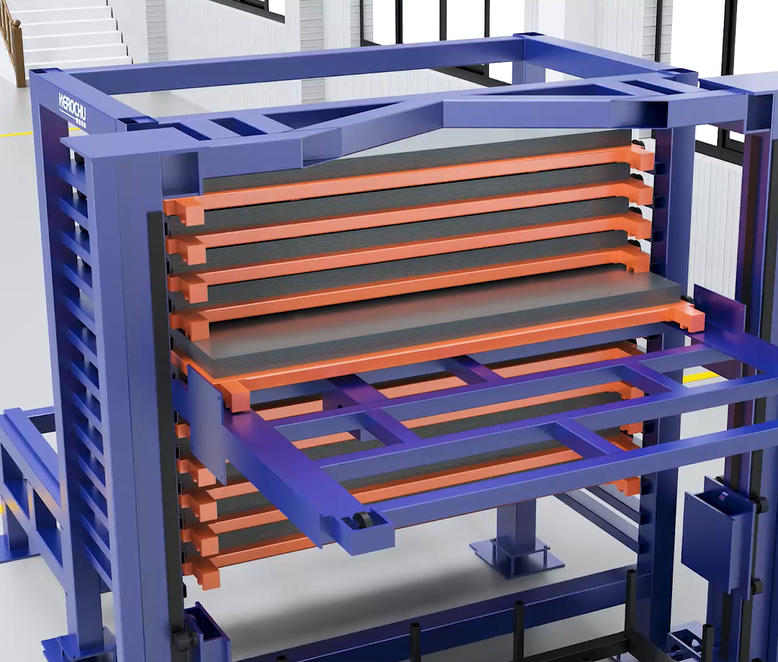

Metal plate depalletizer and material warehouse

In today’s fast-paced metal fabrication and manufacturing environments, efficiency, safety, and space optimization are non-negotiable. One often-overlooked yet critical component of the material handling process is how sheet metal is transferred from delivery pallets to storage racks—and back again. Enter the sheet metal depalletizer: a purpose-built pin table system engineered to transform your workflow from chaotic to controlled.

Streamline Your Metal Fabrication Workflow with a High-Efficiency Depalletizer

In today’s fast-paced metal fabrication and manufacturing environments, efficiency, safety, and space optimization are non-negotiable. One often-overlooked yet critical component of the material handling process is how sheet metal is transferred from delivery pallets to storage racks—and back again. Enter the sheet metal depalletizer: a purpose-built pin table system engineered to transform your workflow from chaotic to controlled.

A depalletizer isn’t just another piece of equipment—it’s a strategic investment in productivity. Specifically designed for seamless integration with steel rack pallet systems, this innovative solution allows operators to unload or reload sheet metal stacks quickly, safely, and without damaging the material. Unlike traditional methods that rely on manual lifting, overhead cranes, or forklift manipulation—each carrying risks of bending, scratching, or misalignment—the depalletizer uses a precisely spaced array of vertical pins to support the sheet evenly during transfer.

This even support is crucial. Sheet metal, especially large or thin-gauge panels, is highly susceptible to warping or surface damage when handled improperly. By eliminating direct contact with edges or uneven pressure points, the depalletizer preserves material integrity, directly reducing scrap rates and rework costs. For businesses operating on tight margins, even a 2–3% reduction in material waste can translate into significant annual savings.

But the benefits extend far beyond material preservation. Consider floor space—a premium commodity in any warehouse or shop floor. Traditional stacking methods often require wide aisles, extra clearance for forklifts, and sprawling horizontal layouts. The depalletizer enables vertical storage optimization by working hand-in-hand with high-density steel rack pallets. These racks can be stacked higher and organized more tightly, increasing storage capacity per square foot without expanding your physical footprint. In fact, many facilities report reclaiming up to 30% of previously underutilized floor area after implementing this system.

Organization is another major win. Gone are the days of rummaging through mixed piles of stainless, aluminum, and carbon steel sheets. With a depalletizer integrated into a numbered grid storage system, every sheet has a designated location. Inventory counts become faster and more accurate. Operators spend less time searching and more time producing. This structured approach also minimizes cross-contamination between material grades—a common issue in job shops handling diverse client specifications.

Safety improvements are perhaps the most compelling advantage. Manual handling of sheet metal poses serious hazards: sharp edges, heavy loads, unstable stacks, and tripping risks from loose materials scattered across the floor. The depalletizer mitigates these dangers by enabling single-operator material handling. Workers no longer need to wrestle with drooping sheets or balance precarious loads. Edges remain shielded within the rack structure, and the entire transfer process occurs at a controlled, ergonomic height. Fewer injuries mean lower insurance premiums, reduced downtime, and a healthier workplace culture.

Moreover, the depalletizer supports lean manufacturing principles. By standardizing the material transfer process, it reduces cycle times and eliminates bottlenecks at the receiving or staging areas. Whether you’re running just-in-time production or managing high-volume batch jobs, consistent, predictable material flow is essential—and the depalletizer delivers exactly that.

Implementation is straightforward. Most systems are modular and customizable to accommodate various sheet sizes, thicknesses, and weights. Integration with existing racking infrastructure is typically seamless, and training takes mere hours—not days. Many users report full ROI within 6 to 12 months due to labor savings, reduced waste, and increased throughput.

In summary, the sheet metal depalletizer is far more than a convenience—it’s a cornerstone of modern, efficient, and safe metal fabrication operations. If your facility still relies on outdated handling methods, it may be time to evaluate how this technology can elevate your productivity, protect your workforce, and maximize your spatial resources. Reach out to a trusted supplier today to explore configurations tailored to your specific workflow needs.

Factory

Hot Selling Machines

-

Heavy Duty Sheet Metal Storage Racks

Intelligent Production Line CNC Automated Storage Rack: Precision Meets Automation

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drawer-Style Sliding Sheet Metal Storage Rack – Efficient & Safe Material Handling

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Design for Steel Plate Storage with Heavy Duty Drawer Type Sheet Metal Rack Storage System

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Sliding Drawer Rack for Heavy Plates and Molds: Durable, Efficient Storage for Industrial Applications

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Drive-In Pallet Rack Alternative: Space-Saving Drawer-Type Sheet Metal Storage with Automated Retrieval Compatibility

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Drawer Type Plate Shelves Warehouse Rack System for Industrial Metal Storage – 3-Ton Capacity per Layer

Read moreRated 0 out of 5 -

Heavy Duty Sheet Metal Storage Racks

Heavy-Duty Warehouse Storage System: Customizable Solutions for Metal Plate & Industrial Storage

Read moreRated 0 out of 5 -

Automated Storage Systems

Smart Fixed Profile Stereo Warehouse: Cost-Effective Automation for Small to Mid-Sized Fabrication Shops

Read moreRated 0 out of 5

Related products

Related products

-

Automated Storage Systems

Automated Storage Rack System for Sheet Metal – Cost-Effective and Flexible Solution for Medium and Small-Scale Enterprises

Read moreRated 0 out of 5