solutions to age-old challenges in sheet metal management. This comprehensive system addresses the core pain points of modern fabrication facilities through its intelligent design and cutting-edge automation.

Space Optimization: Doing More with Less

Vertical Storage Revolution

The Dual-Tower configuration fundamentally reimagines industrial storage by utilizing vertical space that traditional systems leave underutilized. While conventional static racks require expansive floor areas for material access and forklift maneuvering, the automated system consolidates storage into a compact footprint. Each tower functions as a high-density storage unit, with materials stacked vertically and accessed through precise automated retrieval.

This vertical approach isn’t just about stacking materials higher – it’s about intelligent space utilization. The system’s design eliminates wasted aisle space between racks, as materials are delivered directly to operators at ground level. For facilities constrained by square footage, this means being able to store significantly more inventory without expanding physical plant size. The space savings translate directly into operational advantages, allowing manufacturers to reallocate valuable floor space for production equipment or additional workstations.

Footprint Flexibility for Diverse Operations

Understanding that manufacturing facilities come in various sizes and configurations, the system offers adaptable footprint options. Whether installed in a standalone position or integrated into existing production lines, the towers can be configured to complement facility layouts. This adaptability ensures that manufacturers aren’t forced to redesign their entire operations to accommodate new storage technology.

The system’s ability to fit into tight spaces while maintaining full functionality makes it ideal for urban manufacturing facilities where real estate comes at a premium. By maximizing storage capacity within existing structures, companies can avoid costly facility expansions or relocations, preserving capital for other strategic investments.

Advanced Material Handling Technology

Precision Engineering for Reliable Operations

At the core of the system’s efficiency is its sophisticated movement mechanism. The linear guide rail and chain drive system work in harmony to ensure smooth, precise vertical transitions between storage levels. This engineering precision minimizes vibration during material transfer, protecting sensitive sheet metal surfaces from potential damage during retrieval.

The chain drive transmission offers distinct advantages over alternative mechanisms. Its robust design ensures consistent performance even under heavy loads, while requiring minimal maintenance compared to other drive systems. This reliability translates into uninterrupted operations and reduced downtime for maintenance, keeping production schedules on track.

Optimized Speeds for Efficient Workflows

Balancing speed with precision, the system operates at an optimal vertical lifting speed of 9m/min and an inlet/outlet speed of 12m/min. These velocities are carefully calibrated to ensure quick material retrieval without compromising safety or control. Operators experience significantly reduced wait times compared to manual retrieval methods, leading to smoother material flow throughout the production process.

The system’s intelligent speed management adapts to operational demands, ensuring efficient throughput during peak periods while maintaining safe operation during lighter workloads. This dynamic capability makes it suitable for facilities with varying production schedules, providing consistent performance regardless of workload fluctuations.

Customizable Storage Solutions

Tailored Capacity Options

Recognizing that manufacturing operations have diverse material handling requirements, the system offers customizable load capacity per layer. With options for 3T or 5T capacity per storage level, facilities can configure the system to match their specific material weight requirements. This flexibility ensures optimal performance whether handling lightweight alloys or heavier steel plates.

The capacity customization extends to the overall system design, allowing manufacturers to select configurations that align with their average material sizes and production volumes. This tailored approach prevents over-engineering or underutilization of storage capacity, ensuring each system operates at peak efficiency.

Versatile Material Support

Understanding that different sheet metals require specific handling considerations, the system offers optional plate support features. These customizable support elements ensure proper material positioning during storage and retrieval, accommodating various sheet sizes and thicknesses. The ability to adapt to different material specifications makes the system suitable for diverse applications across industries, from automotive manufacturing to aerospace components production.

Operational Benefits Across Manufacturing Processes

Streamlined Material Flow

The system’s automated retrieval process eliminates bottlenecks in material movement. By delivering materials directly to operators at ground level, it removes the need for manual handling or forklift transport between storage and workstations. This seamless integration with production workflows reduces material handling time, allowing workers to focus on value-added tasks rather than material logistics.

The intelligent design ensures materials are presented in an ergonomic position for processing, reducing worker fatigue and improving overall production efficiency. Operators experience smoother transitions between tasks, with materials available precisely when needed in the production cycle.

Enhanced Workplace Safety

Safety considerations are integrated into every aspect of the system’s design. The enclosed structure protects workers from potential falling materials during retrieval, while the automated process eliminates the need for workers to climb or reach overhead for materials. By removing manual handling of heavy sheet metal loads, the system significantly reduces the risk of workplace injuries related to material transport.

The system’s safety features extend to its operational design, with built-in safeguards to prevent accidents during material transfer. These protections not only create a safer work environment but also contribute to reduced workers’ compensation claims and associated costs.

Long-Term Value Proposition

durability and Reliability

Built with industrial-grade components, the system is designed for long-term reliable operation in demanding manufacturing environments. The robust construction ensures durability against daily operational stresses, while requiring minimal maintenance compared to traditional storage solutions. This reliability translates into consistent performance over years of operation, providing a dependable material handling solution.

Return on Investment

While the system represents an investment in advanced technology, its operational benefits translate into measurable financial advantages. The space savings alone can provide significant cost benefits, particularly in high-cost real estate markets. Reduced material damage and improved workflow efficiency contribute to enhanced product quality and consistency, while decreased labor requirements for material handling offer additional cost savings.

The system’s ability to adapt to future production needs without requiring major facility modifications ensures long-term relevance, protecting manufacturers’ investments against changing operational requirements. When considering the total cost of ownership, the system’s efficiency gains and operational benefits typically result in a favorable return on investment over its lifespan.

Factory

Hot Selling Machines

-

Heavy Duty Sheet Metal Storage Racks

Intelligent Production Line CNC Automated Storage Rack: Precision Meets Automation

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drawer-Style Sliding Sheet Metal Storage Rack – Efficient & Safe Material Handling

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Design for Steel Plate Storage with Heavy Duty Drawer Type Sheet Metal Rack Storage System

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Rack for Heavy Plates and Molds: Durable, Efficient Storage for Industrial Applications

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drive-In Pallet Rack Alternative: Space-Saving Drawer-Type Sheet Metal Storage with Automated Retrieval Compatibility

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Drawer Type Plate Shelves Warehouse Rack System for Industrial Metal Storage – 3-Ton Capacity per Layer

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Warehouse Storage System: Customizable Solutions for Metal Plate & Industrial Storage

Read moreRated 0 out of 5 -

Automated Storage Systems

Smart Fixed Profile Stereo Warehouse: Cost-Effective Automation for Small to Mid-Sized Fabrication Shops

Read moreRated 0 out of 5

Related products

Related products

-

Automation Sheet Metal Material Warehouse

Multi-Tower Automated Storage Systems

Read moreRated 0 out of 5 -

Automation Sheet Metal Material Warehouse

Dual‑Tower Sheet Metal Storage Warehouse

Read moreRated 0 out of 5 -

Automation Sheet Metal Material Warehouse

Intelligent Automated Industrial Pipe Storage Warehouse

Read moreRated 0 out of 5 -

Automation Sheet Metal Material Warehouse

Fully Automatic Smart Industrial Long Material Warehouse

Read moreRated 0 out of 5